A battery module with heating function

A battery module and functional technology, applied in the field of battery modules with heating function, can solve the problems of direct contact between aluminum plates and batteries, complex structure of battery modules, and reduction of energy density of modules, so as to solve uneven heating and save External energy and the effect of shortening the heating up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

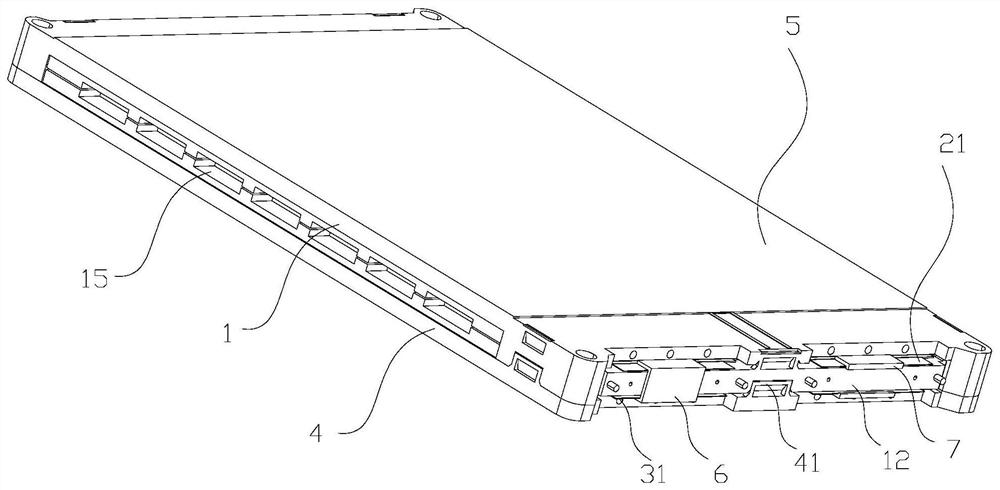

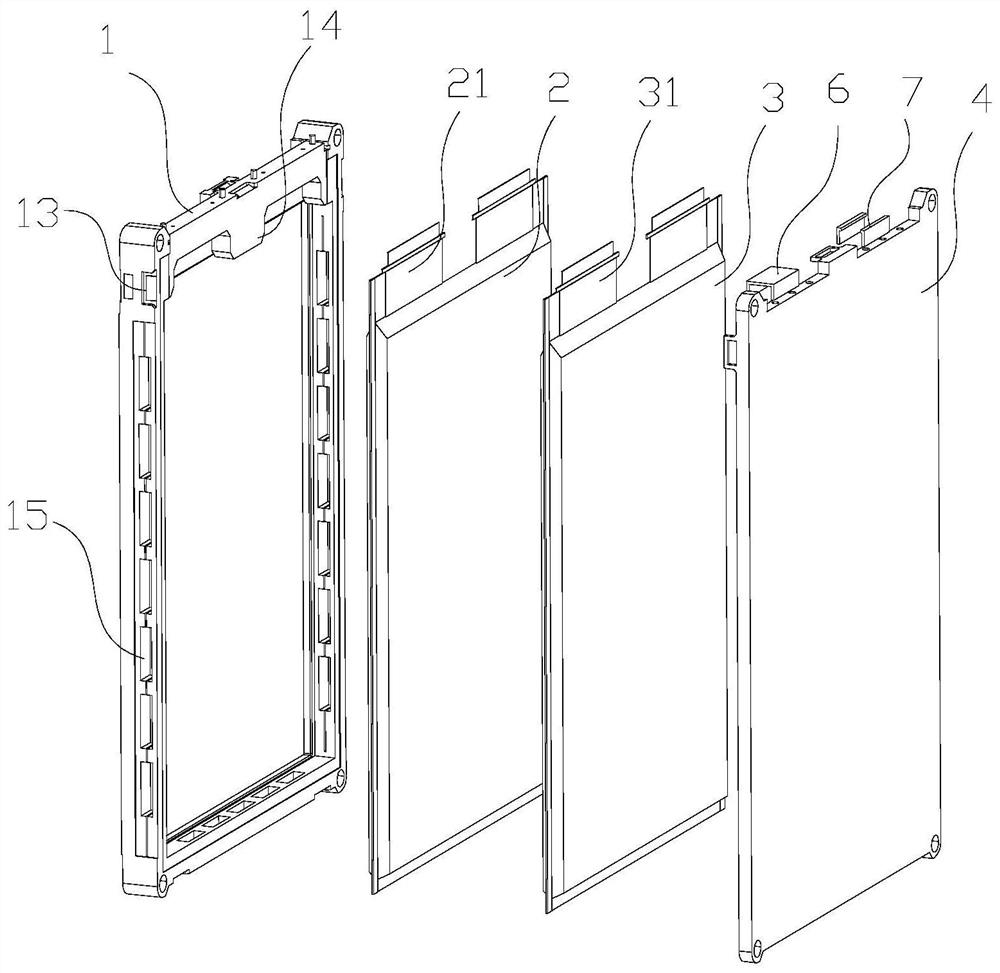

[0038] like Figure 1-4 The shown battery module with heating function includes a casing and a battery arranged inside the casing. In this embodiment, the battery includes a first battery 2 and a second battery 3, both of which are soft-package lithium-ion power batteries. The first battery 2 is provided with two first battery electrodes 21 , and the second battery 3 is provided with two second battery electrodes 31 .

[0039] The shell is provided with an electrode socket 11 , and the battery electrodes of the first battery 2 and the second battery 3 are inserted into the electrode socket 11 . A spacer 12 is provided between the first battery electrode 21 and the second battery electrode 31 to separate the first battery electrode 21 and the second battery electrode 31 . The spacer 12 can be directly arranged on the casing and integrally formed with the casing. A convex body 14 is also provided in the casing for separating the two electrodes of the same battery. There are ...

Embodiment 2

[0046] The difference between this embodiment and the battery module with heating function of Embodiment 1 is that a heating chip is also provided on the outer surface of the lower cover, which can improve the heating efficiency of the battery module. The battery module for the heating function is the same.

Embodiment 3

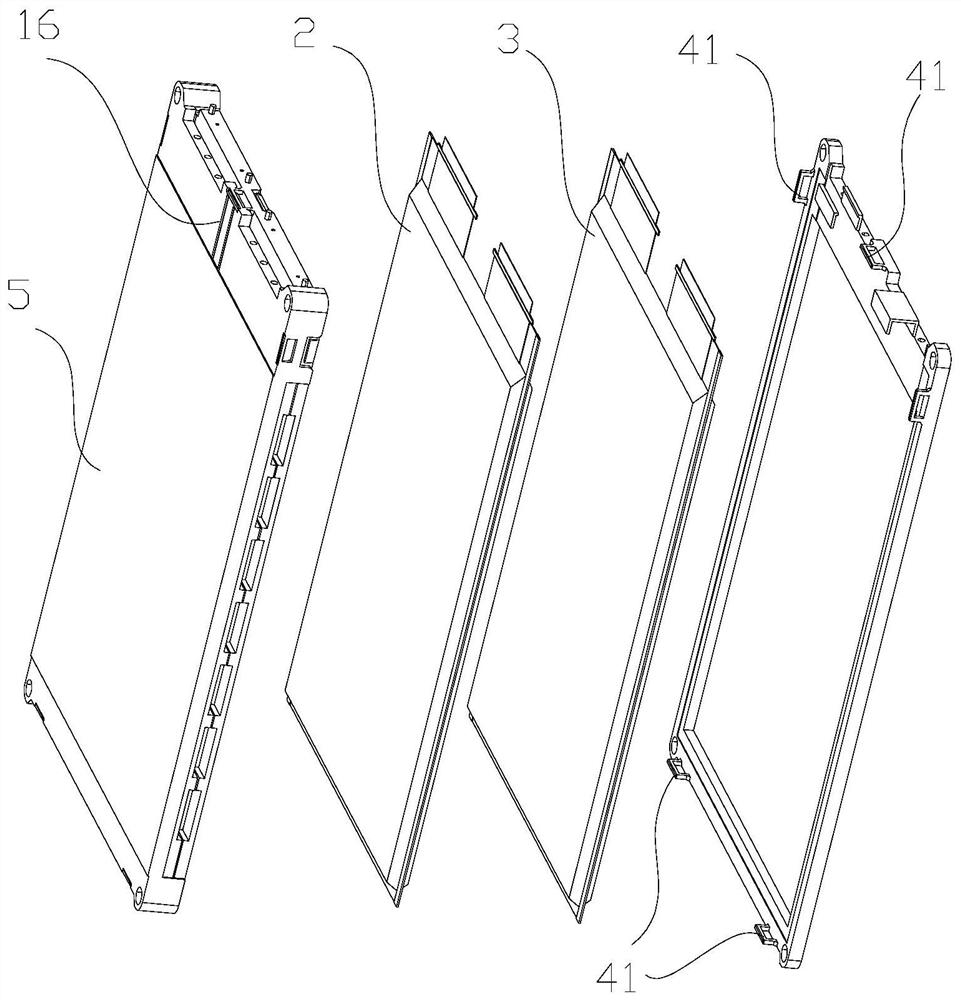

[0048] The difference between this embodiment and the battery module with heating function of Embodiment 2 is that a plurality of batteries are arranged in the casing, the casing is correspondingly provided with a plurality of electrode jacks, and the plurality of batteries are connected in parallel or in series through the conductive sheets connection, and other structures are the same as the battery module with heating function of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com