On-line multi-point gas sampling analysis system and test method in pipeline internal steady state

A technology of gas sampling and sampling system, which is applied in the direction of sampling, sampling devices, and analysis materials, etc., to achieve fast response, reduce the cost of transformation and upgrading, and increase accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

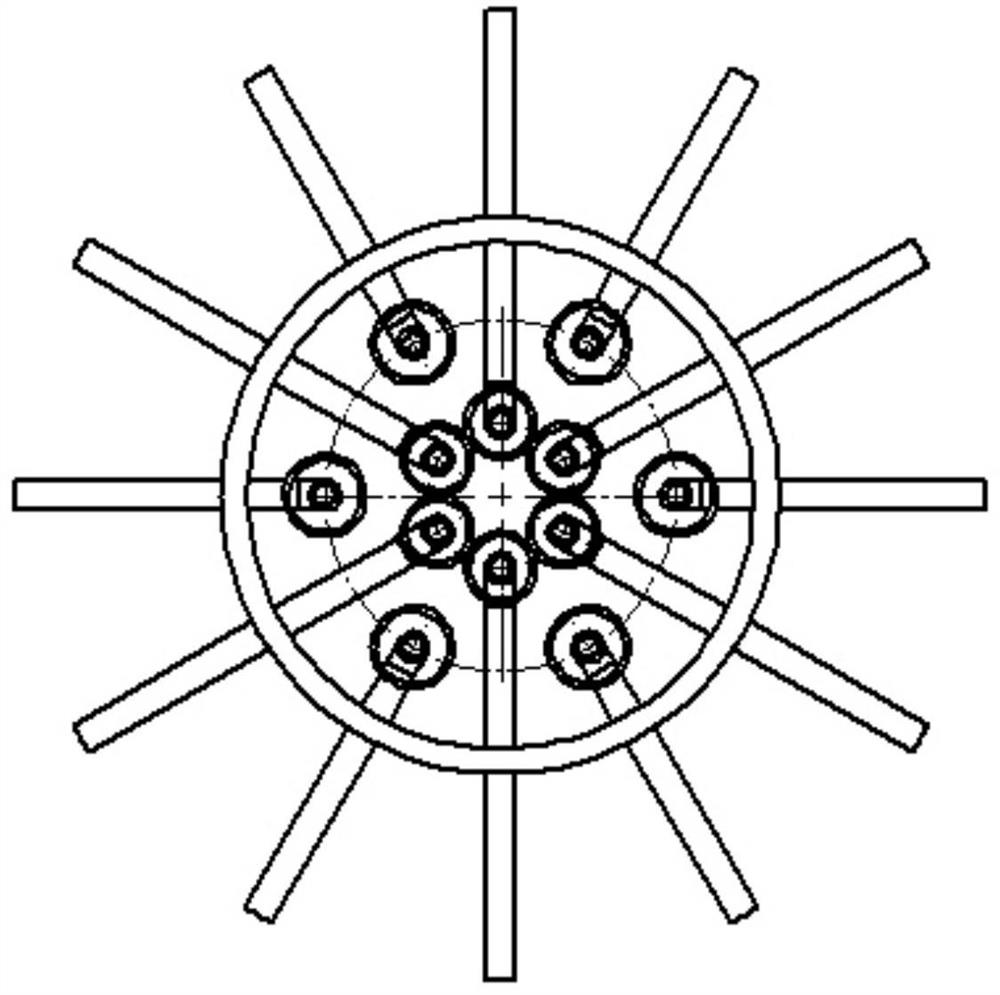

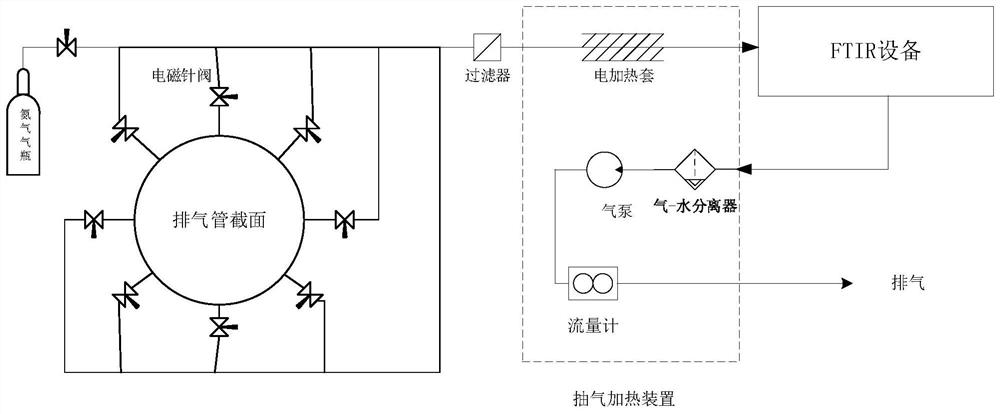

[0042] The invention provides an online multi-point gas sampling and analysis system in a pipeline internal steady state, including a multi-point sampling system, an electromagnetic valve system, an air extraction heating system, and a control system.

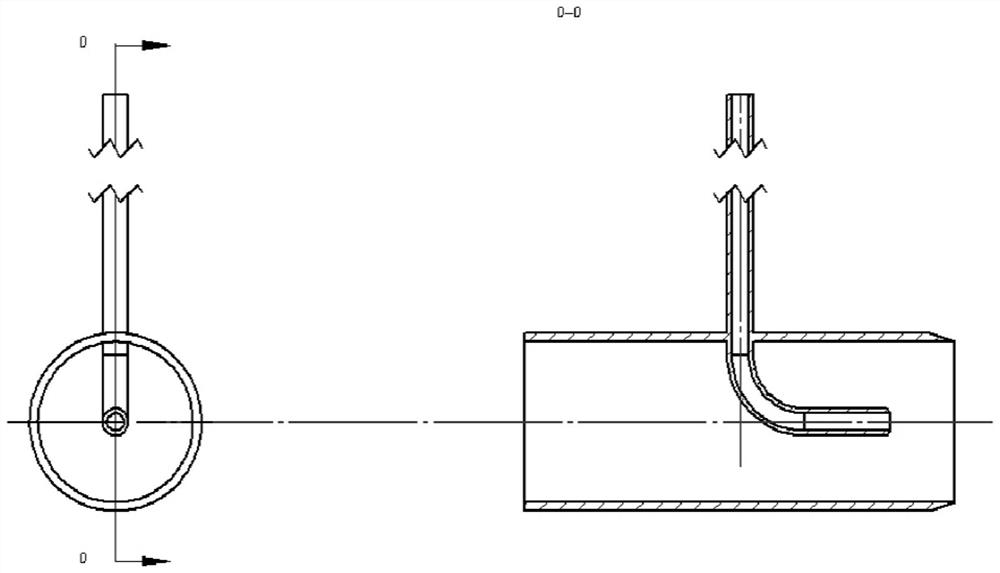

[0043]Multi-point sampling system: mainly refers to the rectification sampling pipe, and also includes the exhaust pipe and the corresponding connection device installed with the rectification sampling pipe. The rectification sampling tube is composed of a rectification cover and a sampling tube. The rectification cover is a short and thick stainless steel tube with an outer diameter of 40mm, a wall thickness of 1mm, and a length of 150mm. The outer ring of the windward side is cut into a slope with an angle of 45°; sampling The tube is a thin and long stainless steel tube. The outer d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com