Photoetching machine motion table system

A motion table and lithography machine technology, applied in the field of lithography machines, can solve the problems of surrounding air disturbance, influence, local pressure fluctuation can not be ignored, etc., to achieve the effect of ensuring stable operation and avoiding the expansion of airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

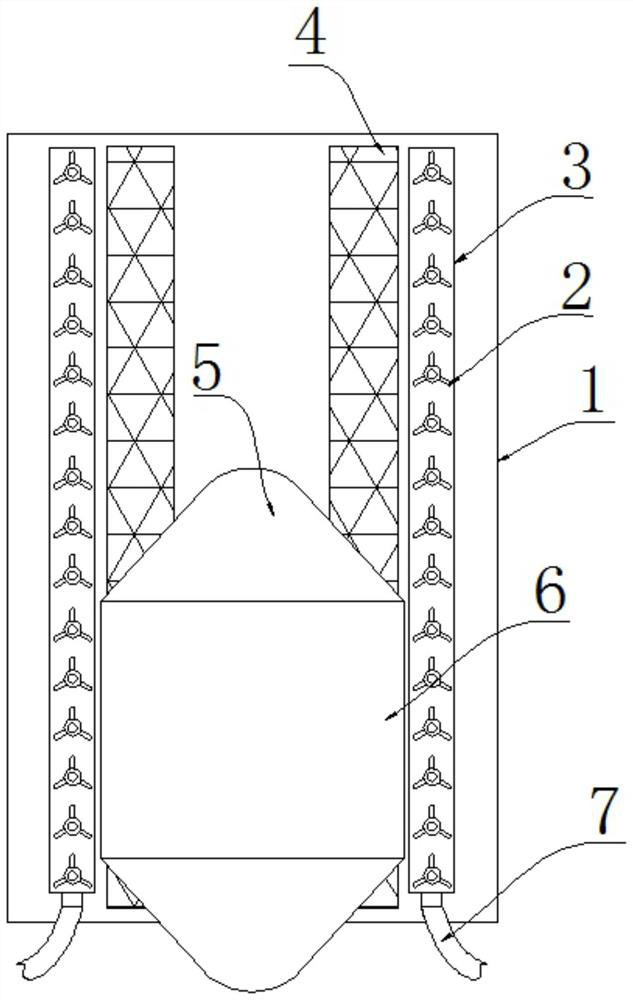

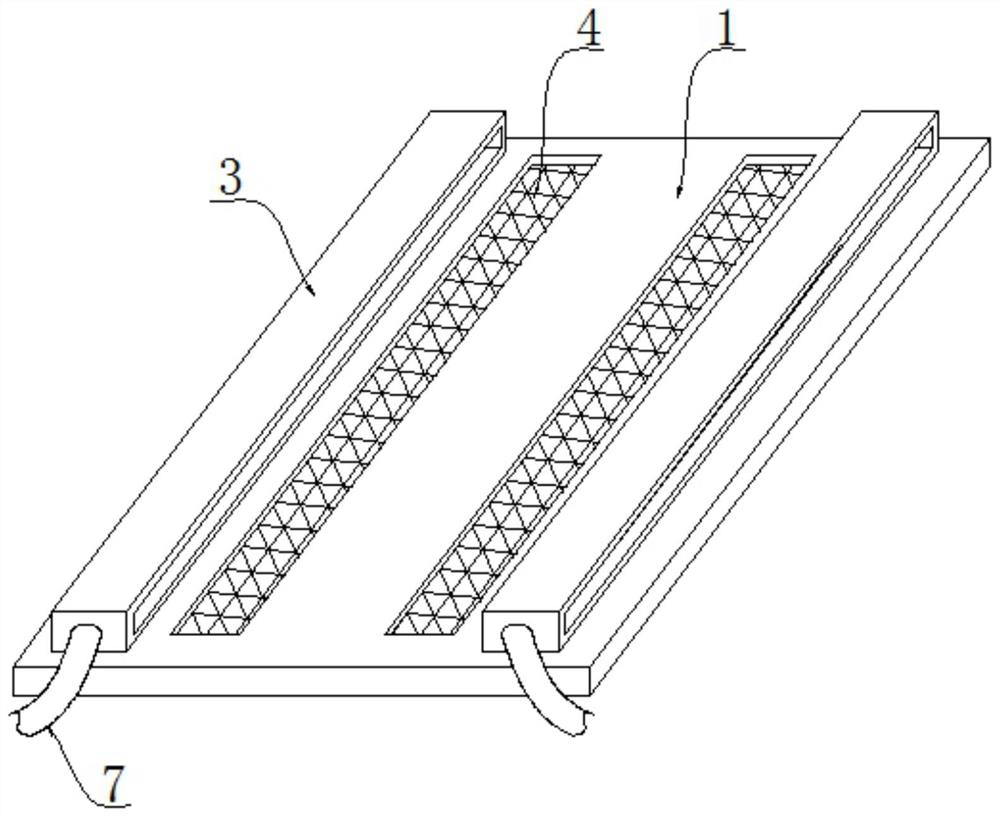

[0025] see figure 1 As shown, in the embodiment of the present invention, a lithography machine moving table system includes a base 1 and a moving table 6 above the base 1, and the moving table 6 can move above the base 1;

[0026] combine figure 1 and figure 2 As shown, both sides of the upper surface of the base 1 are equipped with anti-expansion cover 3, and the anti-expansion cover 3 is a ventilation structure on both sides. external transmission;

[0027] combine figure 1 and Figure 4 As shown, the inside of the anti-expansion cover 3 is equipped with side-by-side wind collection assemblies 2, the wind collection assembly 2 includes a central shaft 21 fixed inside the anti-expansion cover 3, and the circumference of the central shaft 21 is installed with a mounting cylinder 24 for rotation. The outside of 24 is uniformly equipped with fan blades 23. When the air flow passes through the anti-expansion cover 3, it will push the fan blades 23, so that the fan blades 3...

Embodiment 2

[0036] see figure 1 As shown, in the embodiment of the present invention, a lithography machine moving table system includes a base 1 and a moving table 6 above the base 1, and the moving table 6 can move above the base 1;

[0037] combine figure 1 and figure 2 As shown, both sides of the upper surface of the base 1 are equipped with anti-expansion cover 3, and the anti-expansion cover 3 is a ventilation structure on both sides. external transmission;

[0038] combine figure 1 and Figure 4 As shown, the inside of the anti-expansion cover 3 is equipped with side-by-side wind collection assemblies 2, the wind collection assembly 2 includes a central shaft 21 fixed inside the anti-expansion cover 3, and the circumference of the central shaft 21 is installed with a mounting cylinder 24 for rotation. The outside of 24 is uniformly equipped with fan blades 23. When the air flow passes through the anti-expansion cover 3, it will push the fan blades 23, so that the fan blades 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com