Accurate positioning and feeding mechanism of automobile plate spring rolling mill

A technology for precise positioning and automotive plates, applied in guiding/positioning/alignment devices, metal rolling, metal rolling, etc., can solve problems such as low production efficiency, low positioning accuracy, and long working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

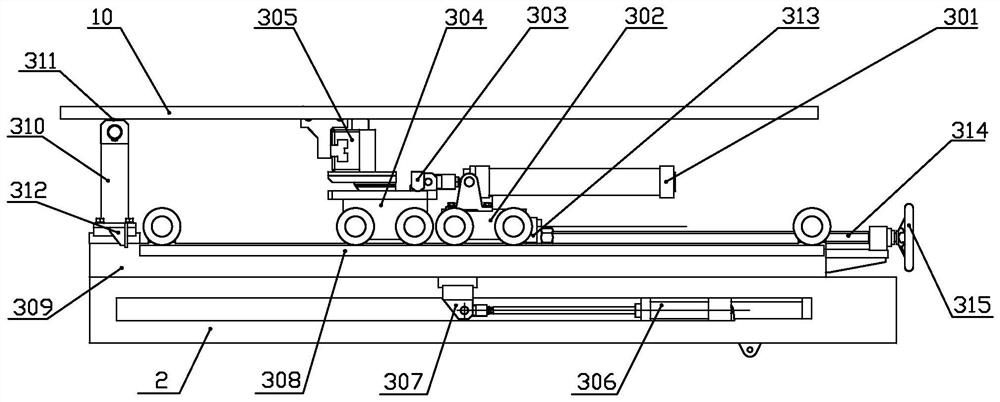

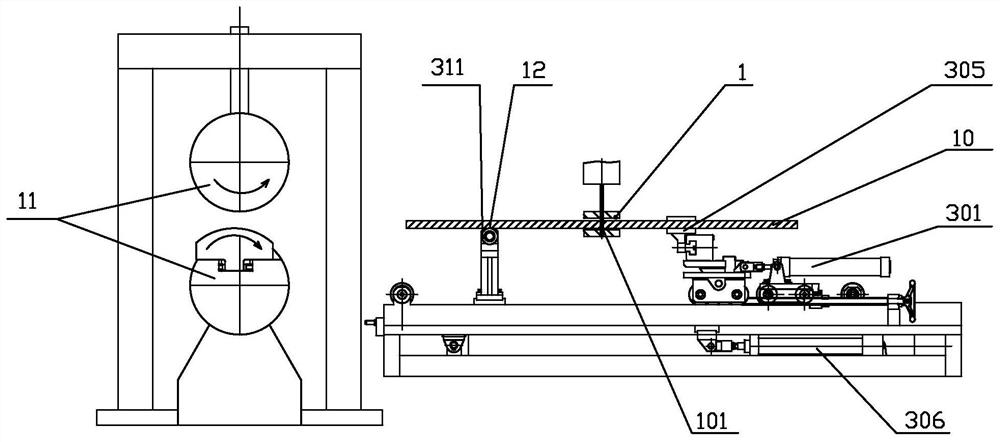

[0028] With reference to the accompanying drawings of the description, the precise positioning and feeding mechanism of the automobile leaf spring rolling mill of the present invention will be described in detail below. It should be noted that components illustrated in the figures are not necessarily drawn to scale. The present invention omits descriptions of well-known components and well-known technologies in order to avoid unnecessarily limiting the present invention.

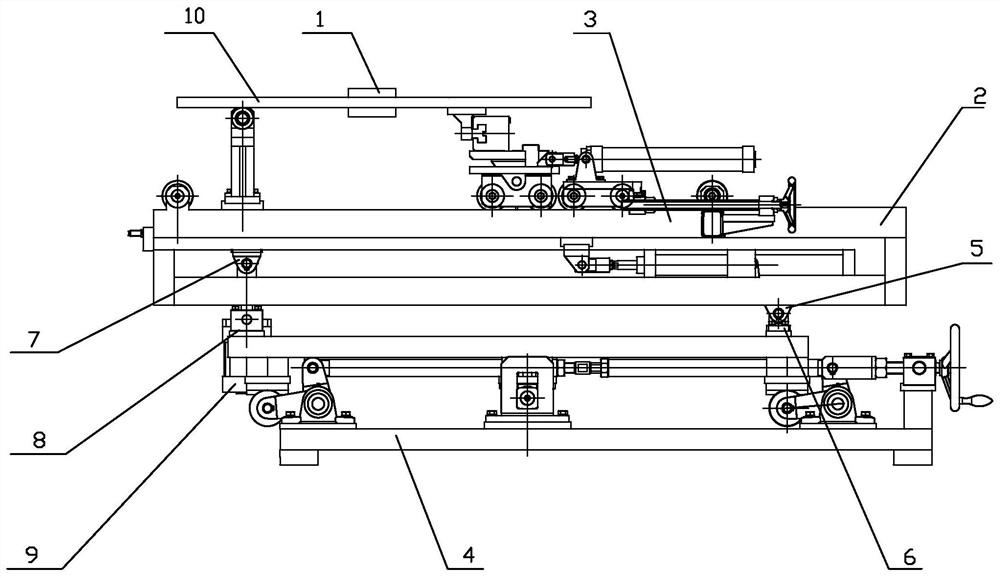

[0029] Such as Figure 1 to Figure 6 As shown, the automobile leaf spring rolling mill of the present invention accurately positions the feeding mechanism, including a feeding manipulator 1 for clamping the reed, a frame 2, a feeding device 3 for sending the reed to the roll of the rolling mill, a height adjustment device 4, an upper The hinged seat 5, the lower hinged seat 6 and the buffer mechanism, the feeding device 3 is arranged on the top of the frame 2 and is connected with the frame, the height adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com