Comprehensive prediction method for wear increase of heat transfer tube of steam generator of nuclear power plant

A steam generator and comprehensive forecasting technology, applied in forecasting, instrumentation, electrical and digital data processing, etc., can solve problems such as inability to use accurately, inability to distinguish various types of wear, etc., to promote safe, reliable and economical operation, easy to operate and implement , the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

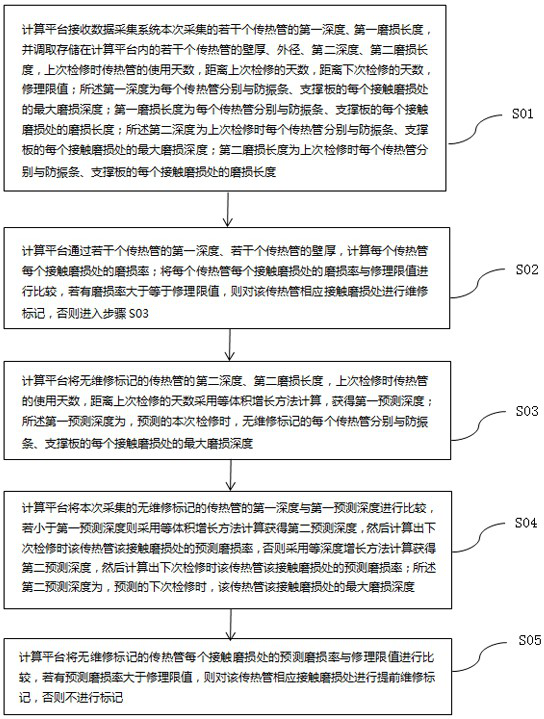

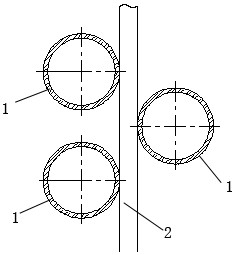

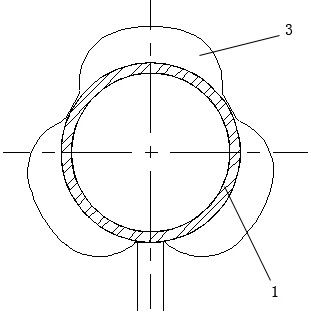

[0069] Such as Figure 1-7 A comprehensive prediction method for wear growth of steam generator heat transfer tubes in a nuclear power plant is shown, which is used to predict the wear occurring in the contact area between the heat transfer tube 1 and the support. Such as figure 2 As shown, anti-vibration strips 2 are arranged between adjacent heat transfer tubes 1 . Such as image 3 As shown, several support plates 3 are arranged outside each heat transfer tube 1 .

[0070] The anti-vibration strip 2 is tangent to the heat transfer tube 1, and the contact wear is a line contact mode, such as Figure 4 As shown, the axial shape of the wear surface at the contact wear point between the heat transfer tube 1 and the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com