Fiber bragg grating packaging structure and packaging method

A fiber grating and packaging structure technology, applied in the directions of grating fiber, cladding fiber, optical waveguide light guide, etc., can solve the problems of complex packaging process and inability to adjust the stress of fiber grating, so as to reduce the use cost, process difficulty and manufacturing cost. , to achieve the effect of adjustable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

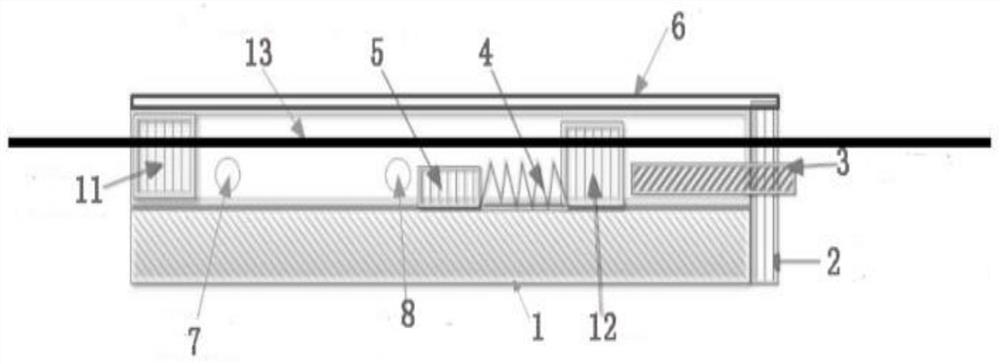

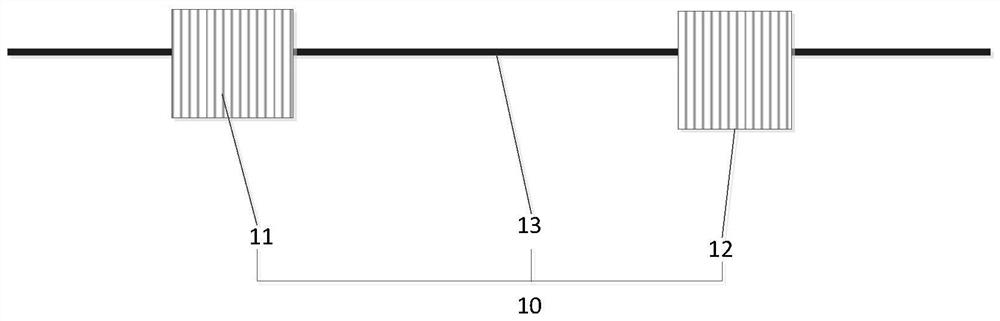

[0068] refer to figure 1 with figure 2 , the present invention provides a fiber grating packaging structure, including a housing 1, and also includes,

[0069] The fiber grating assembly 10 includes a fixed slider 11, a moving slider 12 and a fiber grating 13, the fixed slider 11 is fixedly connected to one end of the housing 1; the fixed slider 11 and the moving slider 12 Each is provided with an optical fiber installation groove (not shown in the figure), and the fiber grating 13 is respectively fixedly connected to the fixed slider 11 and the movable slider 12 through the optical fiber installation groove;

[0070] A spring 4, the spring 4 is connected with one end of the moving slider 12;

[0071] A differential screw 3 and a fixed frame 2, one end of the differential screw 3 is threadedly connected to the fixed frame 2, the other end of the differential screw 3 is connected to the other end of the movable slider 12, and the fixed frame 2 is connected to At the other e...

Embodiment 2

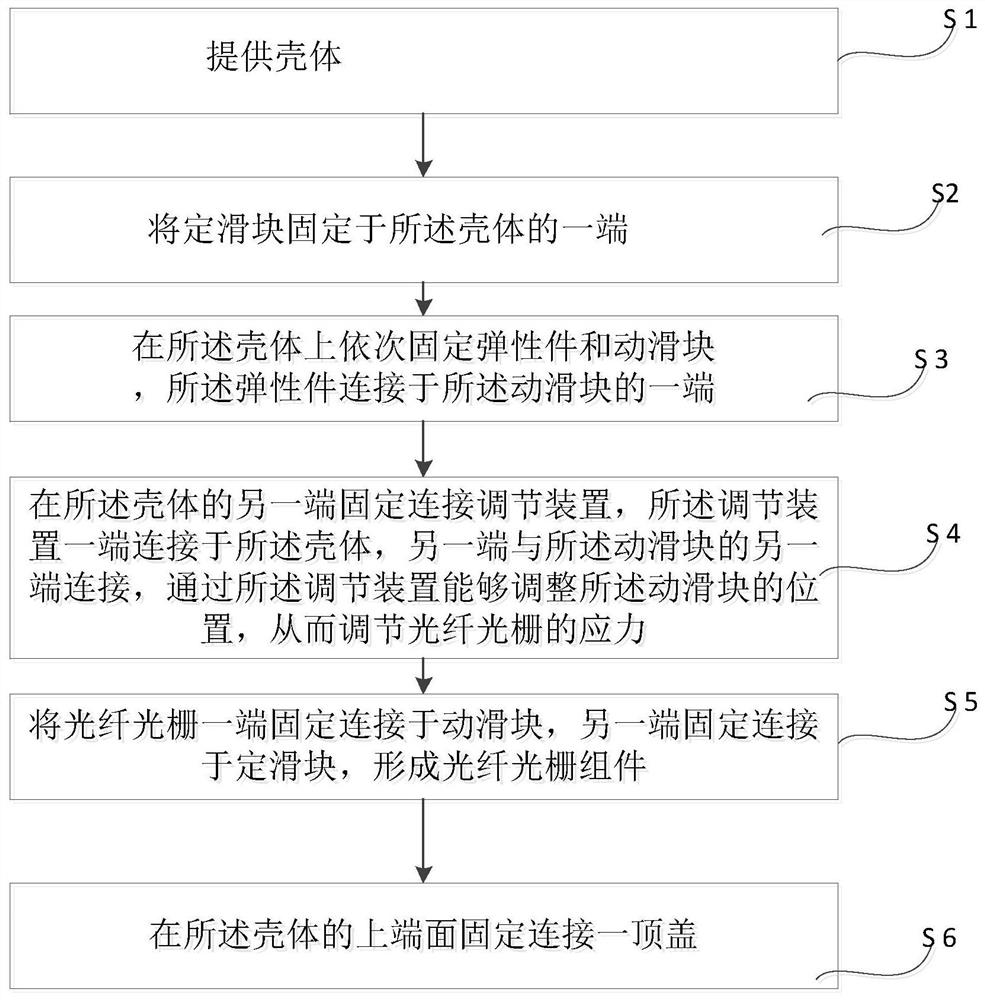

[0079] refer to image 3 , the present invention also provides a fiber grating packaging method for preparing the packaging structure of the fiber grating 13 as described in embodiment 1, comprising:

[0080] S1: providing housing 1;

[0081] S2: fixing the fixed slider 11 to one end of the housing 1;

[0082] S3: fixing the spring 4 and the moving slider 12 sequentially on the housing 1, the spring 4 is connected to one end of the moving slider 12;

[0083] S4: Fix the fixing frame 2 with the differential screw 3 at the other end of the housing 1, one end of the differential screw 3 is connected with the fixed frame 2, and the other end is connected with the other end of the moving slider 12, by adjusting the differential The screw 3 adjusts the stretching degree of the spring 4 to change the position of the movable slider 12, so that the tension degree of the fiber grating 13 connected between the movable slider 12 and the fixed slider 11 can be adjusted, and the stress of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com