Process film for FPC manufacturing process, preparation method and application thereof

A technology of release film and pressure-sensitive adhesive layer, which is applied in the direction of pressure-sensitive film/sheet, film/sheet-shaped adhesive, adhesive type, etc., which can solve the problem of lamination failure, module damage, FPC sticking To solve the problems of low bonding efficiency, achieve high adhesion and adhesion, ensure effective bonding, good adhesion and pollution-free effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

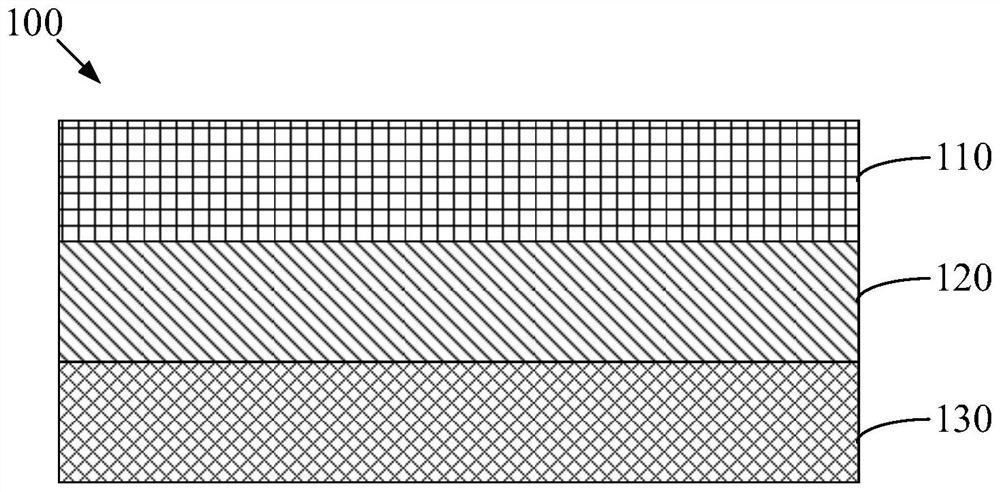

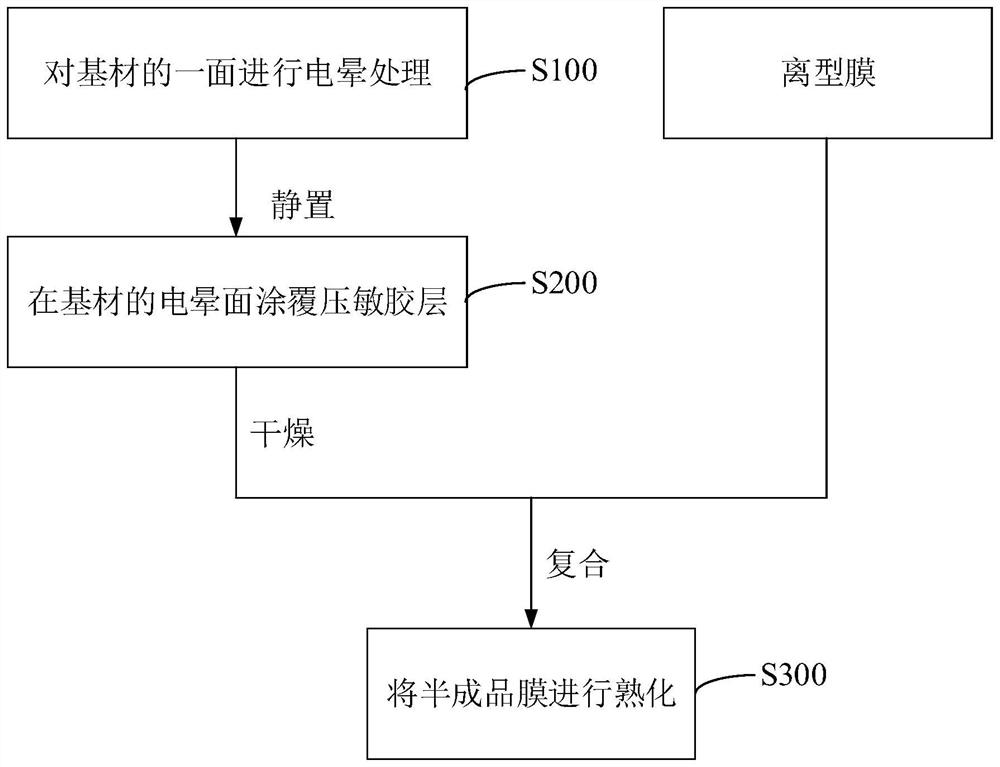

[0040] Correspondingly, the present application also provides a method for preparing the process film 100 for the FPC process, which is used to prepare the process film 100 for the FPC process described above. Specifically, see figure 2, the preparation method of the process film 100 for FPC process provided in the present application includes: step S100, after corona treatment is performed on one side of the substrate 110, it is left to stand for a first preset time. Here, it should be pointed out that the substrate 110 used can be made of PET, PO, PVC or PP, etc., which can be adjusted according to usage requirements. Also, the thickness of the base material 110 may be set to 50 μm. The parameters of the corona treatment process for the substrate 110 can be set according to different corona devices and different requirements for surface energy. In a possible implementation manner, the power of the corona device may specifically be set to: 1.9KW.

[0041] Then, through st...

Embodiment 1

[0046] It should be noted that, in this embodiment, the preparation process of the process film 100 for the FPC process is as follows:

[0047] Firstly, a PET film is used as the substrate 110, and one side of the substrate 110 is subjected to corona treatment so that one side of the substrate 110 is a corona surface. Wherein, in this embodiment, the substrate 110 used has a thickness of 50 μm, and the process parameters for corona treatment on the substrate 110 are: the power of the corona device is set to 1.9KW.

[0048] After corona treatment is performed on the base material 110 , it is left to stand for a period of time (the standing time is: 1 day to 2 days, ie, 24 hours to 48 hours). At the same time, the components used to prepare the pressure-sensitive adhesive layer 120 are accurately weighed in sequence, added to the solvent and stirred evenly to obtain a pressure-sensitive adhesive.

[0049] Specifically, in this embodiment, 60 g of the resin as the main body of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com