Battery module

A technology for battery modules and battery packs, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as large numbers and complicated process assembly, and achieve the effects of simplifying assembly processes, reducing costs, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

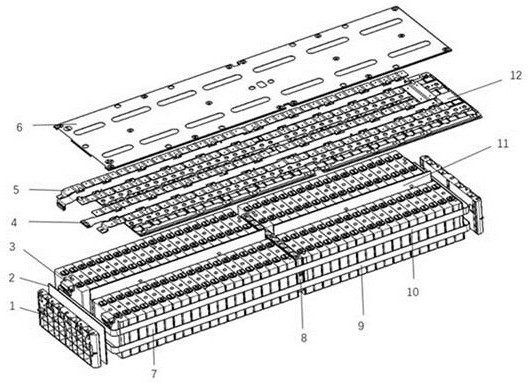

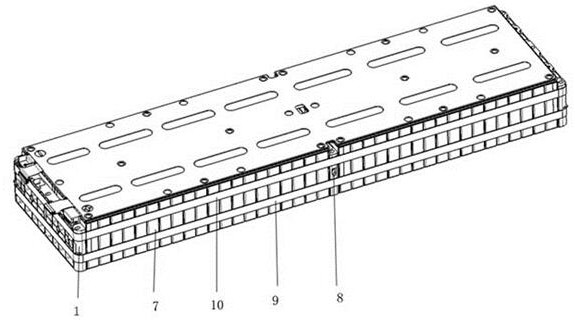

[0022] Embodiment 1: a battery module, such as figure 1 and figure 2 As shown, it includes battery pack, two end insulating sheets 2, two fixed end plates 1, cover plate 6, plastic bracket 1312, output pole 3, FPC4, bus aluminum sheet 5, plastic strap 9, metal strap 10 and a reinforcing plate 8, the battery pack includes four cell groups 7, each cell group 7 includes several single cells, and the single cells are bonded by glue to form a cell group 7, 4 cell groups 7 is arranged in double rows, the intermediate insulating sheet 11 is arranged between the two rows of cell groups 7, the reinforcement plate 8 is arranged between the two rows of cell groups 7, and the two fixed end plates 1 clamp and fix the battery group, The end insulating sheet 2 is installed between the fixed end plate 1 and the battery pack. The four cell packs 7 are bound by the metal strap 10 and the plastic strap 9 to form a whole battery pack. The plastic bracket 1312 is installed on the upper end of th...

Embodiment 2

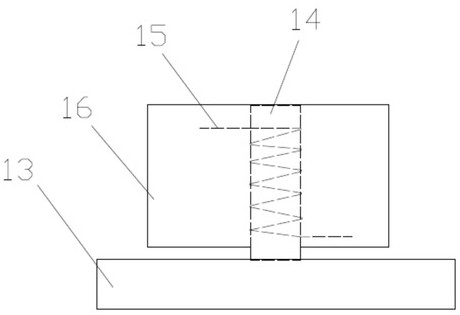

[0023] Embodiment 2, a battery module, such as image 3 As shown, the difference between the present embodiment and the first embodiment is that the reinforcing plate 8 of the present embodiment includes a base, a fixed rod 14, a torsion spring 15 and a movable plate 16, the base is installed between the battery packs 7, and the fixed rod 14 is fixedly installed on the base, the torsion spring 15 is installed on the fixed rod 14, the movable plate 16 is provided with a mounting groove matching the torsion spring 15, and the movable plate 16 is movably installed on the fixed rod 14 through the matching connection of the mounting groove and the torsion spring 15 Above, the cover plate 6 is also provided with a limit hole matching the cover plate 6 , and the elastic potential energy of the torsion spring 15 is smaller than that of the plastic strap 9 . All the other structures are the same as in Embodiment 1.

[0024] In a specific application, glue is first applied to each sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com