Repair structure and repair method for underwater foundation structure scour pit

A technology for underwater foundations and repair structures, applied in the repair of foundation structures, foundation structure engineering, filling, etc., can solve problems such as erosion, reduce contact depth, reduce the bearing capacity and stability of underwater foundation structures, and achieve improved Anti-scouring ability, improving strength and water stability, and avoiding the effect of interface erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

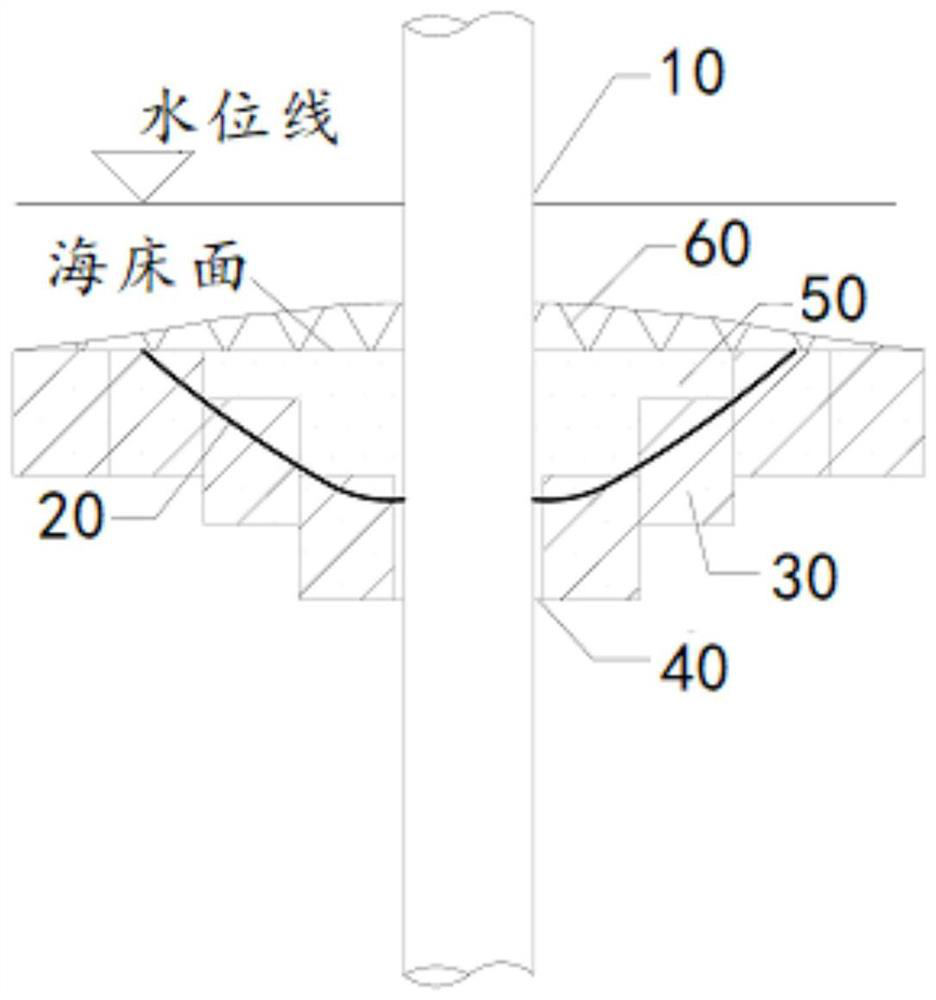

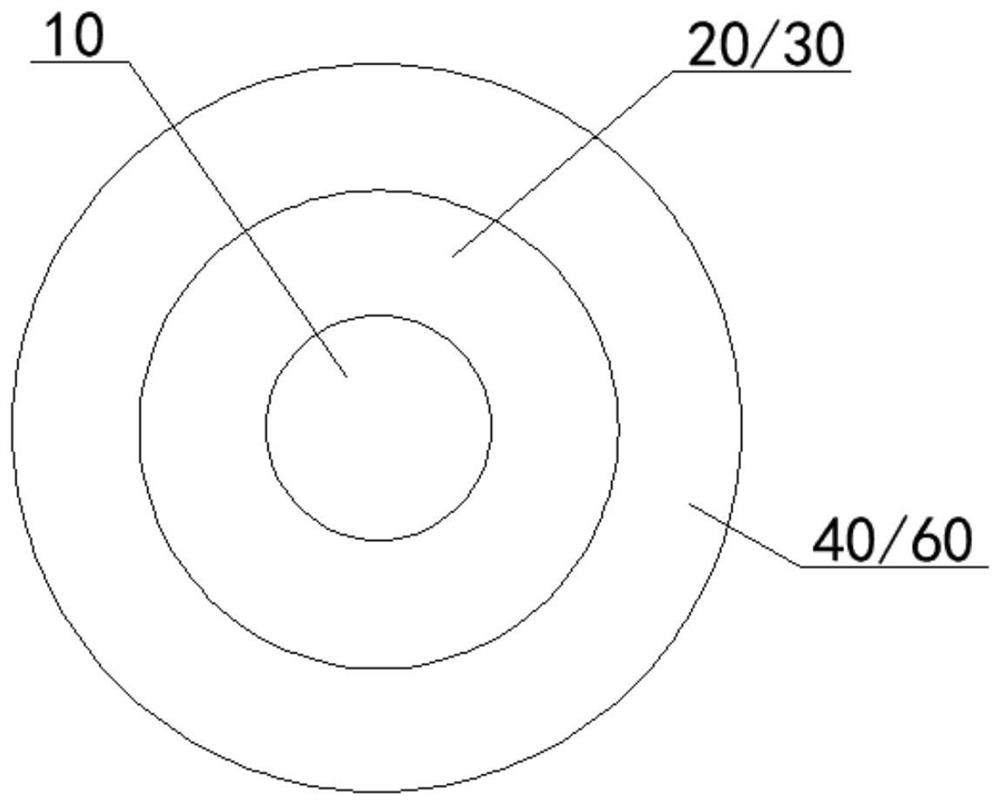

[0035] The repair structure of the scour pit of the underwater foundation structure of the present invention includes a scour pit foundation solidification structure 30, a scour pit backfill solidification structure 50 and an anti-scouring protection solidification structure 60; wherein,

[0036] The scour pit foundation solidification structure 30 is a plurality of solidified soil piles 3 driven into the bottom surface of the scour pit 20 and the peripheral seabed of the scour pit 20, each solidified soil pile 3 is a mixing pile, and the pile type of the solidified soil pile 3 is Rectangular with an effective plane size of 1.6m×2m, multiple solidified soil piles 3 form closed piles by engaging with each other for 10cm; the scour pit foundation solidification structure 30 and the underwater foundation structure 10 are connected by a solidification agent 40 The distance from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com