Preparation method of high-volume plant-mixed hot recycled asphalt mixture

A technology for asphalt mixture and thermal regeneration, applied in the field of highway construction materials, can solve the problems of ineffective application, large impact on the quality of old RAP materials, and large variability, achieve significant social and economic benefits, improve traffic capacity, The effect of removing variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

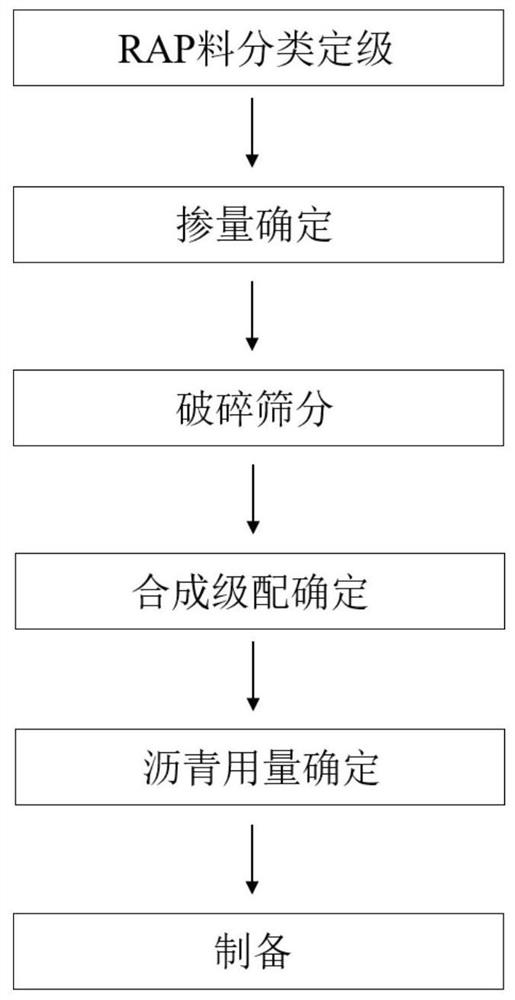

[0044] The preparation method of the high-volume plant-mixed hot recycled asphalt mixture of this embodiment, such as figure 1 As shown, the specific steps are as follows:

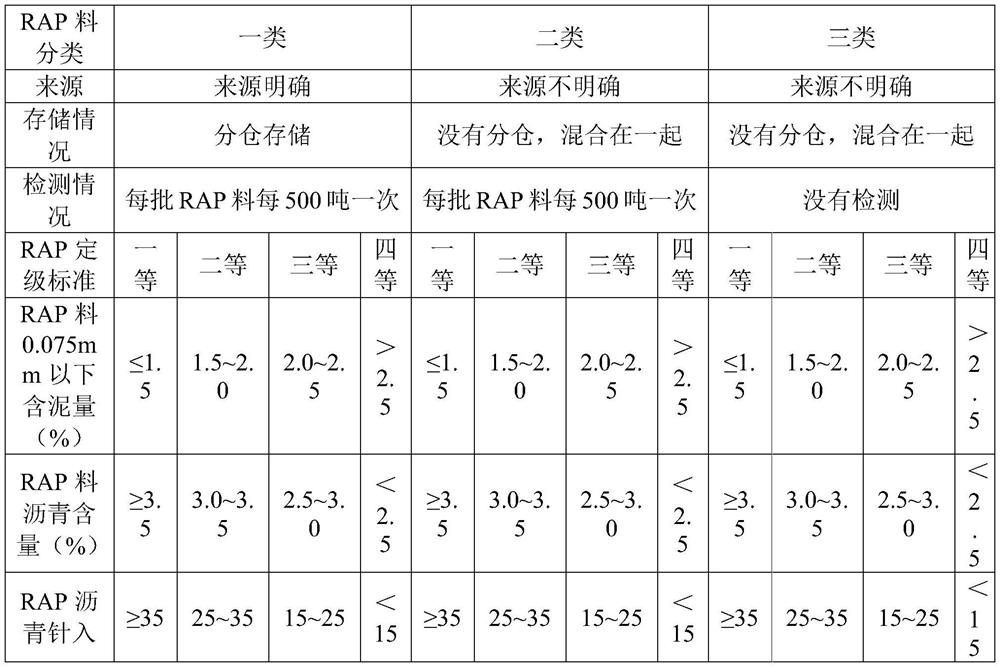

[0045]Step 1. Classification and grading of RAP materials. Classify RAP materials according to the source of RAP materials, storage conditions and testing conditions, and then classify various RAP materials according to the mud content below 0.075mm, asphalt content and asphalt penetration. class.

[0046] The basis for the classification and grading of RAP materials is shown in Table 1.

[0047] Table 1. RAP material classification and grading basis table

[0048]

[0049]

[0050] For the classification of RAP materials, you can ask the supplier or check the relevant records when purchasing RAP materials.

[0051] Step 2: Determine the dosage. According to the classification and grading results of RAP materials, different types and grades of RAP materials adopt different blending ratios.

[005...

Embodiment 2

[0090] This example shows the preparation method of AC-13C recycled asphalt mixture.

[0091] The AC-13C type recycled asphalt mixture of this embodiment includes the following components by weight: 55 parts by weight of Class II first-class recycled asphalt pavement reclaimed material; 40 parts by weight of crushed stone; 2.4 parts by weight of mineral powder; high glue and high viscosity 2.6 parts by weight of asphalt.

[0092] 1. Classify and grade the obtained old asphalt recycled material according to the regulations, and finally determine it as the second-class first-class RAP material, and then screen out the part of the RAP material below 0.3mm to determine the dosage of the RAP material.

[0093] 2. Mix the above-mentioned RAP materials mechanically and carry out crushing treatment, then carry out screening treatment, and sieve into 30% of the first coarse aggregate with a particle size of 0-10mm and 70% of the second coarse aggregate with a particle size of 10-15mm. ...

Embodiment 3

[0106] This example shows the preparation method of AC-20C recycled asphalt mixture.

[0107] The AC-20C type recycled asphalt mixture of this embodiment includes the following components by weight: 65 parts by weight of Class II primary recycled asphalt pavement reclaimed material; 32 parts by weight of crushed stone; 0.5 part by weight of mineral powder; high glue and high viscosity 2.4 parts by weight of asphalt.

[0108] 1. Classify and grade the obtained old asphalt recycled material according to the regulations, and finally determine it as the second-class first-class RAP material, and then screen out the part of the RAP material below 0.3mm to determine the dosage of the RAP material.

[0109] 2. Mix the above-mentioned RAP materials mechanically and carry out crushing treatment, then carry out screening treatment, and sieve into 30% of the first coarse aggregate with a particle size of 0-10mm and 70% of the second coarse aggregate with a particle size of 10-15mm. Coar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com