Platform for analyzing heavy electric equipment health and analysis method using same

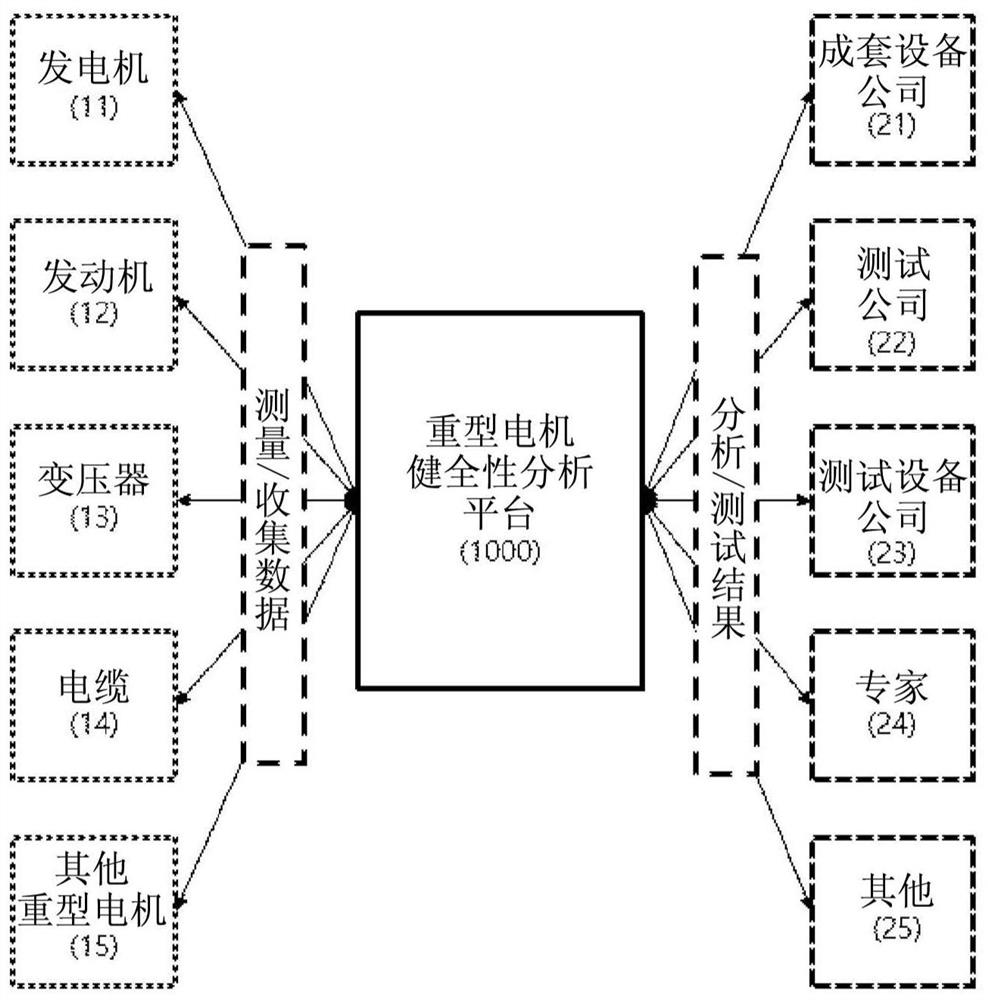

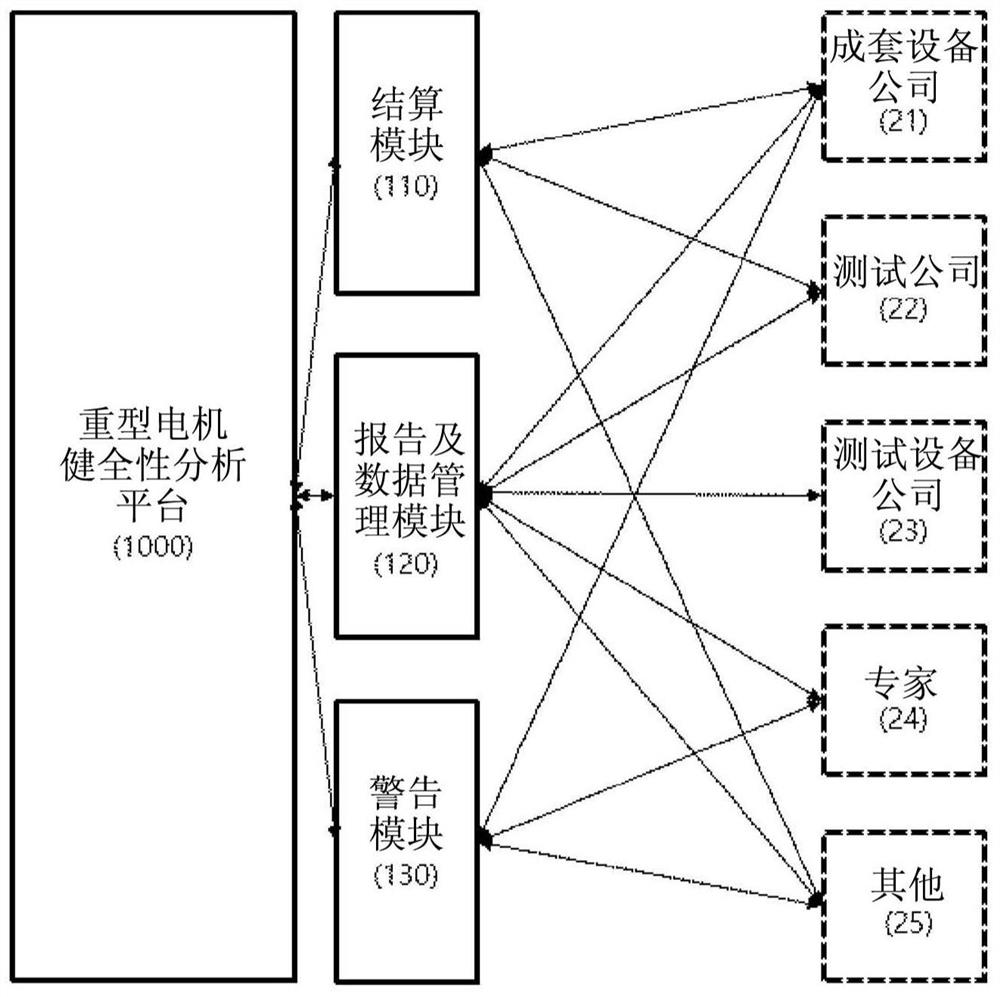

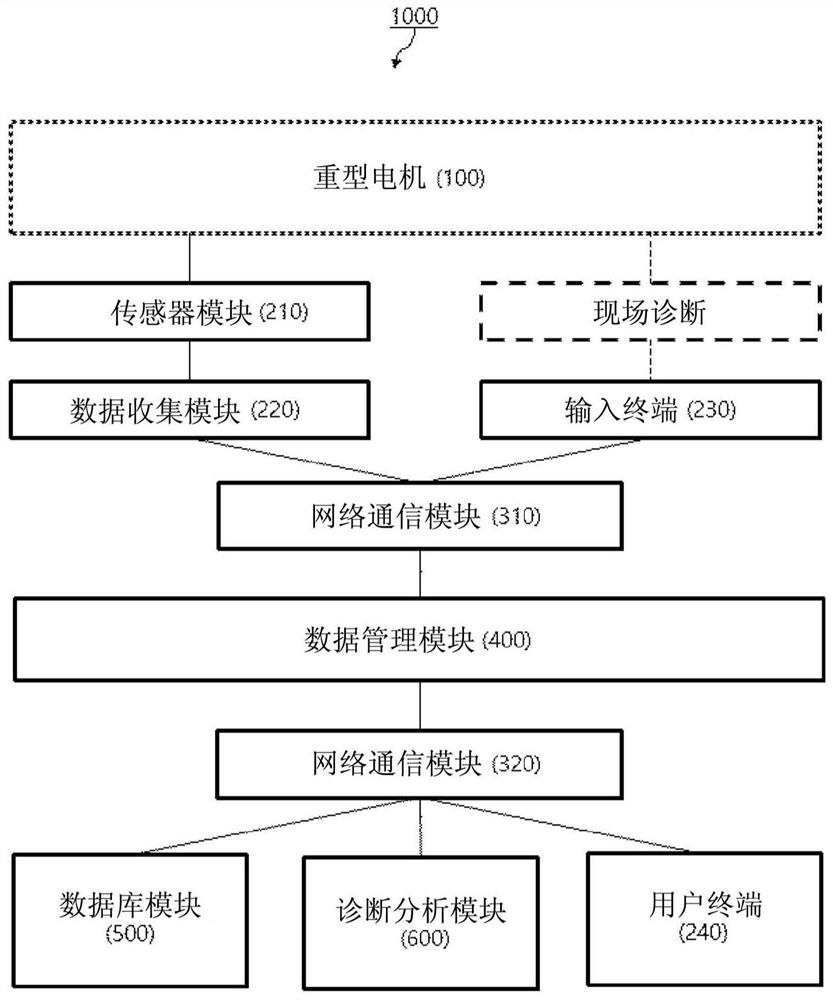

A robust, heavy-duty technology that is used in motor generator testing, registering/instructing machine work, measuring electricity, etc. It can solve problems such as difficult to predict failures, different characteristics, inconvenient management of historical data for soundness, and achieve accurate failure prediction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Hereinafter, the embodiments disclosed in this specification will be described in detail with reference to the drawings, and the same or similar structural elements will be given the same reference numerals regardless of the drawings, and repeated descriptions thereof will be omitted. The suffixes "module" and "unit" of the structural elements used in the following description are given or mixed only in consideration of ease of writing the description, and they themselves do not have different meanings or functions. In addition, in the process of describing the embodiments disclosed in this specification, when it is judged that the specific description of related known technologies may unnecessarily obscure the gist of the embodiments disclosed in this specification, the description will be omitted. detailed instructions. And, it should be understood that the accompanying drawings are only used to facilitate understanding of the embodiments disclosed in this specificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com