Workpiece swing and offset detection system

A detection system and offset technology, applied in measuring devices, instruments, spray devices, etc., can solve problems such as failure to achieve timeliness, product quality impact, and unfavorable spray gun swing amplitude exceeding the standard fault.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

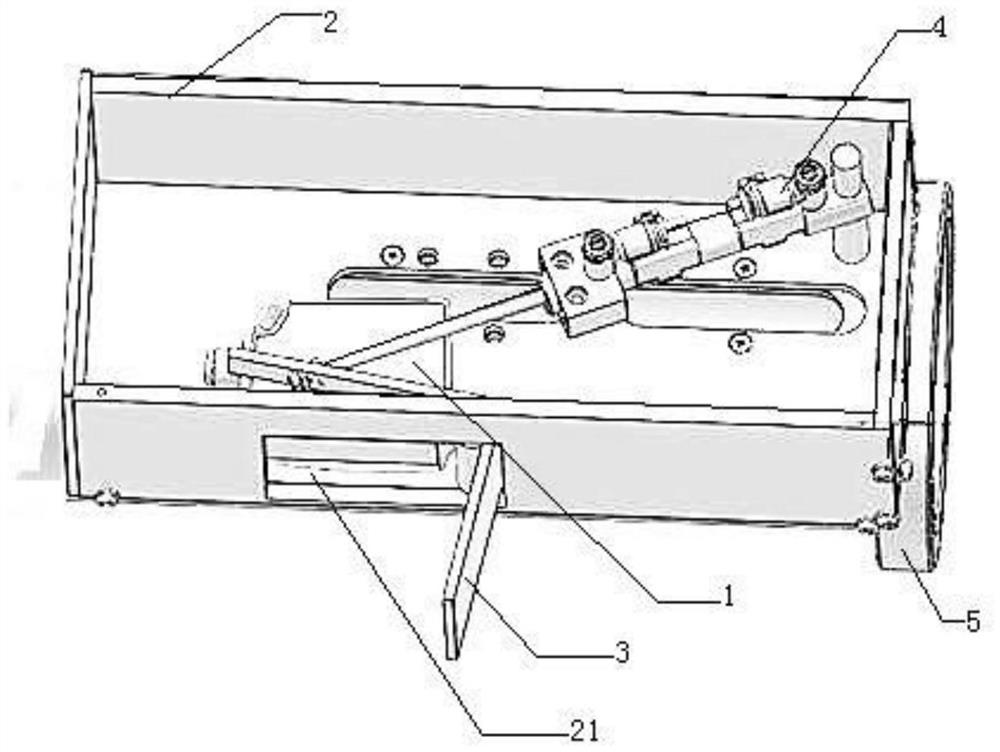

[0016] figure 1 , 2 As shown in , the workpiece swing and offset detection system includes a laser rangefinder 1, a housing 2, a movable door 3, a cylinder 4, a PLC (not shown in the figure), and an industrial computer (not shown in the figure); There are two sets of laser rangefinder 1, shell 2, "┑" type movable door 3, and cylinder 4 respectively. The front left part of the casing 2 has a rectangular opening 21, and the height of the front end of the movable door 3 is lower than that of the rear end. The middle part of movable plate 3 is rotated and installed in the front part of the housing 2 at the right side of the opening 21, and the laser range finder 1 is installed in the left front end of the housing, and its detection head is located at the rear end of the opening 21, behind the dodge door 3. The end is located on the upper part of the laser rangefinder 1, the right end of the cylinder body of the cylinder 4 is rotated and installed on the right end of the housing 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com