Method for accelerating plasma nitriding with assistance of rare earth compound

A technology of rare earth compounds and plasma, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of nitride layer grain growth, reduce production efficiency, increase energy consumption, etc., and achieve hardness Improve and reduce nitriding cost and energy consumption, and improve the effect of bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

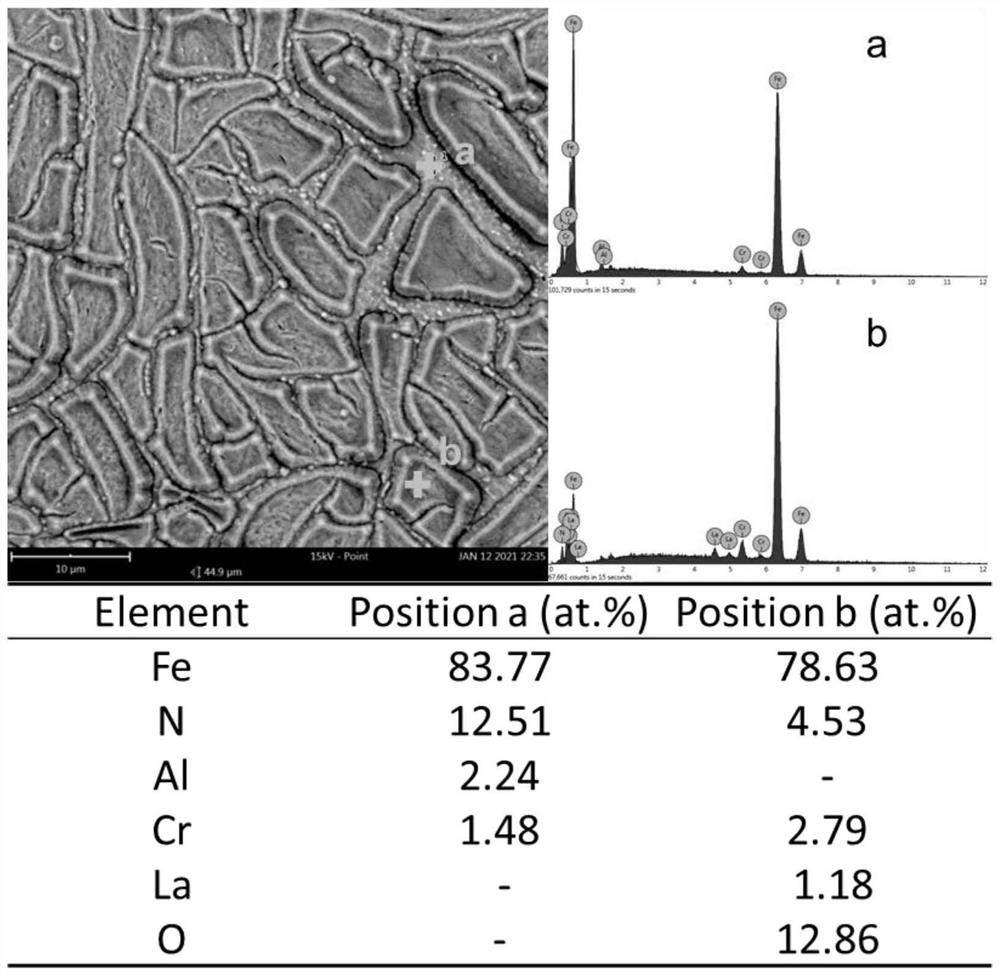

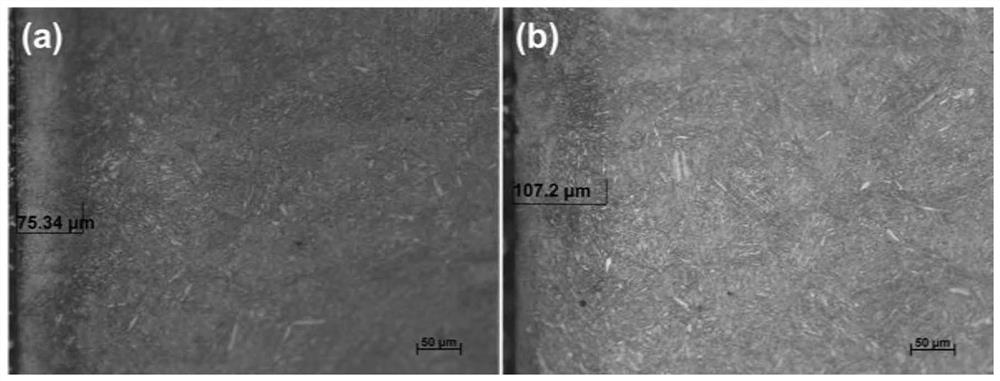

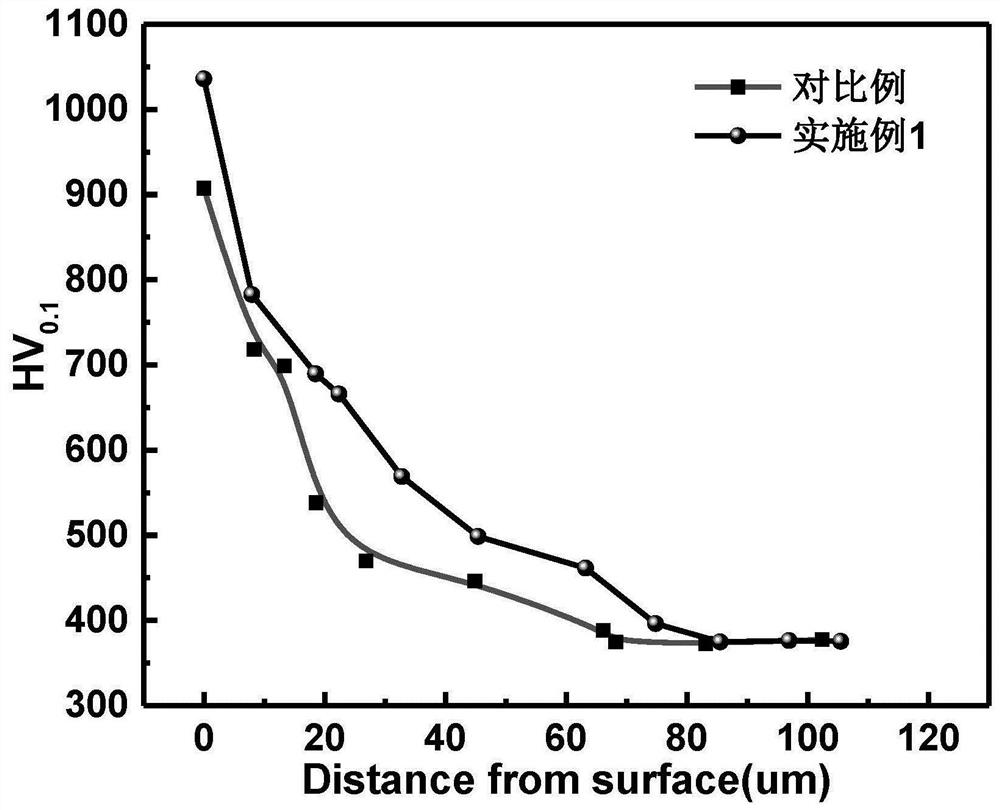

Embodiment 1

[0024] Step 1: Grind the 38CrMoAl steel sample with sandpaper, and further polish it to a mirror state, and clean it in acetone or alcohol solution;

[0025] Step 2: Weigh La(NO 3 ) 3 ·6H 2 O (99.99%, 0.02mol), Fe (NO 3 ) 3 9H 2 O (98.5%, 0.02mol) makes the mol ratio of lanthanum ion and iron ion be 1:1, adds 50mL distilled water and stirs constantly to make main salt dissolve, adds excess citric acid (10g) and stirs for two hours to make iron ion and lanthanum The ions are fully complexed, and a transparent rare earth compound LaFeO is formed after standing for 48 hours 3 Precursor solution;

[0026] Step 3: Prepare a rare earth compound film (thickness less than 5 μm) on the surface of the sample in step 1 by means of a suspension coating method (suspension coating machine 4000r / min);

[0027] Step 4: Put the sample into the furnace, feed nitrogen and hydrogen, and carry out plasma nitriding on the sample coated in step 3. The nitriding temperature is 520° C., and the...

Embodiment 2

[0030] Step 1: Grind the 38CrMoAl steel sample with sandpaper, and further polish it to a mirror state, and clean it in acetone or alcohol solution;

[0031] Step 2: Weigh La(NO 3 ) 3 ·6H 2 O (99.99%, 0.02mol), Fe (NO 3 ) 3 9H 2 O (98.5%, 0.02mol) makes the mol ratio of lanthanum ion and iron ion be 1:1, adds 50ml distilled water and stirs constantly to make main salt dissolve, adds excess citric acid (10g) and stirs for two hours to make iron ion and lanthanum The ions are fully complexed, and a transparent rare earth compound LaFeO is formed after standing for 48 hours 3 Precursor solution;

[0032] Step 3: Prepare a rare earth compound film (thickness less than 5 μm) on the surface of the sample in step 1 by means of a suspension coating method (6000 r / min of the suspension coating machine);

[0033] Step 4: Put the sample into the furnace, feed nitrogen and hydrogen, and carry out plasma nitriding on the sample coated in step 3. The nitriding temperature is 520° C.,...

Embodiment 3

[0035] Step 1: Grind the 38CrMoAl steel sample with sandpaper, and further polish it to a mirror state, and clean it in acetone or alcohol solution;

[0036] Step 2: Weigh Ce(NO 3 ) 3 ·6H 2 O (99.99%, 0.02mol), Fe (NO 3 ) 3 9H 2 O (98.5%, 0.02mol) makes the mol ratio of lanthanum ion and iron ion be 1:1, adds 50ml distilled water and stirs constantly to make main salt dissolve, adds excess citric acid (10g) and stirs for two hours to make iron ion and cerium The ions are fully complexed, and a transparent rare earth compound CeFeO is formed after standing for 48 hours 3 Precursor solution;

[0037] Step 3: Prepare a rare earth compound film (thickness less than 5 μm) on the surface of the sample in step 1 by means of suspension coating;

[0038] Step 4: Put the sample into the furnace, feed nitrogen and hydrogen, and carry out plasma nitriding on the sample coated in step 3. The nitriding temperature is 520° C., and the nitriding time is 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com