Parallel suspension multi-downcomer tower plate

A technology of downcomers and trays is applied in the field of parallel suspension multi-downcomer trays, which can solve the problems of increasing the structural complexity of the trays and affecting the uniformity of the flow field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

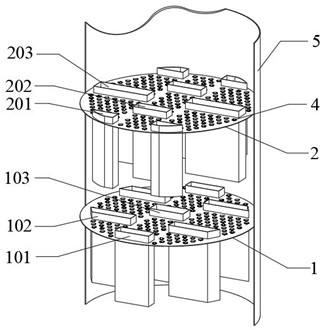

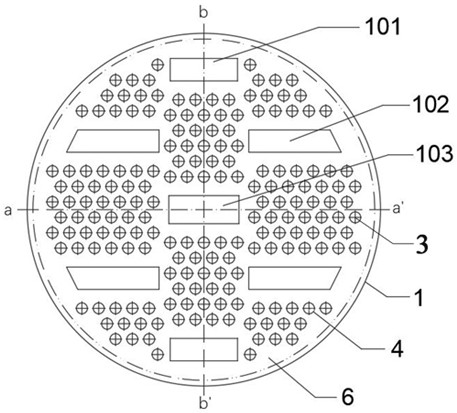

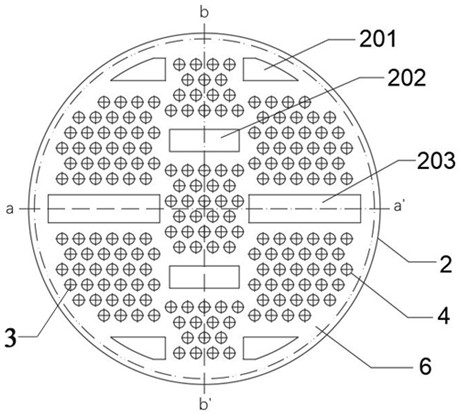

[0034] In a plexiglass tower with a plate spacing of 600mm and a diameter of 1219mm, parallel suspension multi-downcomer trays are installed in the form of "A plate-B plate-A plate-B plate" up and down, and the uppermost layer is a hot water distribution plate , the second layer is the water inlet plate, which is also the primary cold water distribution plate, the third layer is the cold water redistribution plate, and the bottom layer is the test plate; Arranged in an equilateral triangle; the area of the downcomer 101 on the first side is 192cm 2 , the area of the first eccentric downcomer 102 is 248cm 2 , the area of the first central downcomer 103 is 240cm 2 ; The area of the second side downcomer 201 is 60cm 2 , The area of the second eccentric downcomer 202 is 200cm 2 , the area of the second central downcomer 203 is 400cm 2 . The liquid-phase water is used as the operating system. The cold water enters the tower from the water inlet plate through the ce...

Embodiment 2

[0037] In the plexiglass tower with a plate spacing of 600mm and a diameter of 1219mm, install parallel suspension multi-downcomer towers in the form of "A plate-B plate-A plate" and "B plate-A plate-B plate" respectively. The middle tray is a test tray, the lower tray is a gas distribution plate, and the upper tray is a liquid distribution plate; the opening ratio of the trays is 18.96%, and the adjacent solid valves 3 are arranged in a regular triangle; The area of the first downcomer 101 is 192cm 2 , the area of the first eccentric downcomer 102 is 248cm 2 , the area of the first central downcomer 103 is 240cm 2 ; The area of the second side downcomer 201 is 60cm 2 , The area of the second eccentric downcomer 202 is 200cm 2 , the area of the second central downcomer 203 is 400cm 2 , Install a mist collector above the upper tray. With air and water as the operating system, the spray density is 60m 3 / (m 2 h), measure the mist entrainment of A-type tray 1 a...

Embodiment 3

[0040] In the plexiglass tower with a plate spacing of 600mm and a diameter of 1219mm, install parallel suspension multi-downcomer towers in the form of "A plate-B plate-A plate" and "B plate-A plate-B plate" respectively. The middle tray is a test tray, the lower tray is a gas distribution plate, and the upper tray is a liquid distribution plate; the opening ratio of the trays is 18.96%, and the adjacent solid valves 3 are arranged in a regular triangle; The area of the first downcomer 101 is 192cm 2 , the area of the first eccentric downcomer 102 is 248cm 2 , the area of the first central downcomer 103 is 240cm 2 ; The area of the second side downcomer 201 is 60cm 2 , The area of the second eccentric downcomer 202 is 200cm 2 , the area of the second central downcomer 203 is 400cm 2 ; Install a liquid leakage collector below the lower tray. With air and water as the operating system, the spray density is 60m 3 / (m 2 h), measure the leakage rate of the paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com