[0003]In the existing technology,

drilling and blasting or static fracturing technology is usually used to pre-crack the hard rock faults in the coal mining face, so as to improve the

rock breaking efficiency of coal cutters. The patent publication number is CN105387775A, and the patent titled "a method and device for

processing faults in fully mechanized mining face" proposes a method for pre-splitting hard rock faults by

drilling and blasting at the position of the coal mining face. It is CN105587319A, the patent and the patent publication number of " a kind of method of quickly breaking the roof strata over the fault in the fully mechanized mining face with large mining height " is CN110186340A, and the patent proposed by the name " the method for smoothly advancing when the fully mechanized mining face encounters a fault " A method of pre-splitting the hard rock faults of the coal mining face by

drilling and blasting in the pre-excavation auxiliary roadway is proposed. The following deficiencies exist in using the drilling and blasting method to pre-split the hard rock faults of the working face: 1) Blasting in high-gas mines has the following disadvantages: Potential safety hazards; 2)

Coal mines in Northwest China have strict control over

pyrotechnics, and lack of sufficient explosives for blasting pre-splitting of hard rock faults; 3) When blasting pre-splitting is carried out at the coal mining face, the rock fragments produced are Under the action of the blasting

shock wave, it may cause damage to the working face equipment, such as hydraulic supports; 4) When drilling and blasting in the auxiliary roadway of pre-excavation, the excavation volume of the coal mine roadway is increased, and the cost of coal mining per

ton is increased. Guiliang The paper titled "Application of Static Fracturing Technology in Fully Mechanized Mining Faults" published by Yu proposed a method of treating hard rock faults in the working face through static fracturing technology. The large-

diameter borehole is used as a

free space for static fracturing, and a number of charging holes are excavated around it; then the static fracturing agent is poured into the charging hole, and after the agent is fully reacted, the broken rock mass is removed with a pneumatic pick to form a larger

Free space; Finally, excavate several caving holes around the charging hole again, pour static fracturing agent for secondary

rock breaking, and assist the coal cutter to

cut hard rock faults. This method has the following disadvantages: 1) The whole fracturing process It can only be carried out at the position of the coal mining face with low surrounding rock stress, and it is impossible to pre-split the fault rock mass at the advanced working face with high surrounding rock stress, which will affect the normal production of the working face;

[0004]2) The drilling process is complex, requiring the use of drilling rigs to

drill large-

diameter holes and pneumatic drills (or cable drills) to dig charging holes and caving holes; 3)

Rock breaking The process is cumbersome, and it is necessary to complete two static rock breaking (static fracturing in the charging hole and the caving hole respectively); 4) It takes about 12 hours to complete one fracturing (reaction time of the fracturing agent), and the coal cutter cuts Before, it was necessary to use a pneumatic pick to remove part of the broken rock mass, which increased labor costs and time costs; 5) Static breaking agents were non-recyclable

consumables, which increased the economic cost of rock breaking. In summary, in the field of underground coal mining , there is an urgent need for a low-cost, high-efficiency, and safe method for dealing with hard rock faults in coal mining face

[0005]

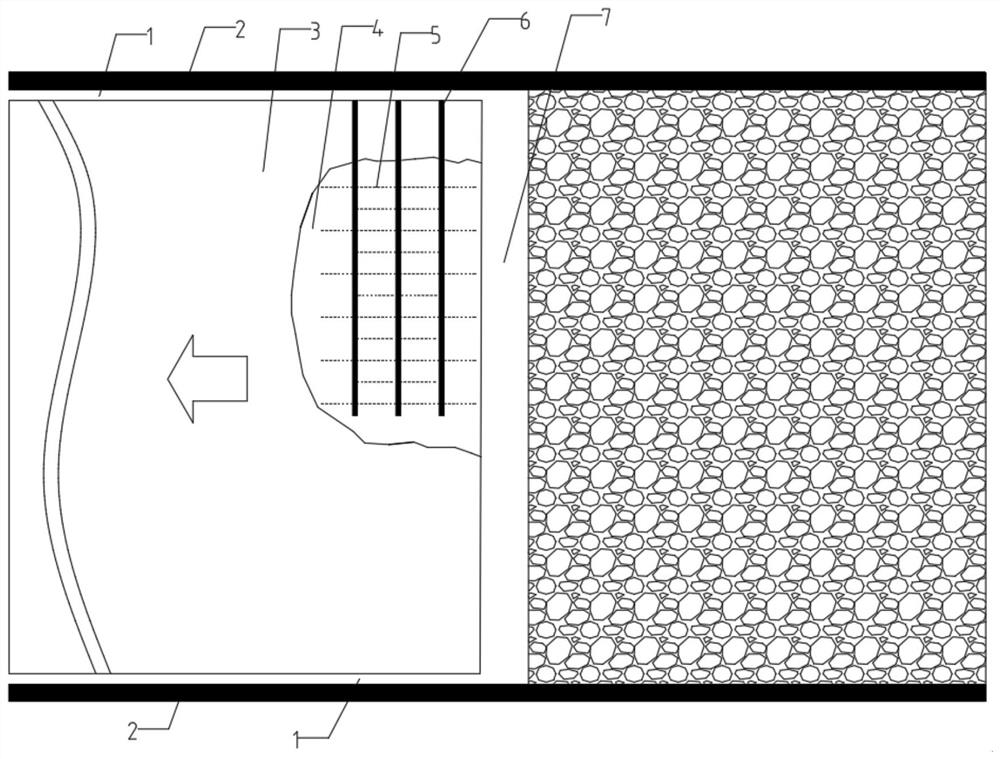

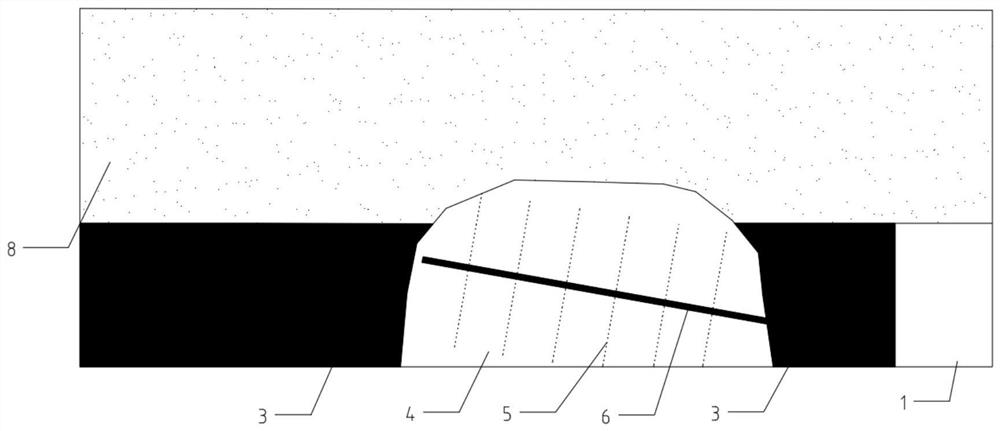

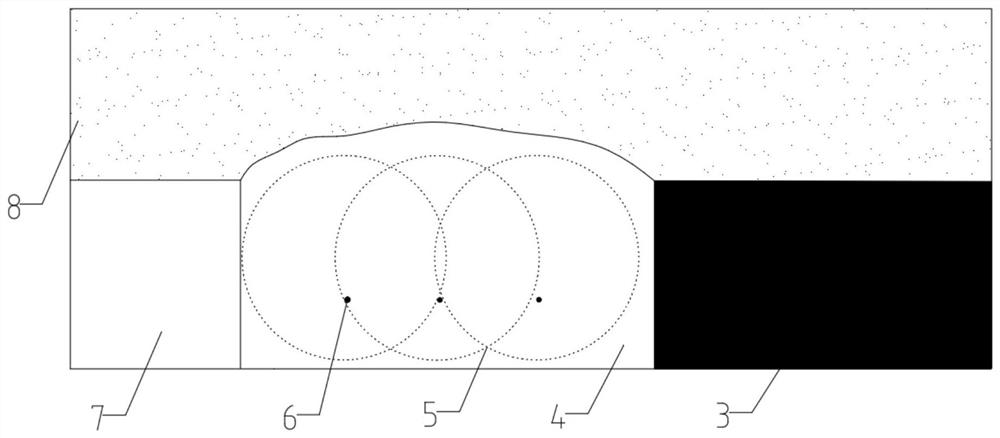

Hydraulic fracturing technology originated in the field of oil exploitation. It creates artificial fractures by injecting high-pressure water into the rock mass of the reservoir to improve the permeability of the reservoir. At present, This technology is widely used in the field of underground coal mine mining, including coal seam gas permeability enhancement, hard roof

impact rock pressure prevention and control of working face, roof cutting and pressure relief beside roadway of mining roadway, roof treatment of triangular area of working face and rapid tunneling of roadway, etc. The research and application of the hard rock fault in the coal working face is still blank. Aiming at the above-mentioned problems in the prior art in the treatment of the hard rock fault in the coal mining face, the present invention proposes a rapid hydraulic fracturing process for the coal mining face in the coal mine. Hard Rock Fragmentation Method

Login to View More

Login to View More  Login to View More

Login to View More