Driving device for injection molding machine and injection molding system thereof

A driving device and injection molding machine technology, applied in the field of injection molding machines, can solve problems such as difficult ejection of injection molding products, unsuitable injection molding products, and low stroke precision, and achieve the effects of rapid change, wide application range, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

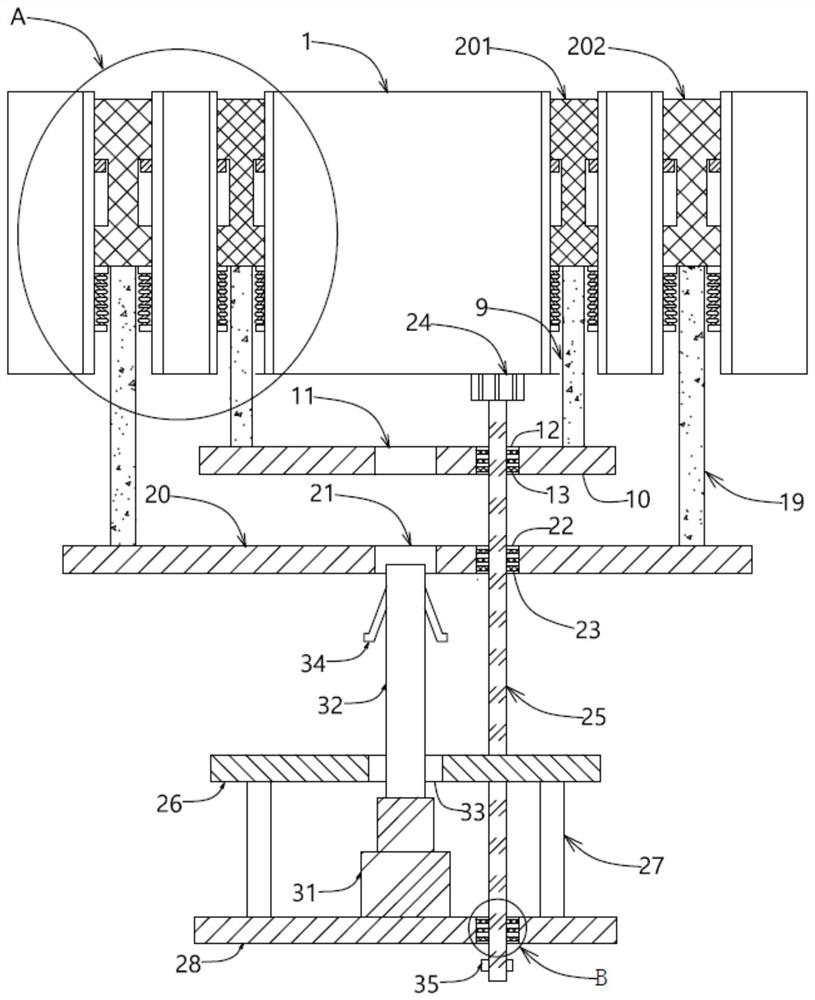

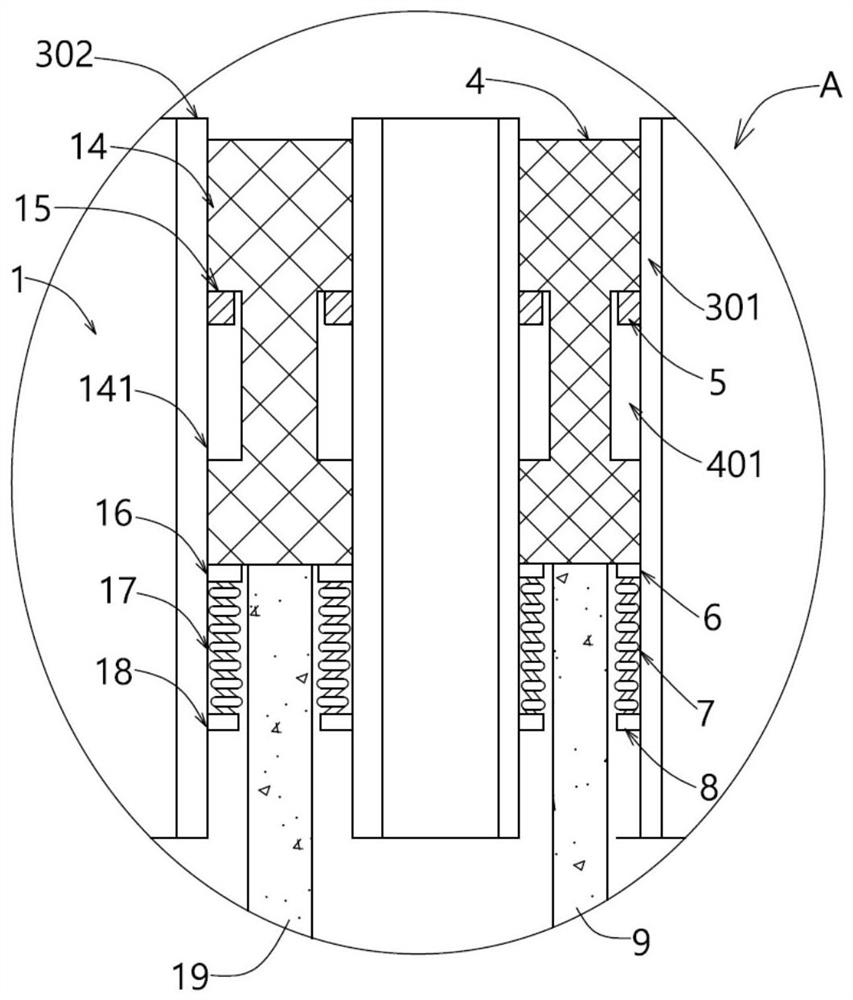

[0046] Embodiment 1: When in use, the movable mold of the injection mold can be fixed on the mounting plate 1. After the injection mold completes the molding process of the injection molded product, it needs to drive the ejector mechanism to eject the injection molded product. At this time, for larger sizes 1. For the injection molding product whose inner hole position of the convex column does not overlap with the second installation groove 202, if the product has lower requirements on machining accuracy, the oil cylinder 31 can be activated, and the oil cylinder 31 will quickly push the drive rod 32 to Move outward, so that the elastic clamping part 34 is inserted into the second clamping hole 21 on the second push plate 20, under the restriction of the second clamping hole 21, due to the second spring 17 compared with the elastic clamping part 34 is more likely to be deformed, so the second push plate 20 is first pushed out outwards, and the second push plate 20 at this time...

Embodiment 2

[0047] Embodiment 2: When in use, the movable mold of the injection mold can be fixed on the mounting plate 1. After the injection mold completes the molding process of the injection molded product, it needs to drive the ejector mechanism to eject the injection molded product. At this time, for smaller size 1. For the injection molding product whose inner hole position of the convex column does not overlap with the first installation groove 201, if the product has lower requirements on machining accuracy, the oil cylinder 31 can still be activated, and the oil cylinder 31 will quickly push the drive rod 32 Move outwards so that the elastic clamping part 34 is engaged in the second engaging hole 21 on the second push plate 20. Under the restriction of the second engaging hole 21, the second spring 17 is more elastically engaged than the second spring 17. Part 34 is more likely to be deformed, and the second push plate 20 is first pushed out outwards. At this time, the second pus...

Embodiment 3

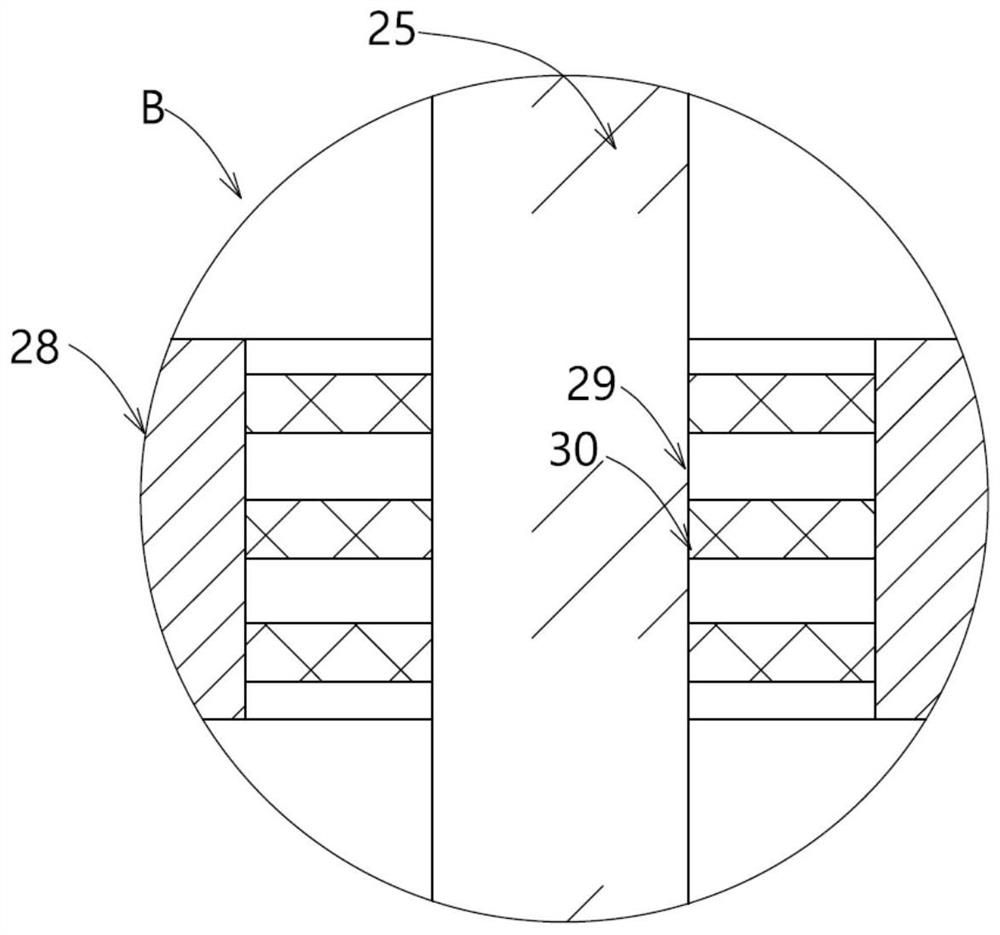

[0048] Embodiment 3: When in use, the movable mold of the injection mold can be fixed on the mounting plate 1. After the injection mold completes the molding process of the injection molded product, it needs to drive the ejector mechanism to eject the injection molded product. At this time, for larger sizes 1. For the injection molding product whose inner hole position of the convex column does not overlap with the second installation groove 202, if the product has higher requirements on machining accuracy, the driving motor 24 can be started, and the driving motor 24 drives the screw 25 to rotate , so that the nut 26 moves slowly along the lead screw 25 to carry out the refined movement of the displacement. The nut 26 drives the base plate 28 to gradually approach the mounting plate 1 through the connecting rod 27, and then the base plate 28 drives the drive rod 32 through the oil cylinder 31, so that The elastic retaining member 34 is engaged in the second engaging hole 21 on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap