High-voltage transformer for TV. receiver

A technology of high-voltage transformers and television receivers, which is applied in the field of high-voltage transformers, can solve the problems of high cost, and achieve the effects of capacity improvement, cost reduction, and good transformer coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

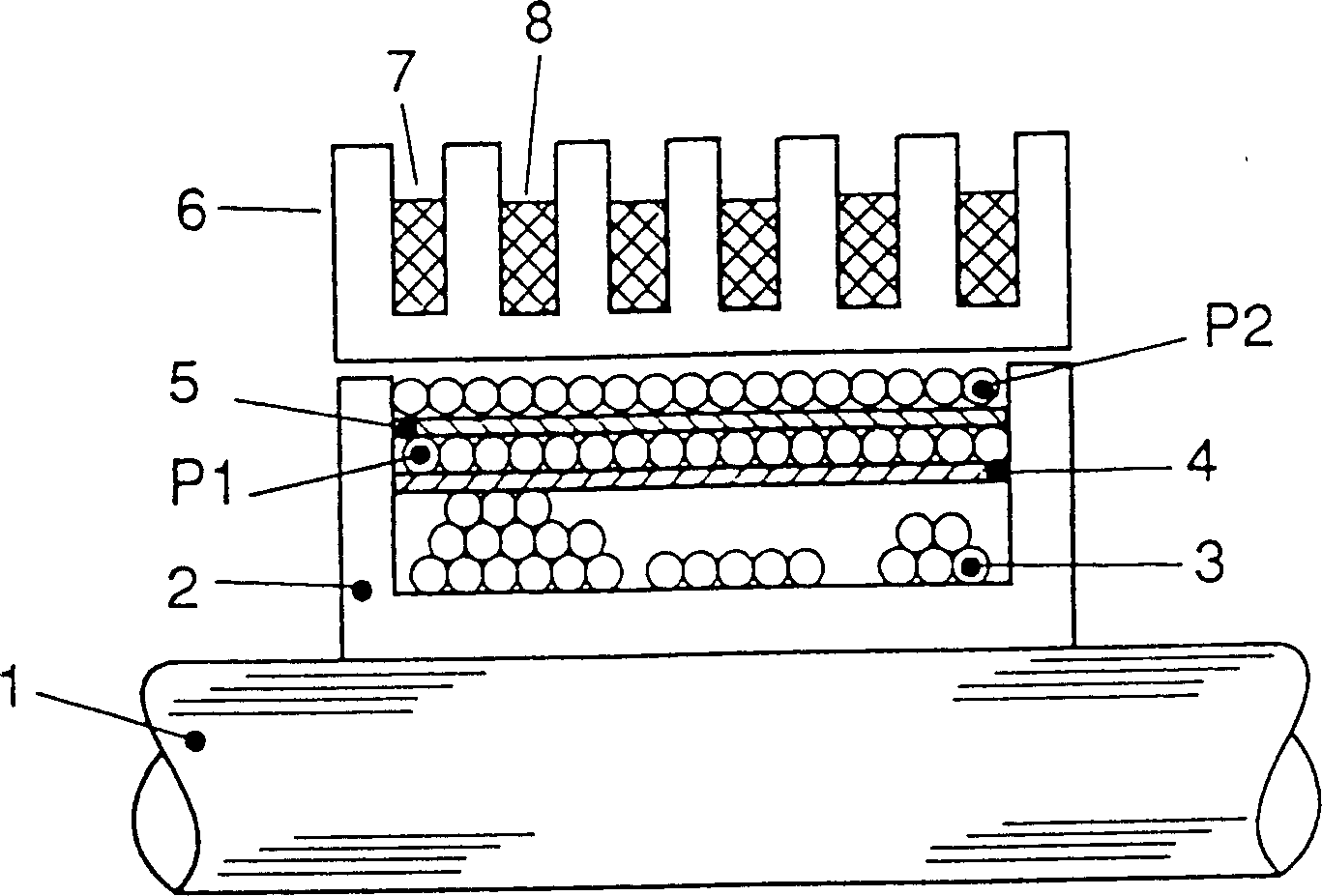

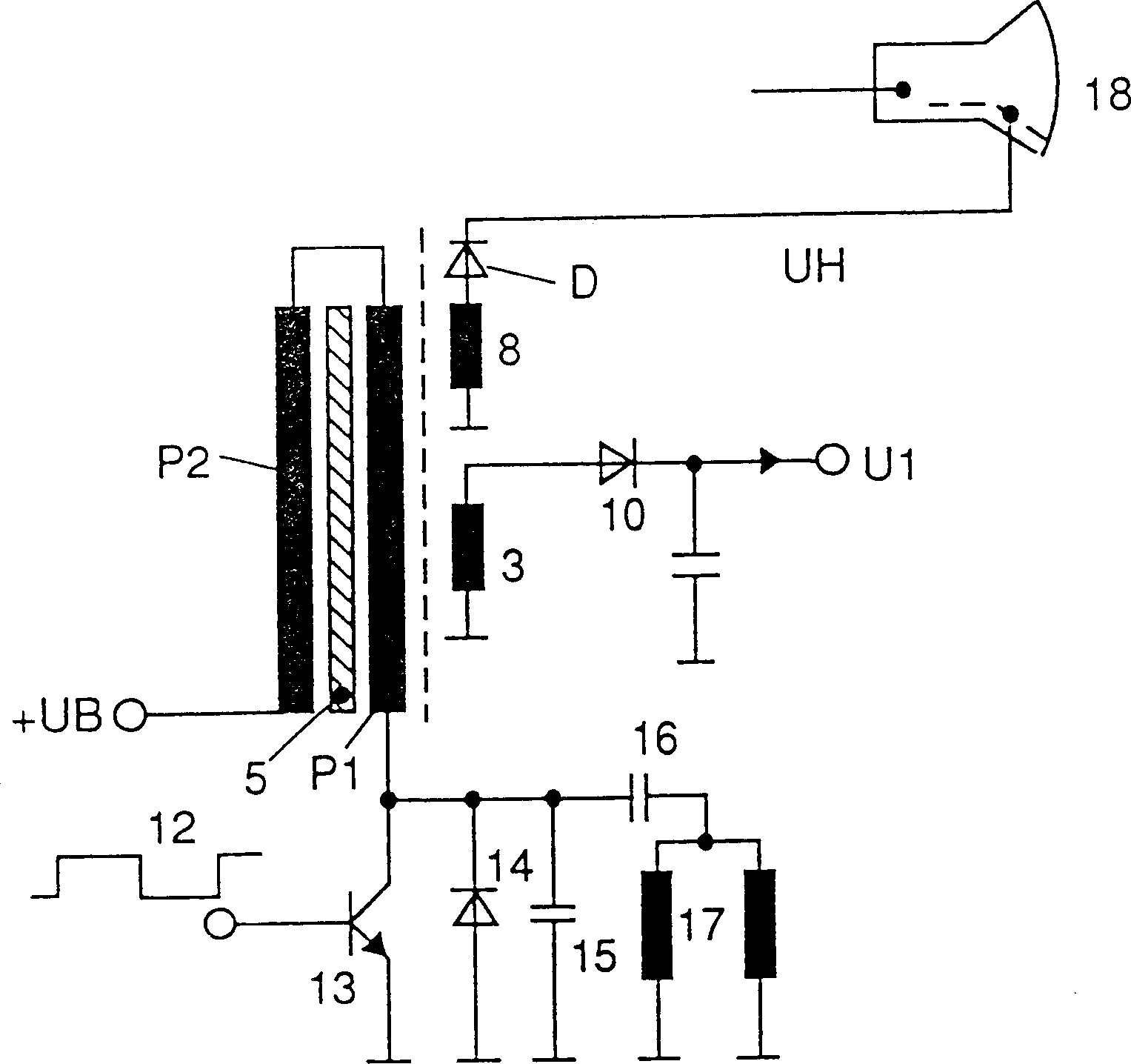

[0016] figure 1 Shown is a core leg 1 of a high voltage transformer core. The core is preferably designed as a U / U core, E / I core or U / I core. The coil former 2 is placed on the core leg 1 . First, located at the bottom of the bobbin 2 are a plurality of auxiliary windings 3, which are used, for example, to generate operating voltage, pulse voltage, or heating of the picture tube. The auxiliary winding 3 has an uneven surface. For this reason, a bushing 4 made of a dielectric material and having a wall thickness of eg 0.4 to 0.8 mm is placed on the auxiliary winding 3 , which bushing forms a smooth bottom layer of the primary winding. The first element P1 of the primary winding is first placed on the bushing 4 in the form of a coil layer. The winding unit P1 is wound in a bifilar manner with a double enamelled copper wire (CuEE) having a diameter of 2×0.45 mm. Another bushing 5 is placed on the winding unit P1. The second element P2 of the primary winding connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com