Assembly type composite energy dissipation shear wall

A shear wall and prefabricated technology, applied to walls, protective buildings/shelters, buildings, etc., can solve the problems of inconvenient maintenance of energy-consuming devices, increased structural weight, and difficult replacement, and achieve daily maintenance It is convenient and simple, the construction time is short, and the effect of improving ductility and energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

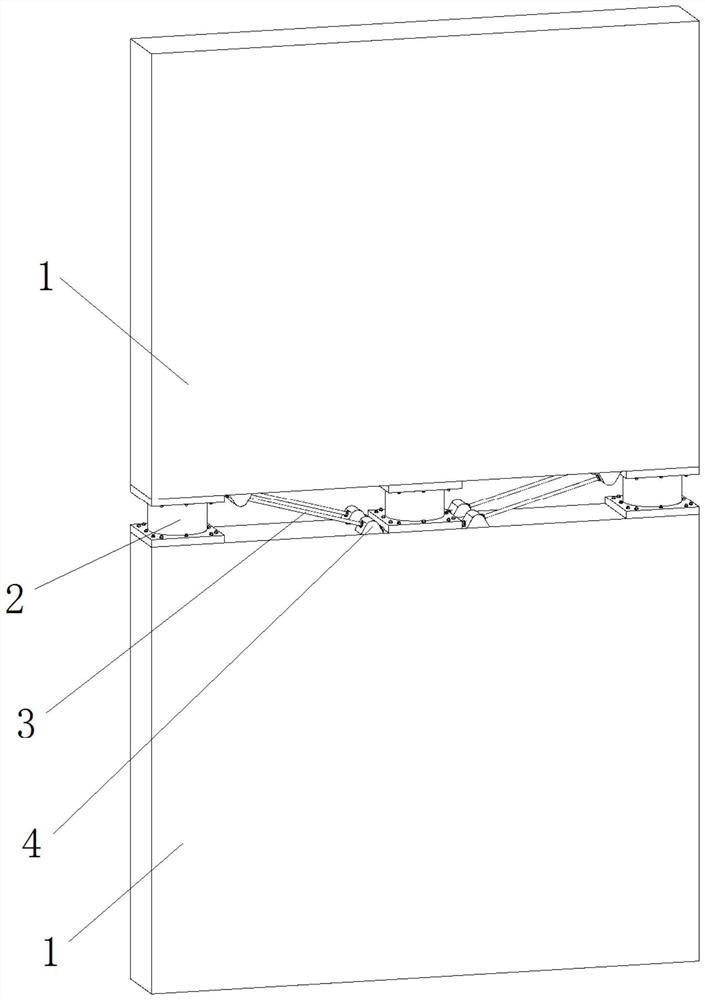

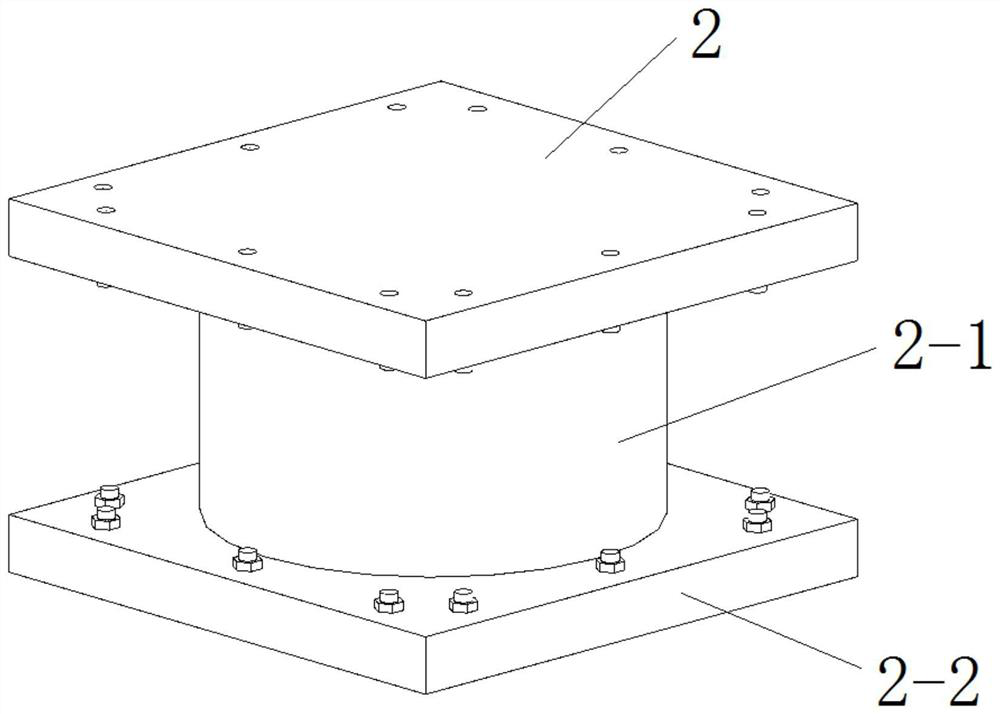

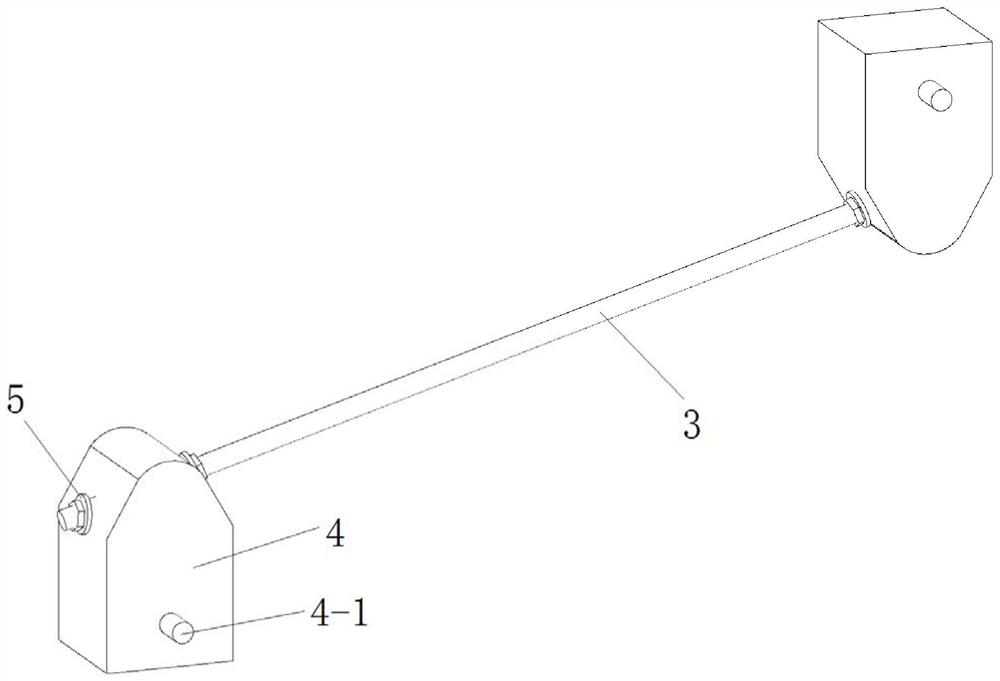

[0021] like figure 1 As shown, a prefabricated composite energy-dissipating shear wall includes two shear wall members, and multiple seismic isolation supports are evenly arranged between the two shear wall members. One end of the seismic isolation support is connected with a shear force Wall component connection, the other end of the seismic isolation support is connected to another shear wall component, at least one shape memory alloy rod is arranged between two adjacent seismic isolation support, and one end of the shape memory alloy rod passes through the rod The piece connector is connected with one shear wall member, and the other end of the shape memory alloy member is connected with another shear wall member through the member connector, and the shape memory alloy member between the two shear wall members is corrugated distributed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com