High-power variable-dip-angle continuous section node array antenna

An array antenna, high-power technology, applied in specific array feeding systems, antennas, antenna arrays, etc. Strong distance communication capability, long antenna action distance, safe and effective transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments and effects of the present invention will be further described in detail below with reference to the accompanying drawings.

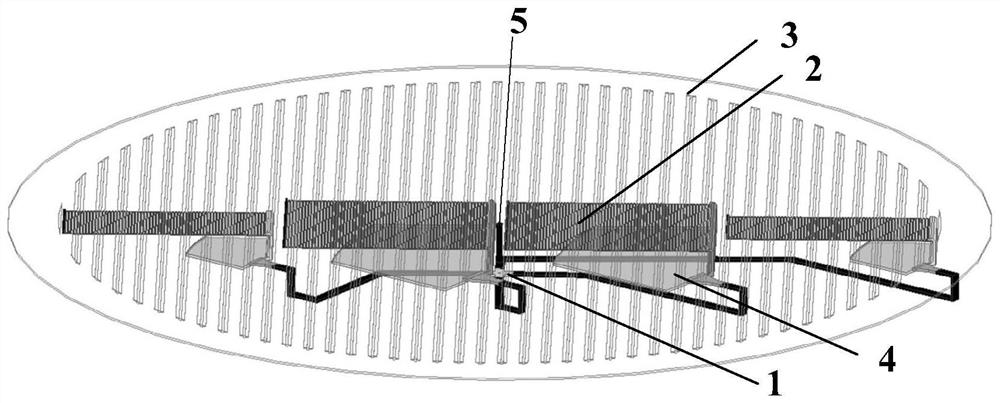

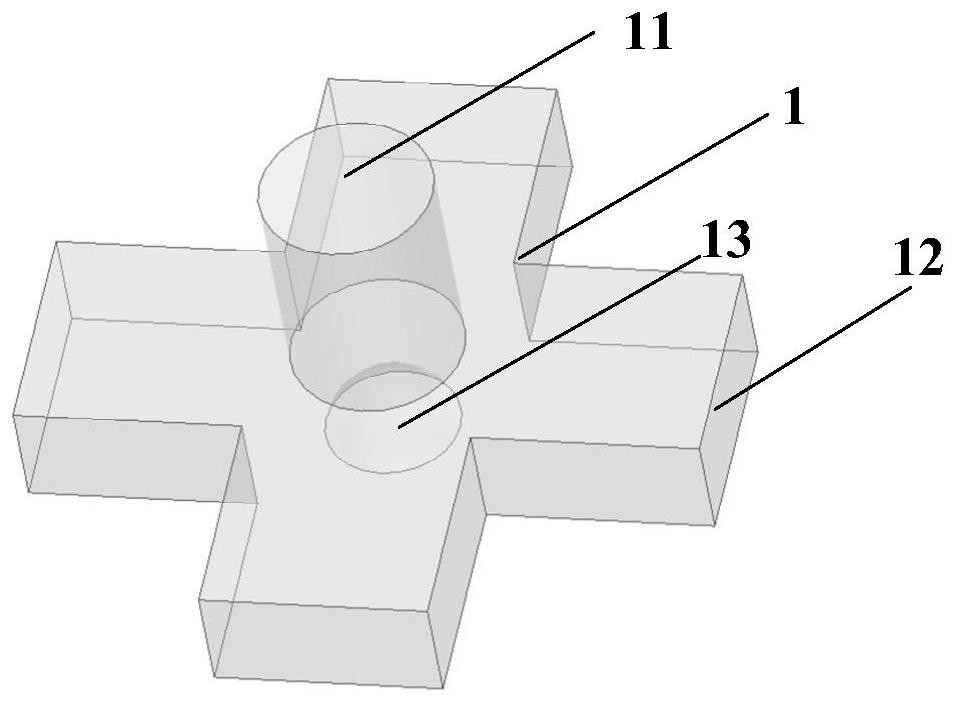

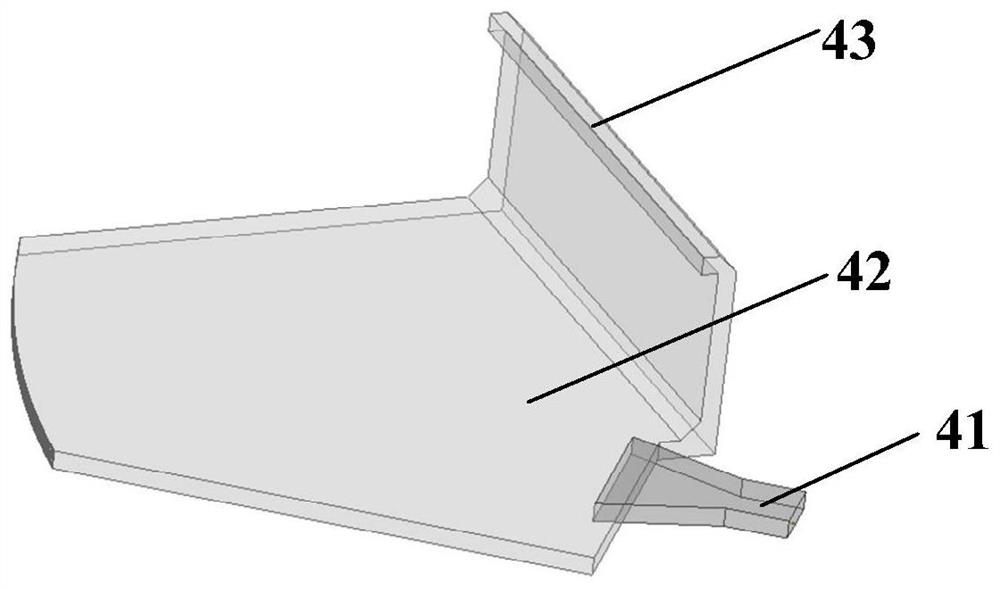

[0034] Refer figure 1 This example includes a power divider 1, a lower metal feed base plate 2, an upper metal disc 3, a bias parabolic reflection cartridge 4. The power divider 1 is located directly below the center of the lower metal feed base plate 2 and the upper metal disc 3, and there are a plurality of output terminals, respectively, respectively, by the H-surface turning waveguide, respectively, parabolic reflection box 4 The lower metal feed base plate 2 is divided into several sub-array along the propagation direction, and the present example is divided into four sub-array; the upper metal disc 3 is provided with a rotating joint 5 between the lower metal feed base plate 2, and is located on the upper metal The central position of the disc 3 is to ensure that the lower metal feed base plate 2 and the upper metal dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com