Two-way water stop gate with discrete sealing adjustment structure

A structure-adjusting, discrete technology, applied to waterway systems, water supply devices, buildings, etc., can solve problems such as increased gate maintenance costs and maintenance workload, increased pressure-bearing plate manufacturing costs, and problems with gate seals to achieve maintenance costs Inexpensive, avoid loose fit, proper spacing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing. The present invention will be further described.

[0025] Concrete implementation structure of the present invention is as follows:

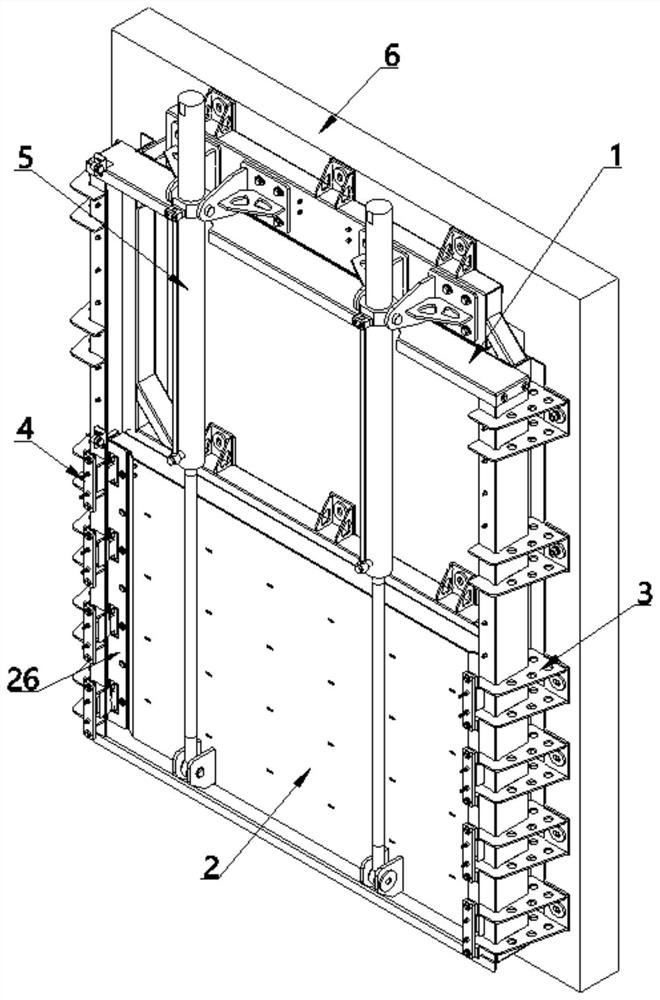

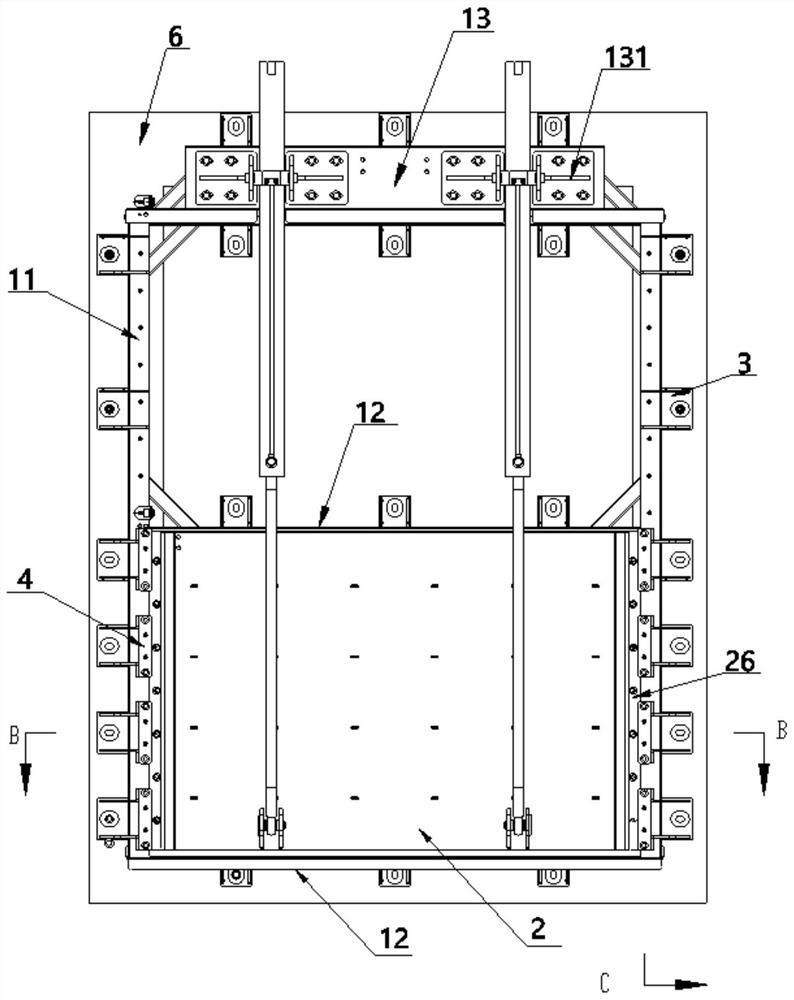

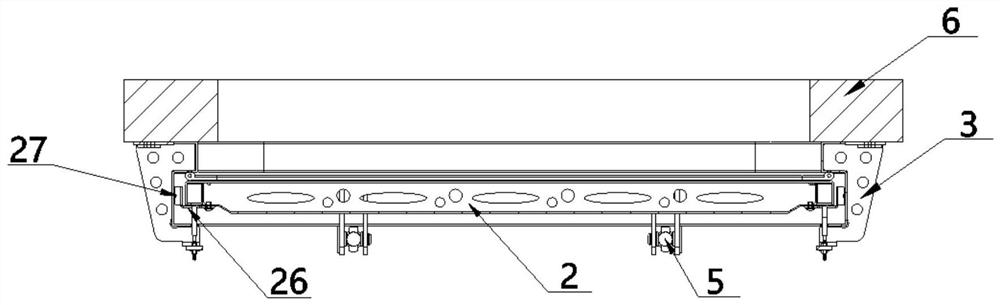

[0026] Such as figure 1 As shown, a two-way water-stop gate with a discrete seal adjustment structure includes a door frame 1, a gate 2, a door frame fixing seat 3, a seal adjustment mechanism 4 and a hydraulic drive rod 5. The door frame 1 is fixed on the civil construction base 6 by the door frame fixing seat 3, the gate 2 is installed in the door frame 1, and the lower part of the door frame 1 is equipped with a sealing adjustment mechanism 4, and the gate 2 is pressed on the door frame by the sealing adjustment mechanism 4, and is hydraulically driven. The oil cylinder end of rod 5 is fixed on the top of door frame 1, and its telescopic rod end is connected with gate 2.

[0027] Explain each important part of this gate separately below in conjunction with accompanying drawing.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com