Wall plate, wall body using wall plate and installation method of wall body

A wall panel and wall technology, applied in the direction of walls, buildings, industrial buildings, etc., can solve the problems of wear or deformation, the curvature of a single panel, and the uneven unevenness of horizontal adjacent panels, saving raw materials, facilitating transportation, Beautiful installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

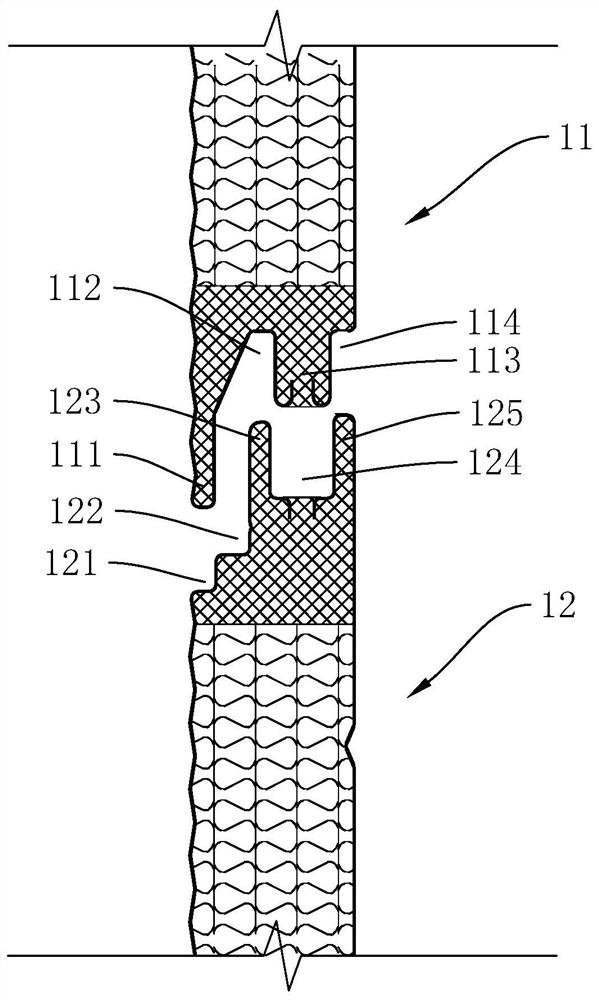

[0071] refer to image 3 , discloses a wallboard 1 for this application, the left side in the figure is the outside of the wall, and the right side is the inside of the wall. Wallboard 1 comprises lower end plate 11 and upper end plate 12, and lower end plate 11 comprises lower first protrusion 111, lower first groove 112, lower second protrusion 113 and lower second groove 114, lower first protrusion 111 The protrusion height is greater than the protrusion height of the lower second protrusion 113, and the height of the bottom of the lower first groove 112 and the lower second groove 114 is the same; the upper end plate 12 includes an upper first step 121, an upper second step 122 , the upper first protrusion 123, the upper groove 124 and the upper second protrusion 125, the lower second protrusion 113 can be inserted into the upper groove 124, and the lower first protrusion 111 can cooperate with the upper first step 121 , the height of the upper first step 121 is lower tha...

Embodiment 2

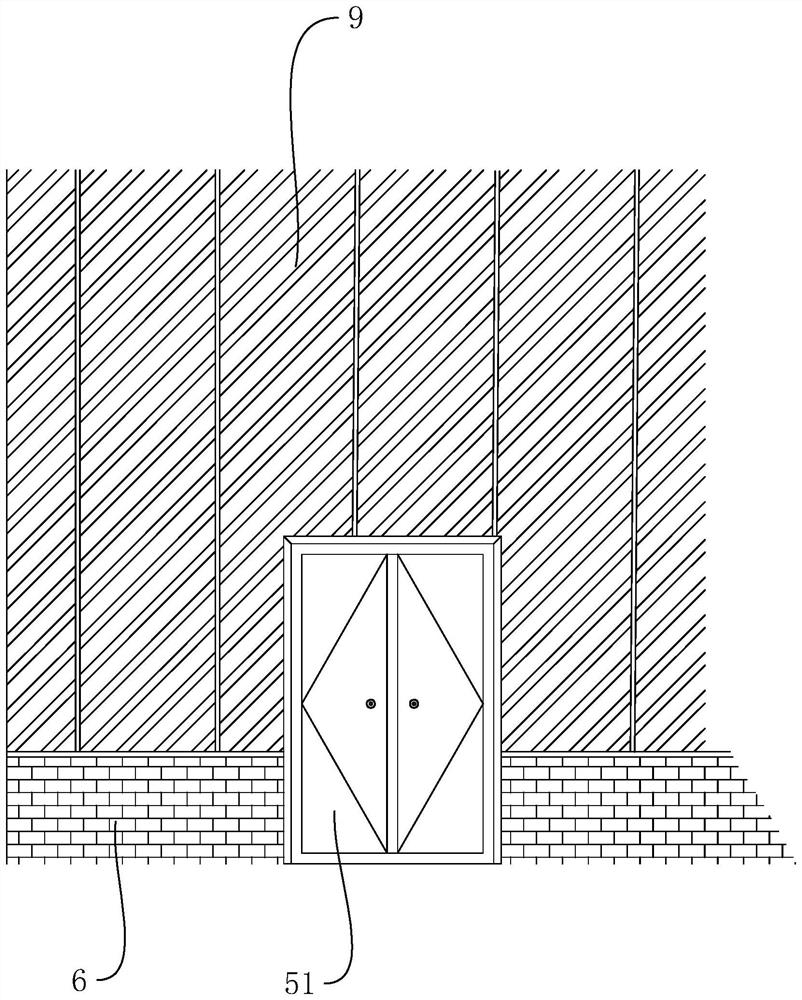

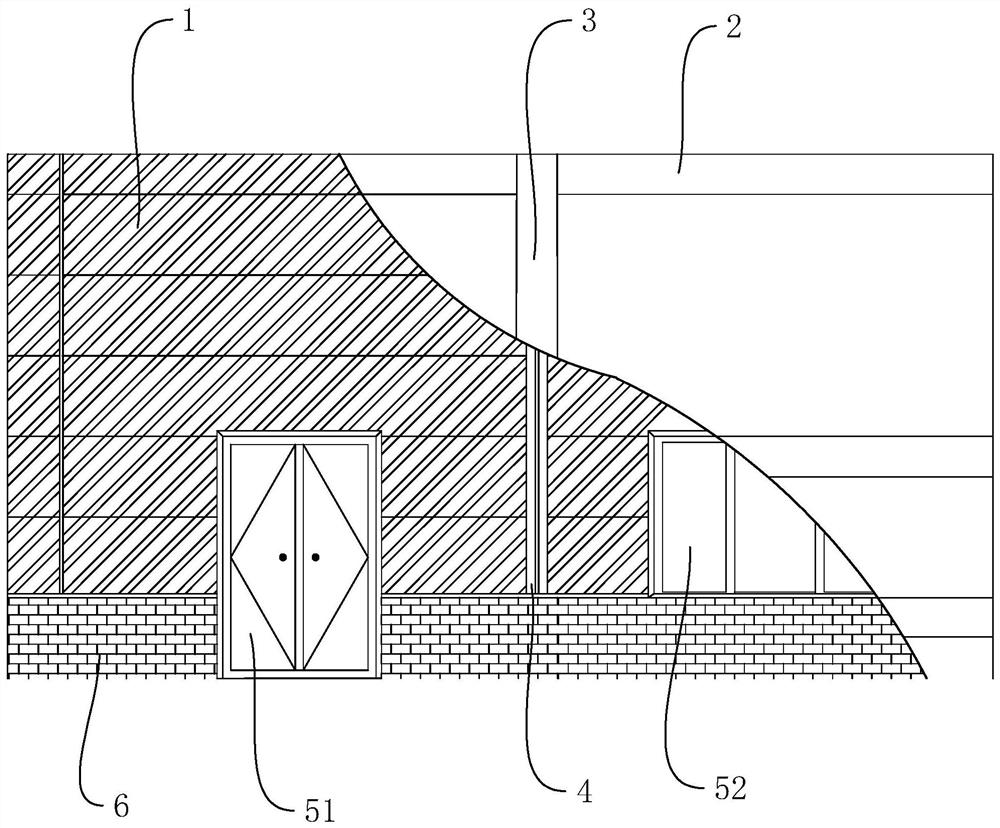

[0075] A wall body using the above-mentioned wallboard 1 includes purlins 2 , purlins 3 , and U-shaped grooves 4 connecting the wallboard 1 to the purlins 3 . refer to Figure 4 and Figure 5 , the two ends of the vertical purlin 3 are respectively covered by two horizontally adjacent wallboards 1, a gap of 2 cm is provided between the two wallboards 1, and a strip-shaped insulating block 8 is placed in the vertical direction in the gap, Protrude 42 for the U groove with a groove width of 1.5cm (such as Figure 5 shown) inserted into the gap between the two wall panels, and the U-shaped groove 4 and the insulation block 8 are fixed on the vertical purlin 3 by self-tapping screws.

[0076] The U-groove corner 41 of the U-shaped groove 4 presses the wall panel 1 to connect it with the vertical purlin 3, and glues the contact between the U-groove corner 41 and the wall panel 1, on the one hand to increase firmness, and on the other hand to make it airtight , no water leakage. ...

Embodiment 3

[0080] A kind of wall body, the connection structure of chopping wall 6 and wall board 1 refers to Figure 6 , both the fixing piece 72 and the corner piece 71 are in a “Z” shape, the bends are 90°, and one end of the corner piece 71 is provided with a groove tail 712 . At the joint between the wallboard 1 and the cut wall 6, use one end of the fixing piece 72 to press the end of the non-groove tail 712 of the corner piece on the vertical purlin 3, so that the fixing piece 72 forms a cavity area at the top and bottom, and use a self-tapping screw Fixing, put the insulation block 8 in the cavity under the fixing part 72, snap the lower second protrusion 113 of the lower end plate 11 of the wallboard 1 into the cavity on the fixing part 72, make the lower first protrusion The inner side of 111 abuts against the insulation block 8 .

[0081] The implementation principle of this embodiment is: only one fixing piece 72 and one corner piece 71 are used to realize the connection bet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap