Building wall pipeline laying grooving equipment

A slotting equipment and construction technology, applied in stone processing equipment, stone processing tools, work accessories, etc., can solve the problem of affecting the health of workers in the use environment, the slotting machine does not have a dust suction device, and affects the aesthetic effect of pipe slots, etc. problems, to achieve the effect of ensuring the use environment and physical health, improving the scope of application and flexibility, and facilitating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

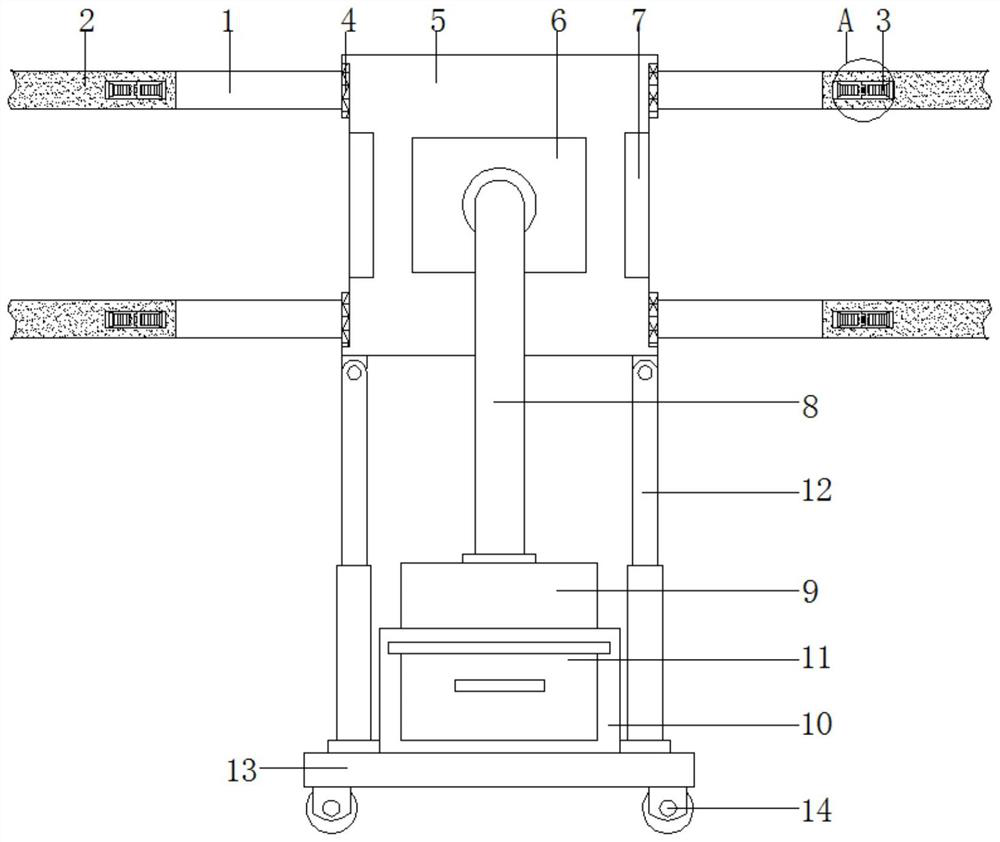

[0029] see Figure 1-2 , a wall pipe laying slotting equipment for construction, comprising a first plate body 1 and a second plate body 2, the first plate body 1 is provided with two groups, and placed in parallel, the outer wall of the first plate body 1 is slidably connected with a sliding Block 4, the outer wall of slide block 4 is fixedly connected with moving plate 5, and the middle interior of moving plate 5 is fixedly installed with slotting machine 6, and the outer wall of slotting machine 6 is fixedly installed with telescopic pipe 8, and one end of telescopic pipe 8 is fixedly installed with The vacuum cleaner 9 has a box body 10 fixedly installed under the vacuum cleaner 9 , and a material storage box 11 is clamped inside the box body 10 ; a bottom plate 13 is fixedly connected to the bottom of the box body 10 . The left and right ends above the bottom plate 13 are fixedly equipped with telescopic rods 12 , and the top of the telescopic rods 12 is flexibly connecte...

Embodiment 2

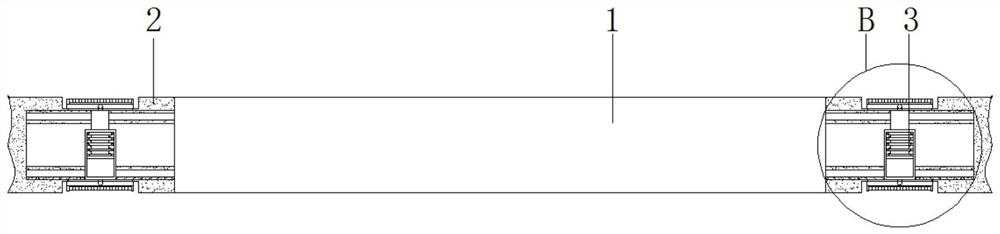

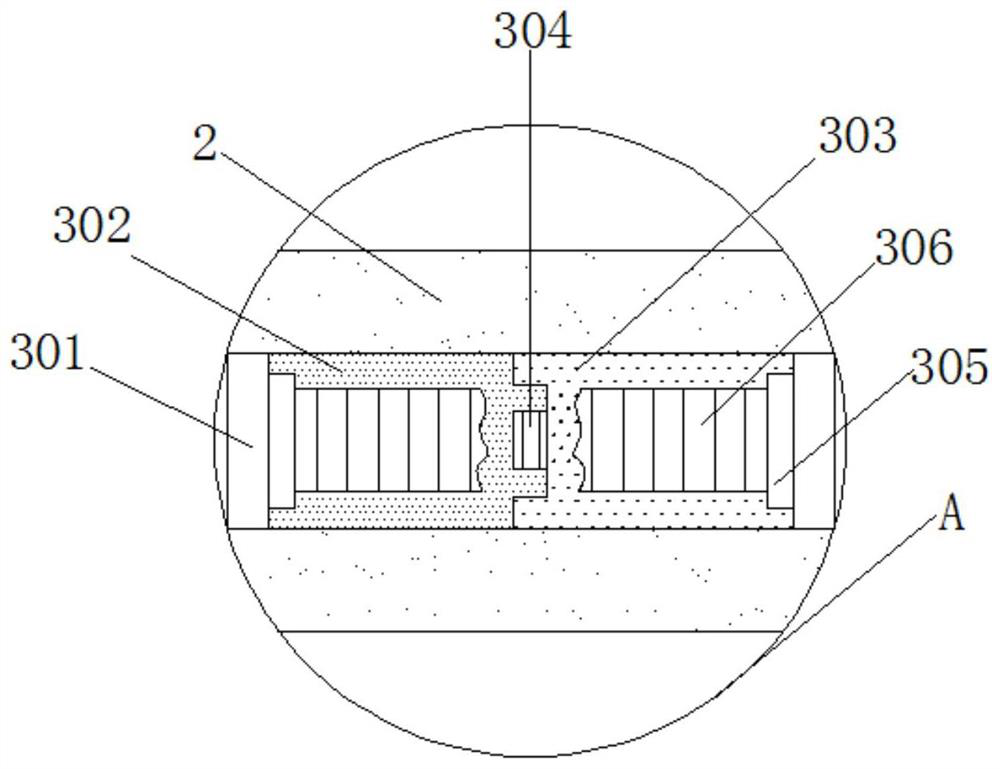

[0033] see Figure 1-5, the building uses wall pipe laying slotting equipment, the left and right sides of the first plate body 1 are clamped with the second plate body 2, and a clamping mechanism 3 is arranged between the first plate body 1 and the second plate body 2, and the clamping The connecting mechanism 3 includes a card slot 301, a first clamping plate 302, a second clamping plate 303, a rotating shaft 304, a connecting plate 305, a first spring 306, a connecting shaft 307, a guide rod 308, a sleeve 309, a second spring 310 and a limiter. Position plate 311; the inside of the second plate body 2 is provided with a card slot 301, the inside of the card slot 301 is provided with a first card plate 302 and a second card plate 303, the first card plate 302 and the second card plate 303 One end is connected by being provided with a rotating shaft 304; the other end of the first clamping plate 302 and the second clamping plate 303 are fixedly connected with a connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com