Automatic calibration method and device for infrared temperature measurement equipment

An infrared temperature measurement and automatic calibration technology, which is applied in the field of temperature measurement to achieve the effect of improving calibration work efficiency, improving accuracy and calibration efficiency, and avoiding calibration deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

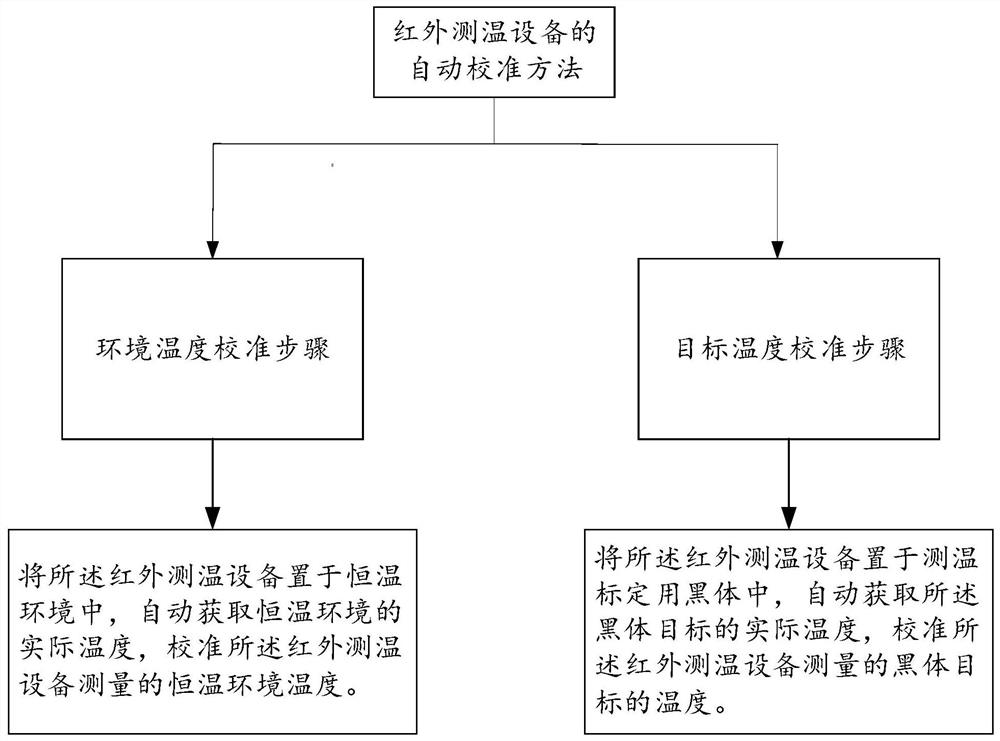

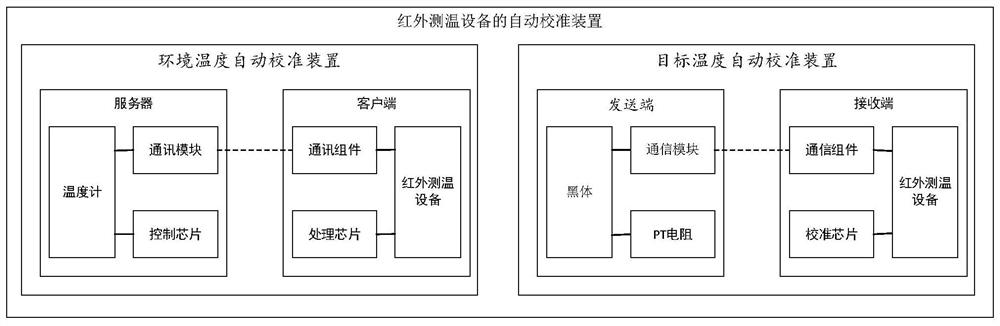

[0037] Embodiment 1: The automatic calibration method of infrared temperature measuring equipment in this embodiment includes the following steps: an ambient temperature calibration step and a target temperature calibration step.

[0038] The ambient temperature calibration step includes: placing the infrared temperature measuring device in a constant temperature environment, measuring the actual temperature of the constant temperature environment at multiple points, and automatically judging whether the constant temperature environment is in a stable state of thermal balance, and when it is judged to be in a stable state, then The actual temperature of the constant temperature environment is automatically obtained through the communication module; otherwise, the actual temperature of the constant temperature environment is continuously measured at multiple points until the judgment result is in a stable state, and the actual temperature of the constant temperature environment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com