Manufacturing method of metal hand mold

A manufacturing method and hand mold technology, applied in metal processing equipment, coating, etc., can solve the problems of the same accuracy and low repeat similarity, high production cost and environmental protection cost, and scrapped models have no recycling value, so as to facilitate polishing and polishing , improve production quality, and improve energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. The following description is only exemplary and does not limit the protection scope of the invention.

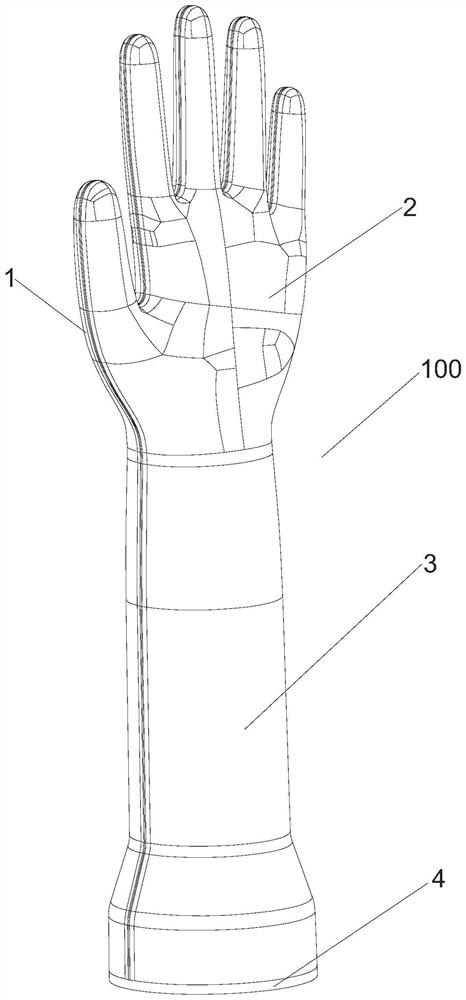

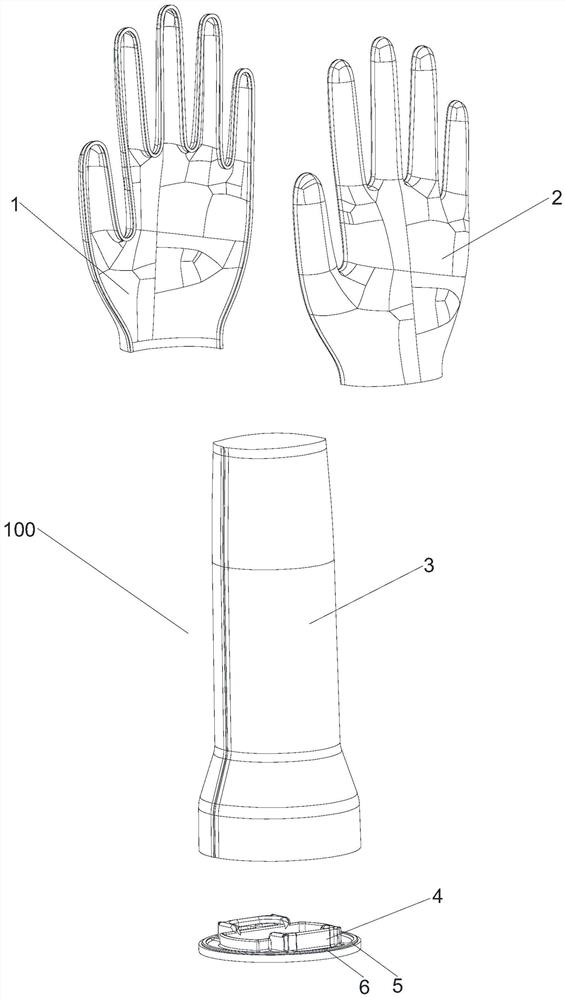

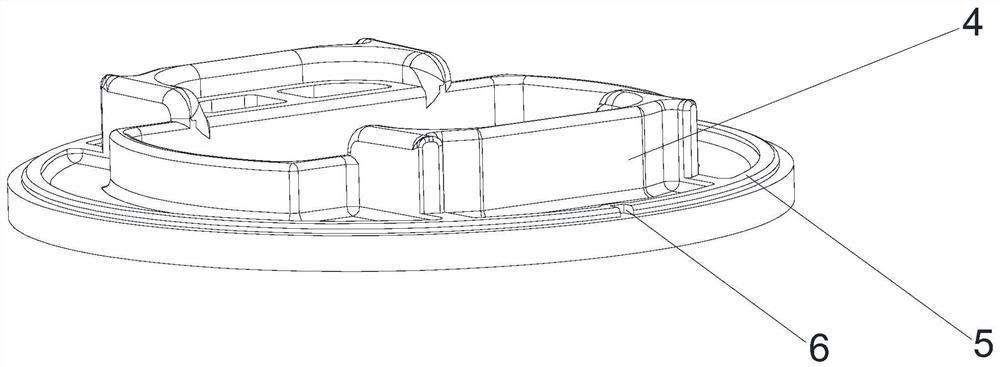

[0035] Such as Figure 1-Figure 3 Shown, a kind of manufacturing method of metal hand mold comprises the following steps:

[0036] (1) Press the metal plate to form the left palm blank 1 and the right palm blank 2. Of course, it is necessary to use the corresponding mold to form the left palm blank 1 and the right palm blank 2; the left palm blank 1 and the right palm blank 2 After heating, use a forging machine to forge the left palm blank 1 and the right palm blank 2; then trim the left palm blank 1 and the right palm blank 2 and then deburr and clean them; of course, the left palm blank 1 also needs to be Drying with the right palm blank 2;

[0037] (2) After the metal pipe is made of the special-shaped pipe using the expansion and contraction ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com