Fuel assembly with compact structure, reactor and mobile carrier

A technology of fuel assembly and compact structure, which is applied in related fields of reactors, can solve the problems of complex flow regulation structure, increase the amount of structural materials, unfavorable core miniaturization, etc., achieve the effect of reducing structural materials, simplifying structural design, and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

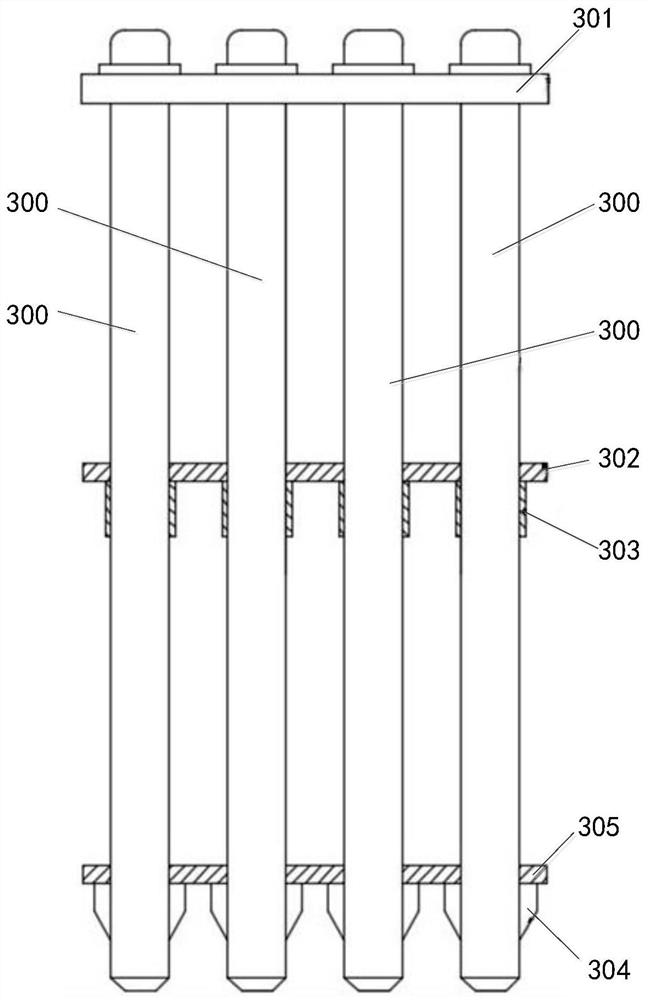

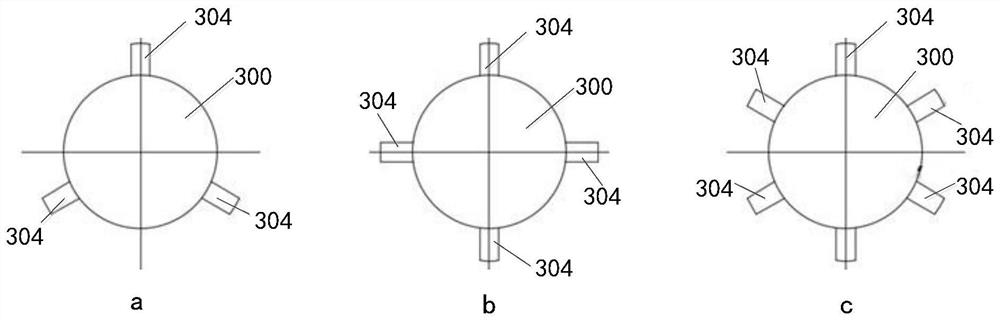

[0028] Such as figure 1 and figure 2 As shown, a fuel assembly with a compact structure in this embodiment includes a nuclear fixing plate 301, a number of fuel rods 300, a first guide plate 302, a support ring 303 and a throttle fin 304, and the throttle fin 304 is fixed on On the outer wall of one end of the fuel rods 300, several fuel rods 300 are respectively sleeved with support rings 303, and the first guide plate 302 is passed through several fuel rods 300 and supported on the support rings 303 The other end of the fuel rod 300 is assembled and fixed on the nuclear fixing plate 301; the first guide plate 302 and the support ring 303 are respectively made of core coolant, which has good safety, and the first guide plate Even if the 302 and the support ring 303 accidentally fall into the pile, they will melt by themselves before operation, and will not affect the safety of the equipment in the pile.

[0029] A fuel assembly with a compact structure in this embodiment h...

Embodiment 2

[0032] Such as figure 1 and figure 2 As shown, a fuel assembly with a compact structure in this embodiment includes a nuclear fixing plate 301, a number of fuel rods 300, a first guide plate 302, a support ring 303 and a throttle fin 304, and the throttle fin 304 is fixed on On the outer wall of one end of the fuel rods 300, several fuel rods 300 are respectively sleeved with support rings 303, and the first guide plate 302 is passed through several fuel rods 300 and supported on the support rings 303 The other end of the fuel rod 300 is assembled and fixed on the nuclear fixing plate 301; the first guide plate 302 and the support ring 303 are respectively made of core coolant, which has good safety, and the first guide plate Even if the 302 and the support ring 303 accidentally fall into the pile, they will melt by themselves before operation, and will not affect the safety of the equipment in the pile.

[0033] Such as figure 1 As shown, the fuel assembly with a compact ...

Embodiment 3

[0043] A reactor in this embodiment includes the above-mentioned compact fuel assembly. The upper ends of the fuel rods in the reactor of this embodiment are restrained and fixed by the fixing plate, the first guide plate constrains the middle part of the fuel rod, and the first guide plate located in the middle of the fuel rod is limited and supported by the support ring, and the first guide plate The core coolant and the support ring are respectively made of core coolant, which is solid at room temperature to realize the guiding function. It is melted before operation to avoid affecting the flow of core coolant, further reducing the impact on the flow of core coolant, and avoiding the impact of structural materials on neutrons. adverse effect on performance. The throttling fins can change the coolant flow area to realize core flow regulation. The invention minimizes structural materials, solves the problem of fixed support and compactness of the fuel assembly, and changes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com