Bacteriostatic hand-washing soap piece and preparation method thereof

A technology of soap flakes and antibacterial agents, which is applied in the field of antibacterial hand soap flakes and its preparation, can solve the problems that hand sanitizers are difficult to maintain cleanliness, reduce skin irritation, and reduce product consistency. It is suitable for large-scale mass production, Accelerate molecular thermal movement and reduce irritation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

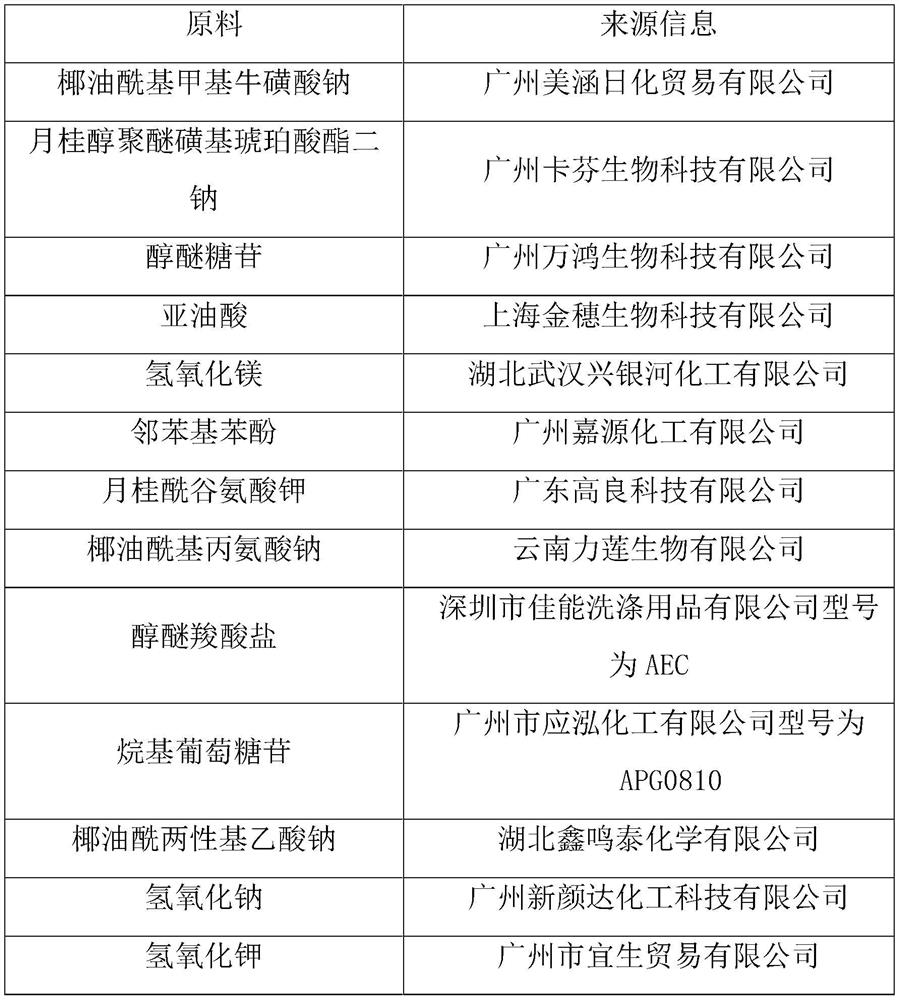

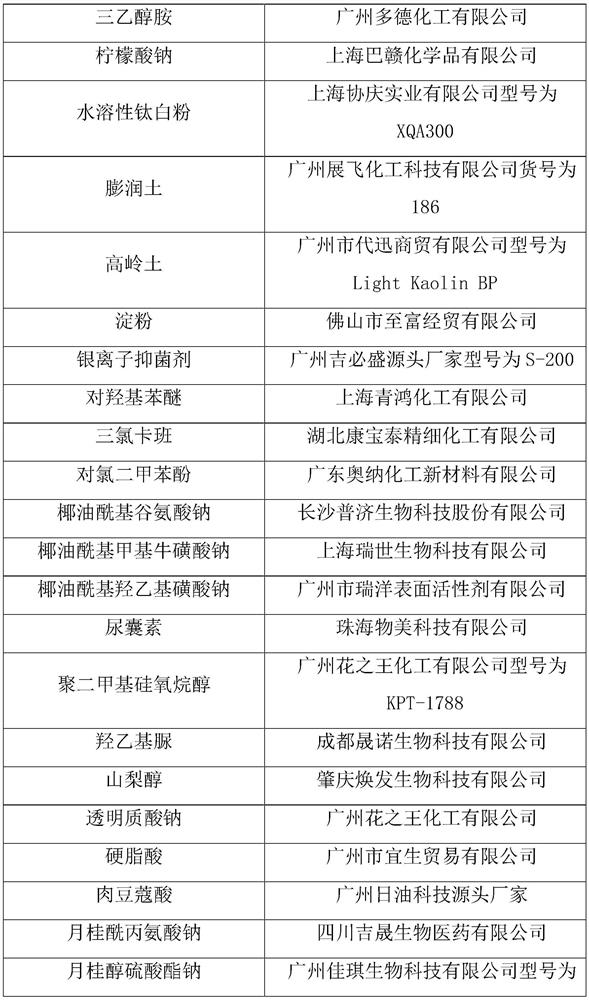

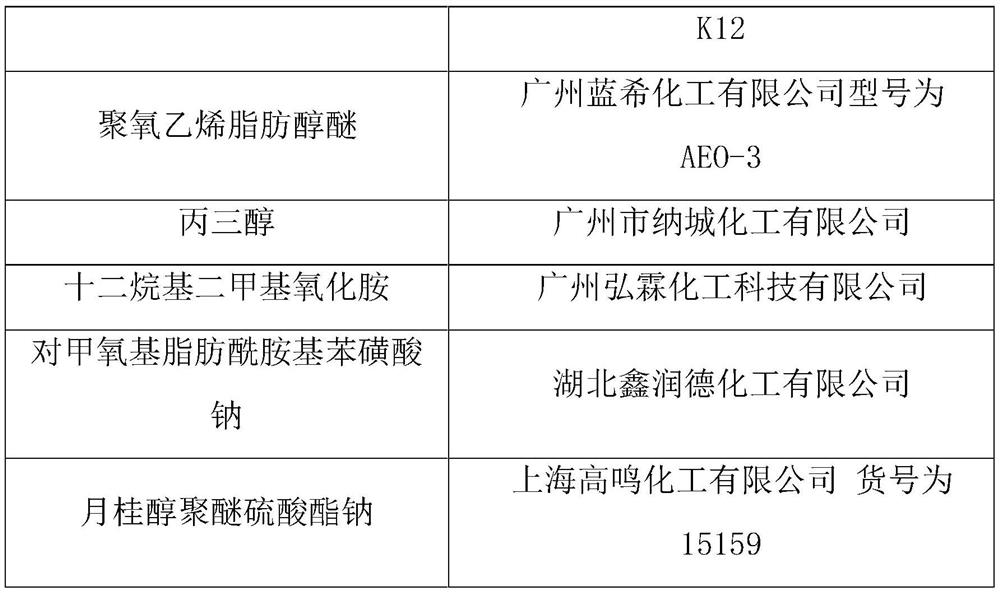

Method used

Image

Examples

Embodiment 1

[0069] A kind of antibacterial hand soap sheet, comprising 38kg of film-forming agent, 3kg of amino acid surfactant, 5kg of anionic surfactant, 2kg of nonionic surfactant, 1kg of fatty acid, 0.1kg of alkali, 0.05kg of Antibacterial agent, 2kg of additives, 2kg of additives, 46.85kg of water.

[0070] The film-forming agent consists of 35kg of polyvinyl alcohol and 3kg of polyvinylpyrrolidone.

[0071] The polyvinyl alcohol in this embodiment is the polyvinyl alcohol of the model BF24 purchased from Guangzhou Zhonggao Chemical Co., Ltd. The degree of alcoholysis of the polyvinyl alcohol of BF24 is 98.5%-99.2%, and the average degree of polymerization is 2400. The molecular weight is 105600.

[0072] The polyvinylpyrrolidone in this embodiment is polyvinylpyrrolidone purchased from Twin International Co., Ltd. with the product name PVP K12, and the K value of the polyvinylpyrrolidone in PVP K12 is 10.2-13.8.

[0073] The amino acid surfactant is sodium cocoyl methyl taurate. ...

Embodiment 2

[0088] Compared with Example 1, the difference is only in:

[0089] The addition amount of film forming agent is 6kg, the addition amount of amino acid surfactant is 8kg, the addition amount of anionic surfactant is 6kg, the addition amount of nonionic surfactant is 5kg, the addition amount of fatty acid is 4kg, the addition amount of alkali The addition amount is 3kg, the addition amount of antibacterial agent is 2kg, the addition amount of auxiliary agent is 3kg, the addition amount of admixture is 3kg, the addition amount of water is 60kg.

[0090] The film-forming agent consists of 3kg of polyvinyl alcohol and 3kg of polyvinylpyrrolidone.

Embodiment 3

[0092] Compared with Example 1, the difference is only in:

[0093] The addition amount of film forming agent is 6.2kg, the addition amount of amino acid surfactant is 3.3kg, the addition amount of anionic surfactant is 25kg, the addition amount of nonionic surfactant is 2.3kg, and the addition amount of fatty acid is 10kg , The addition amount of alkali is 0.3kg, the addition amount of antibacterial agent is 0.08kg, the addition amount of auxiliary agent is 2.3kg, the addition amount of admixture is 2.5kg, the addition amount of water is 48.02kg.

[0094] The film-forming agent consists of 3.2kg of polyvinyl alcohol and 3kg of polyvinylpyrrolidone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com