Polyethylene with additives for increased environmental stress crack resistance

An environmental stress cracking and additive technology, applied in the field of high-density polyethylene compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Application of different main additives to improve the ESCR performance of multimodal HDPE (HDPE-1 and HDPE-2) with a melt flow rate of 0.6–0.8 dg / min measured according to the ISO 1133 method at 190°C and a load of 2.16Kg , The density measured by ASTM D1505 or ISO 1872 method is 953-955Kg / m 3 , The tensile modulus measured according to the ISO 527-2 method is 1100-1200MPa, the yield tensile strength measured according to the ISO 527 1&2 method is 20-28MPa, and the izod notched impact strength measured according to the ISO 180 / A method at 23°C 8-12kJ / m 2 and a Charpy impact strength of 8-10kJ / m measured at 23°C according to the ISO 179 method 2 .

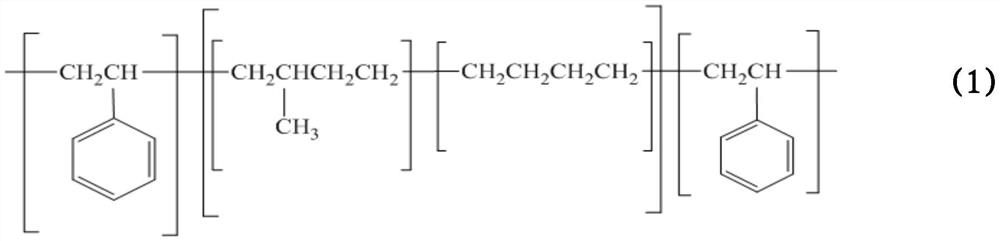

[0071] The applied HDPE-1 and HDPE-2 include Laboratory grade multimodal HDPE and INEOS CAP 602 multimodal HDPE. Primary additives include Septon by Kuraray America, Inc. TM Hydrogenated styrene block copolymers of styrene-ethylene-ethylene-propylene-styrene (SEEPS) obtained from Kraton Polymers as Kraton D TM Styrene...

Embodiment 2

[0076] The granules obtained after melt extrusion in Example 1 were compression molded at a temperature of 195-210° C. into a sheet with a thickness of 1.85-1.95 mm, and the holding time was 5 minutes and the cooling time was 5 minutes. No significant visual non-uniformity was seen in the compression molded sheet. Then according to ASTM D1693-15B method (Bell test) to evaluate the ESCR performance of pure HDPE and compression molded sheet of HDPE.

[0077] The compression molded sheet was cut into test specimens of 38 mm in length and 13 mm in width. A notch with a depth of 0.5 mm was formed in the center of each test sample before storing each sample in a conditioned environment at 23°C and a relative humidity of 55%. The conditioned sample was bent in a U shape with the aid of a clamp. For pure HDPE material and formulated HDPE material, 10 bent samples were put into aluminum sample holders respectively, and then placed in a solution filled with 10v / v% Igepol CO-630 (nonyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com