Auxiliary clamping structure for workpiece and numerical control lathe

A technology of clamping structure and CNC lathe, applied in the direction of metal processing machinery parts, clamping, turning equipment, etc., can solve the general problems of cutting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

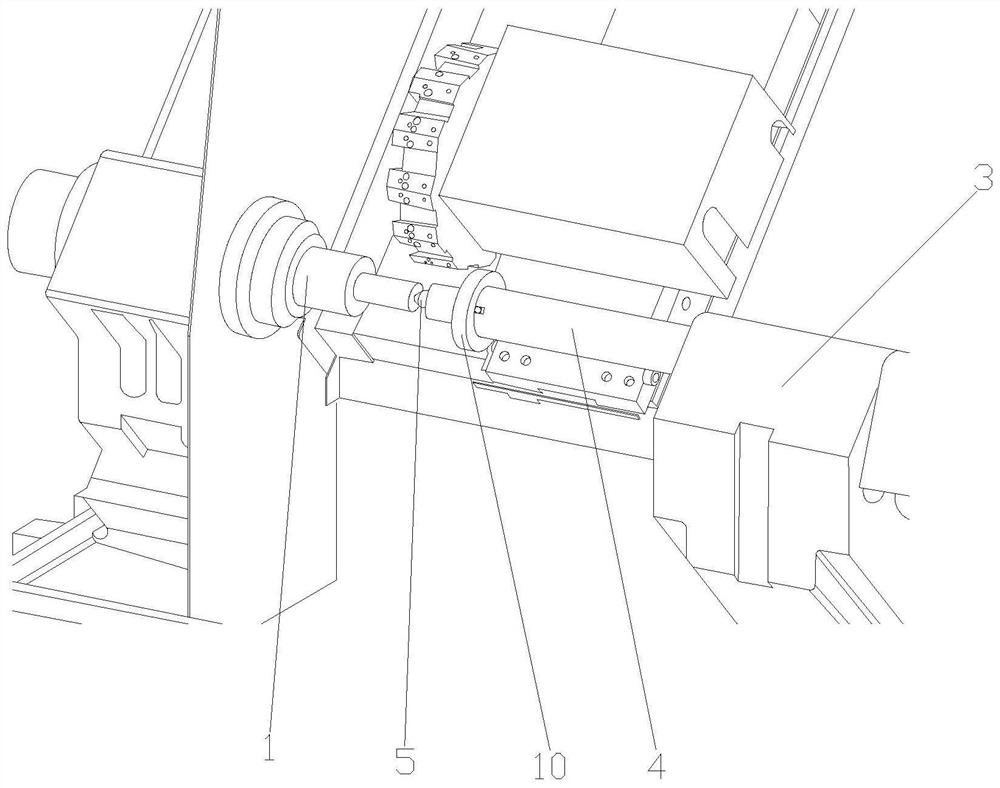

[0030] Such as Figure 1-6 Shown, a kind of auxiliary clamping structure of workpiece, comprises the main shaft mechanism assembly 1 that is arranged on the frame of CNC lathe; And the movable tail seat mechanism that is arranged on the frame of CNC lathe; The top seat includes a fixed base 3, a top sleeve 4 mounted on the fixed base 3 and movable laterally, and a top 5 for supporting the workpiece. The end of the top 5 is inserted into the top sleeve 4 and connected with the top sleeve 4 In rotational connection, the center of the top sleeve 4 is located on the same level as the center of the main shaft in the main shaft mechanism assembly 1 .

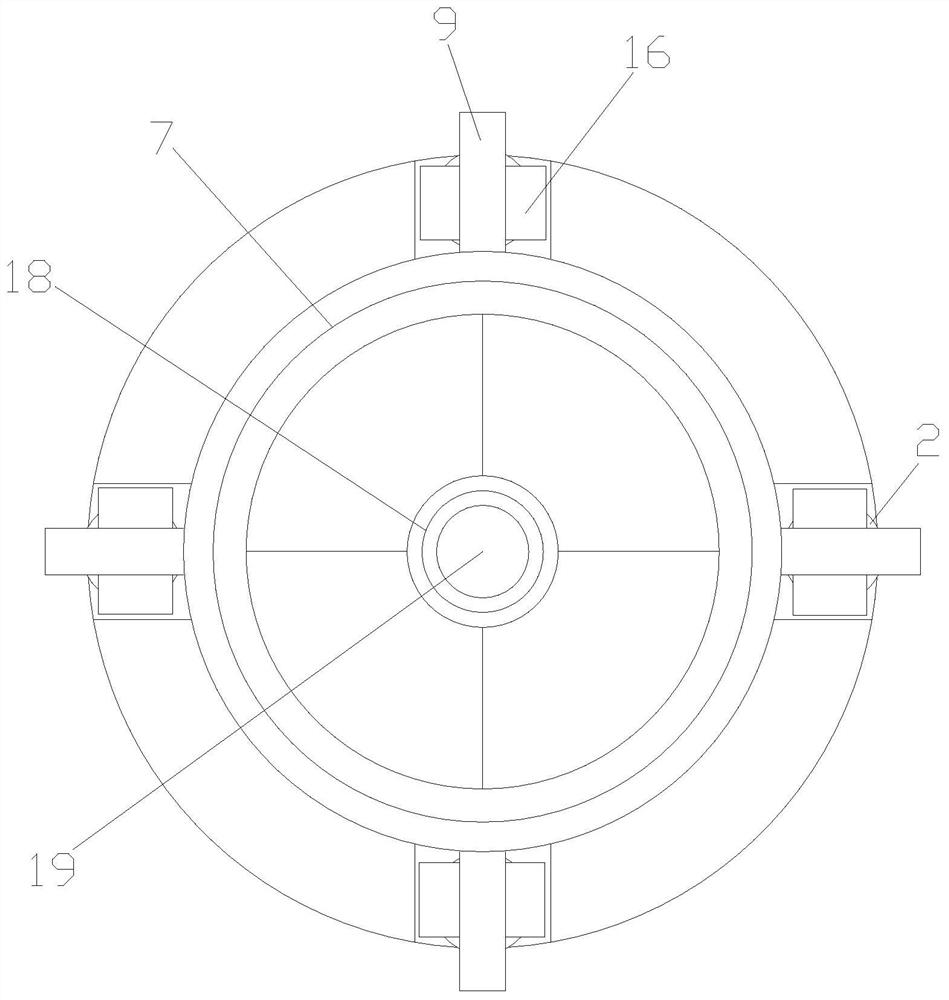

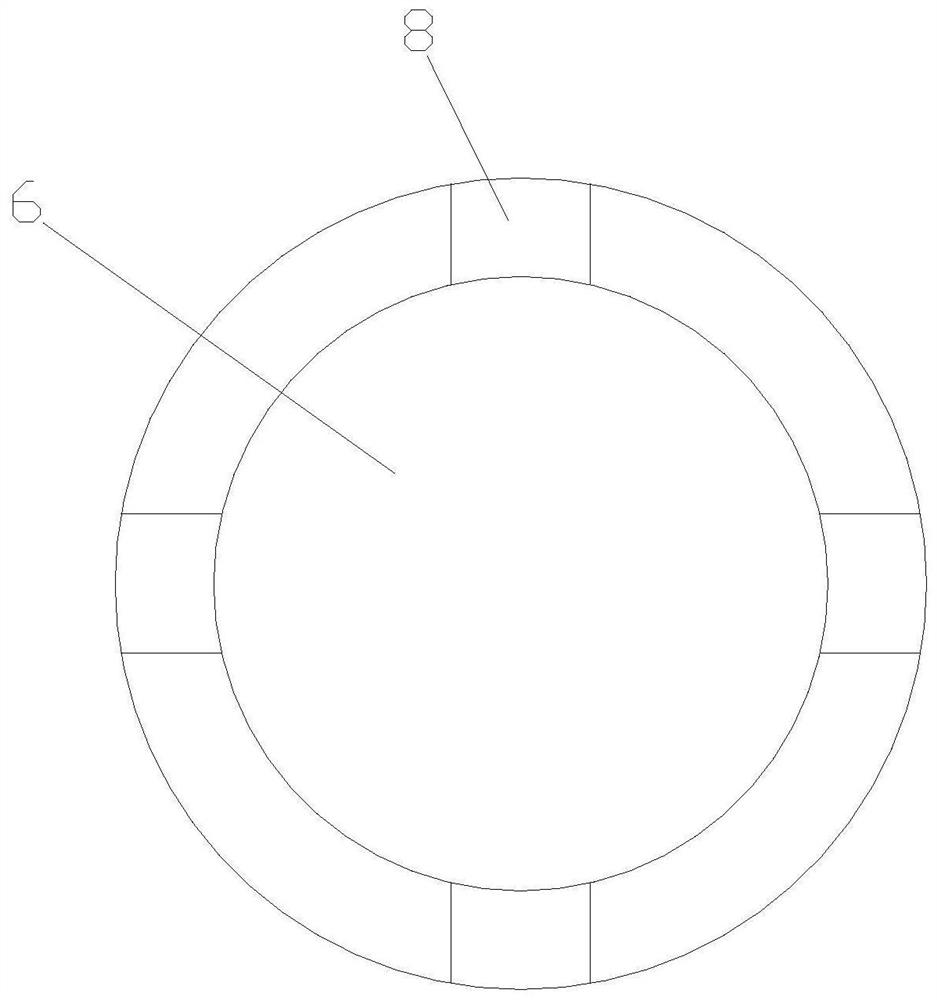

[0031]In this embodiment, the center sleeve 4 is provided with an insertion hole 6 matched with the center point 5, and a rotating bearing 7 is arranged in the insertion hole 6, and the outer ring of the rotation bearing 7 is connected to the center sleeve 4. The connection is detachable, and the inner ring of the rotating bearing 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com