Vapor chamber, manufacturing method thereof and electronic equipment

A technology of vapor chamber and heat source, which is applied in the structural parts of electrical equipment, electrical components, cooling/ventilation/heating transformation, etc., and can solve the problems of insufficient supply speed of liquid working medium, uneven heat dissipation of vapor chamber, and heat dissipation power Low and other problems, to achieve the effect of preventing dry burning of the hot end, convenient operation, and large capillary suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

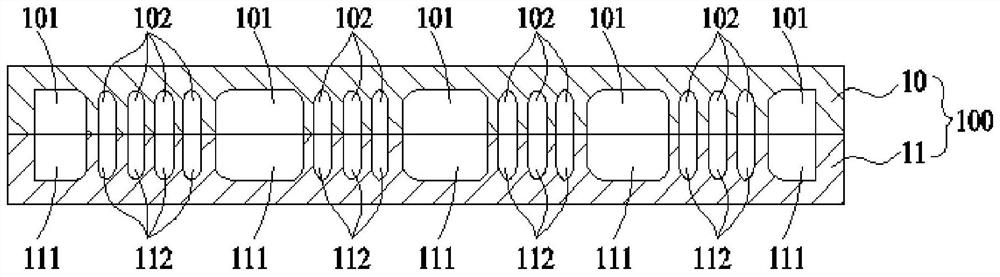

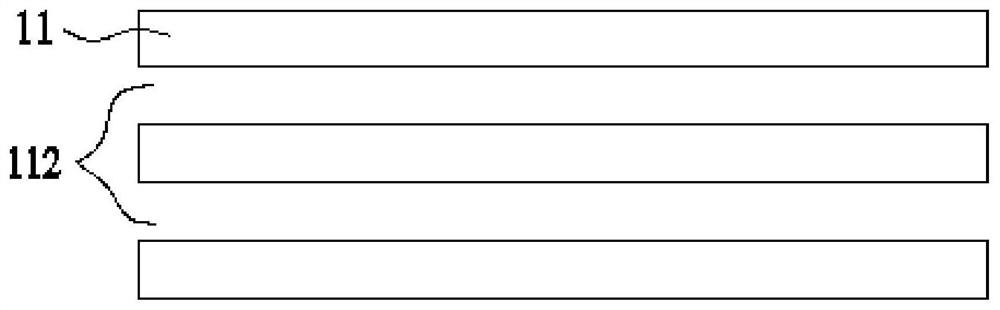

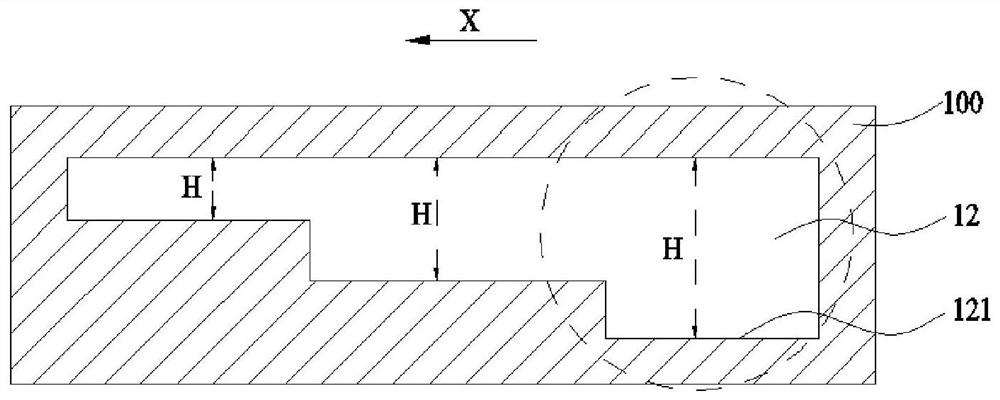

[0083] The embodiment of the present application provides a vapor chamber, which includes a housing 100. A capillary channel 12 is formed in the housing 100. The cross-sectional structure of the capillary channel 12 is as follows: image 3 as shown, image 3 Shown is a schematic diagram of the cross-sectional structure of the capillary channel 12 along its length direction, image 3 The dotted line at the middle right end shows the area close to the heat source, and the left end is the cooling end. It can be seen that the depth of the capillary channel 12 is deeper as it is closer to the heat source, and shallower as it is closer to the cooling end. image 3 In the X direction, the depth H of the capillary channel 12 gradually becomes shallower. Thus, the deeper region of the capillary channel 12 (i.e. image 3 The area at the middle right end) has a larger space and can store more liquid working fluid, while the shallower area has a smaller space and can store less liquid w...

Embodiment 2

[0091] Such as Figure 5 As shown, in the vapor chamber provided in this embodiment, the multiple capillary channels 12 are arranged in a parallel linear manner, and the multiple parallel capillary channels 12 all extend along the first direction X, and the distance between two adjacent capillary channels 12 is The space is separated by a partition rib 13, and at least one gap 131 is provided on the partition rib, and the gap 131 can communicate with two adjacent capillary channels 12. Replenishing, so that the flow of the liquid working medium is more uniform, and preventing the flow of the liquid working medium in part of the capillary channel 12 from breaking.

[0092] Due to the existence of the gap 131, a complete separating rib 13 can be separated into multiple sections separating ribs 132, such as Figure 5 As shown, the length of a section of dividing rib 132 along the first direction is b, and the width is a, and the value of a:b can be set from near the heat source ...

Embodiment 3

[0106] Such as Figure 8 , Figure 9 As shown, in the vapor chamber provided in this embodiment, the plurality of capillary channels 12' are distributed in a divergent manner, that is, the plurality of capillary channels 12' are distributed in the circumferential direction around the same center, and the plurality of capillary channels 12' extension cords pass through the center. Wherein, two adjacent capillary passages 12' are separated by radially arranged partition ribs 13', and a plurality of capillary passages 12' communicate in the circumferential direction through at least one annular passage 14, and the center of circle of the annular passage 14 is connected to the center. Coincidence, when installing, the center can be set close to the heat source. The above-mentioned annular channel 14 enables the liquid working fluid in the adjacent capillary channels 12' to replenish each other through the annular channel 14, thereby making the flow of the liquid working medium m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com