Welding method of battery cover plate

A welding method and battery cover technology, applied in welding equipment, laser welding equipment, battery pack components, etc., can solve problems such as deformation and shell deformation, and achieve improved safety in use, full molding, and avoid damage to cells Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

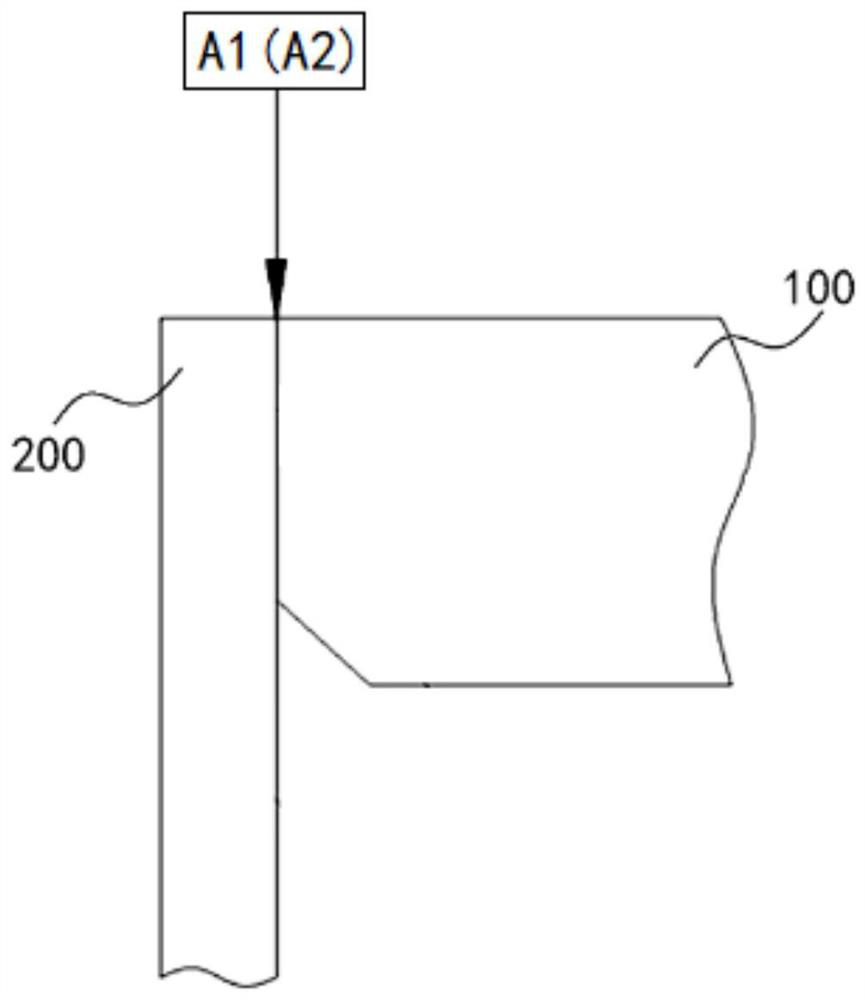

[0025] refer to figure 1 , which representatively shows the positions of two consecutive weldings on the cover plate 100 and the casing 200 of the battery cover plate welding method proposed by the present invention. In this exemplary embodiment, the method for welding the battery cover plate proposed by the present invention is described by taking the application of welding the aluminum shell of the vehicle battery and the cover plate 100 as an example. Those skilled in the art can easily understand that, in order to apply the related design of the present invention to the cover plate welding process of other types of batteries, various modifications, additions, substitutions, deletions or modifications are made to the following specific embodiments. Other variations, which are still within the scope of the principle of the welding method of the battery cover plate proposed by the present invention.

[0026] Such as figure 1 As shown, in this embodiment, the welding method ...

Embodiment 2

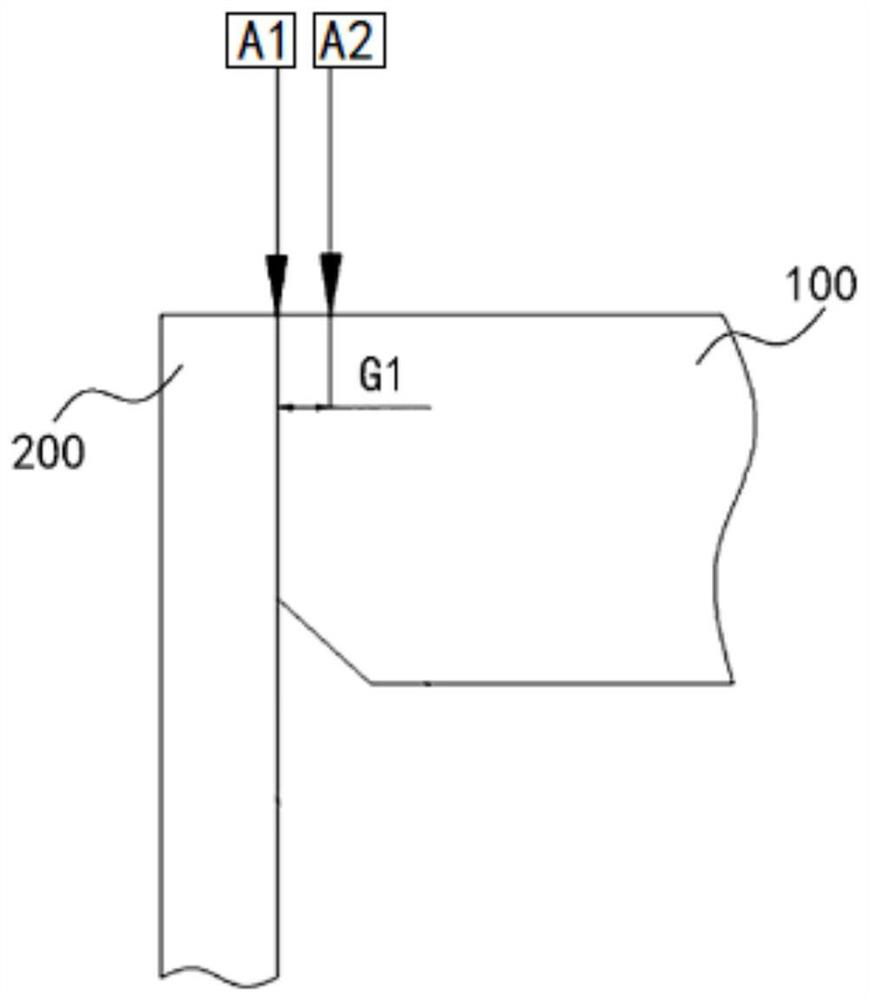

[0048] Based on the above detailed description of the first embodiment of the battery cover welding method proposed in the present invention, the second embodiment of the battery cover welding method proposed in the present invention will be described below. refer to figure 2 , which representatively shows the welding method of the battery cover plate proposed by the present invention, and a schematic diagram of the positions of two consecutive weldings on the cover plate 100 and the casing 200 in the second embodiment. The following will combine figure 2 , the design of the welding method in the second embodiment that is different from that in the first embodiment will be described.

[0049] Optionally, as in figure 2 As shown, in this embodiment, in the step of performing the first continuous welding along the connection area between the cover plate 100 and the housing 200, the position A1 of the welding beam (such as a laser beam) can be aligned with the cover plate 10...

Embodiment 3

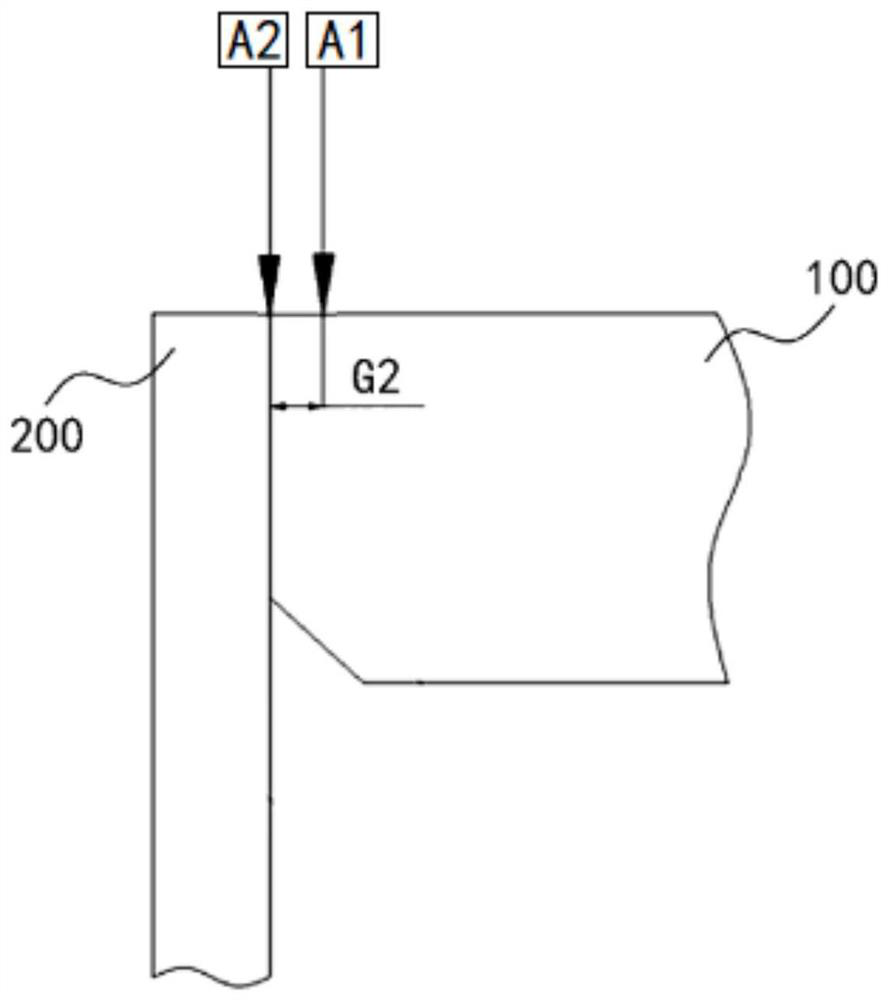

[0065] Based on the above detailed description of the first embodiment and the second embodiment of the battery cover welding method proposed by the present invention, the third embodiment of the battery cover welding method proposed by the present invention will be described below. refer to image 3 , which representatively shows the welding method of the battery cover plate proposed by the present invention, and a schematic diagram of positions of two consecutive weldings on the cover plate 100 and the casing 200 in the third embodiment. The following will combine image 3 , the design of the welding method in the third embodiment is different from that of the first embodiment and the second embodiment.

[0066] Optionally, as in image 3 As shown, in this embodiment, in the step of performing the first continuous welding along the connecting area between the cover plate 100 and the housing 200, the position A1 of the welding beam can be aligned with the position of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com