Three-phase separator

A three-phase separator and shell technology, applied in the field of water treatment, can solve the problems of difficulty in performing their own duties, the sludge cannot reach the optimal sludge age, and the efficiency discount of anaerobic-anoxic-aerobic process, etc. High efficiency, avoid the effect of sludge discharge contradiction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

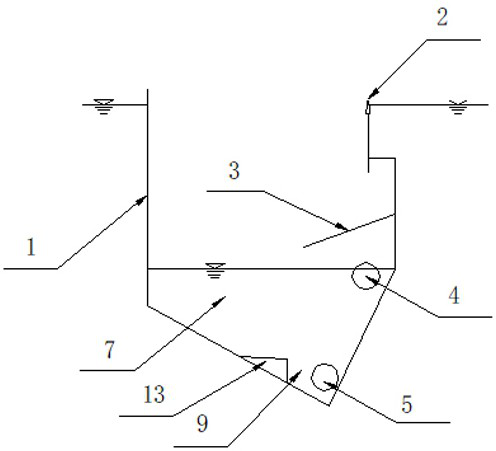

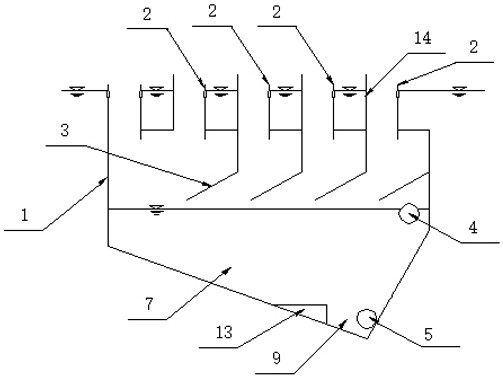

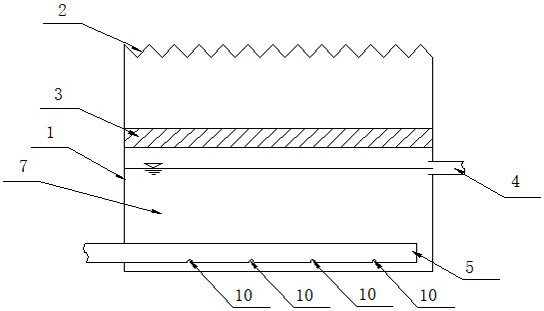

[0020] Embodiment: A three-phase separator, comprising a casing 1, a water drop weir 2, a water drop baffle 3, an outlet pipe 4 and a sludge return pipe 5, the casing 1 is a barrel structure with an open upper end and a closed bottom end, and the outer casing 1. The bottom surface forms a pointed bottom structure with a gradually shrinking cross-section. At least one drop weir 2 is fixedly installed on the inner wall of the opening of the shell 1. At least one drop baffle 3 is fixedly installed on the inner wall of the shell 1. The drop baffle 3 is set in an inclined state, each drop baffle 3 is located directly below the drop weir 2, and the sewage 6 that enters the shell 1 through each drop dam 2 falls to the surface of the drop baffle 3 and then bends back at the set angle and flows into it. At the bottom of the inner side of the housing 1, the outlet pipe 4 and the sludge return pipe 5 are fixedly installed on the housing 1. The water inlet of the outlet pipe is located und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com