Special cement-based self-leveling mortar for indoor floor heating and preparation method thereof

A self-leveling mortar and cement-based technology, applied in the field of architectural paint production, can solve the problems of large heat loss, low thermal conductivity and slow thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

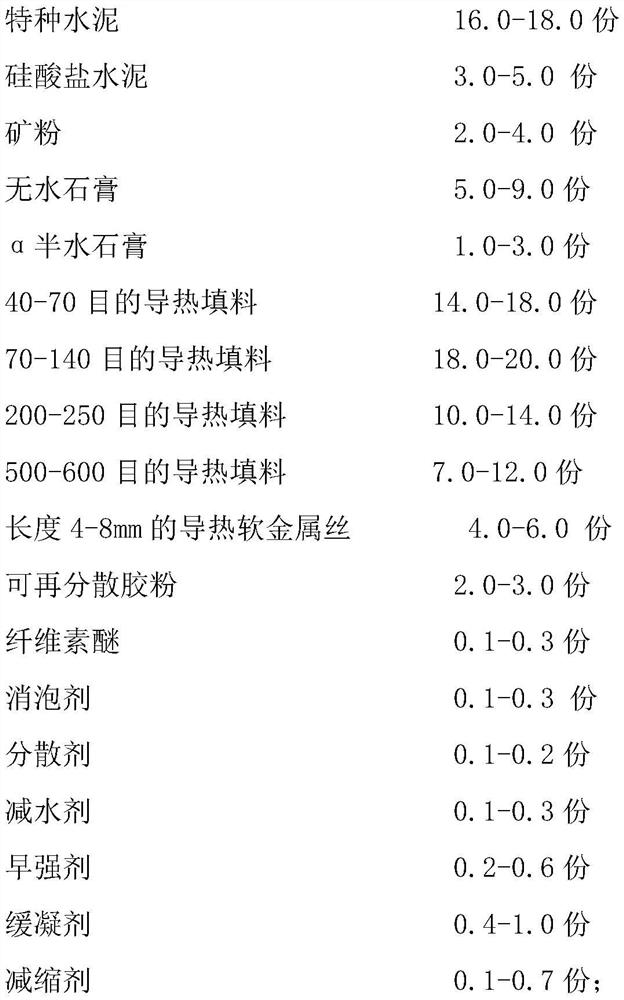

[0042] A special cement-based self-leveling mortar for indoor floor heating according to the present invention is prepared by mixing powder and water according to the mass ratio of 1:0.23; wherein, the powder is prepared from the following components according to the following weight ratio become:

[0043]

[0044] Wherein, the special cement is aluminate cement, the thermal conductivity of thermal conductive fillers of various meshes is 30-200w / m.k, and the thermal conductivity of the thermal conductive soft metal wire is 300-500w / m.k.

[0045] The thermally conductive fillers of various meshes are ceramic microspheres prepared from aluminum nitride.

[0046] The aluminate cement is high alumina cement.

[0047] The redispersible rubber powder is vinyl acetate-ethylene copolymer rubber powder, and the cellulose ether is hydroxypropyl methylcellulose.

[0048] The defoamer is a polyether dry powder defoamer, the dispersant is a modified fat derivative, the water reducer is ...

Embodiment 2

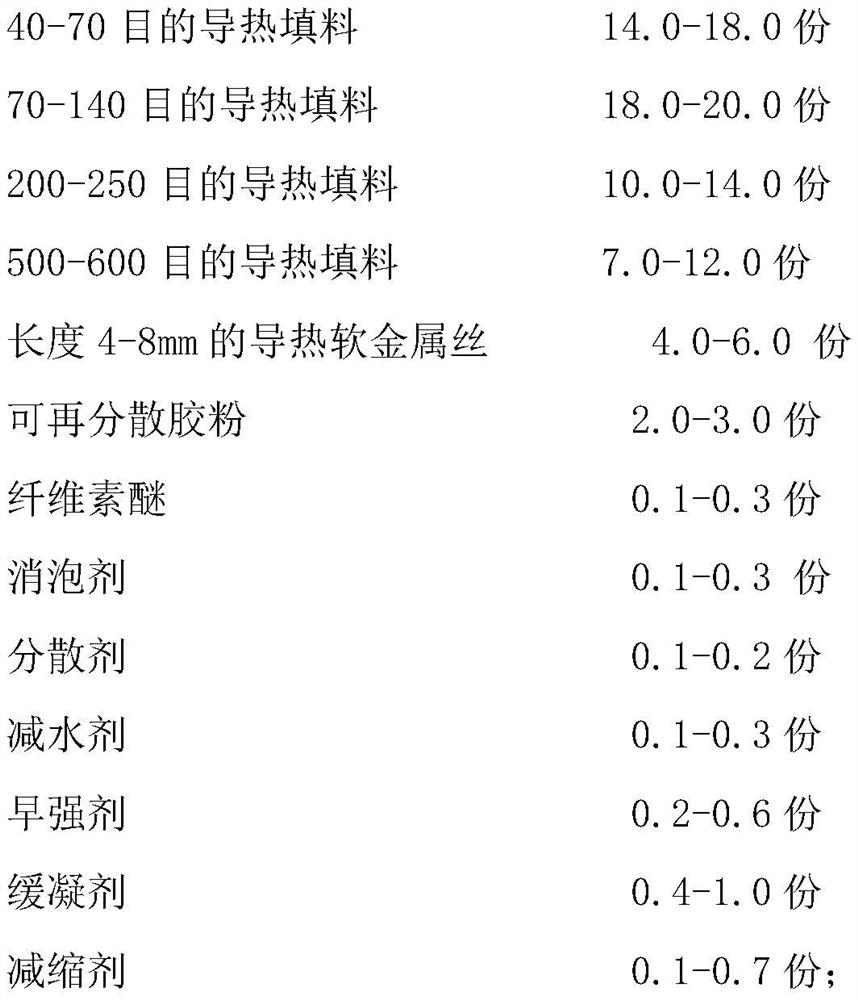

[0056] A special cement-based self-leveling mortar for indoor floor heating according to the present invention is prepared by mixing powder and water in a mass ratio of 1:0.22; wherein, the powder is prepared from the following components according to the following weight ratio become:

[0057]

[0058] Wherein, the special cement is aluminate cement, the thermal conductivity of thermal conductive fillers of various meshes is 30-200w / m.k, and the thermal conductivity of the thermal conductive soft metal wire is 300-500w / m.k.

[0059] The thermally conductive fillers of various meshes are ceramic microspheres prepared from alumina.

[0060] The heat-conducting soft metal wire is a heat-conducting soft aluminum wire.

[0061] The preparation method of the cement-based self-leveling mortar special for indoor floor heating mainly includes the following steps in sequence:

[0062] (1) Mix the cellulose ether, redispersible rubber powder, defoamer, dispersant, water reducer, ea...

Embodiment 3

[0067] A special cement-based self-leveling mortar for indoor floor heating according to the present invention is prepared by mixing powder and water at a mass ratio of 1:0.25; wherein, the powder is prepared from the following components according to the following weight ratio become:

[0068]

[0069]

[0070] Wherein, the special cement is aluminate cement, the thermal conductivity of thermal conductive fillers of various meshes is 30-200w / m.k, and the thermal conductivity of the thermal conductive soft metal wire is 300-500w / m.k.

[0071] The thermally conductive fillers of various meshes are ceramic microbeads prepared from boron nitride.

[0072] The heat-conducting soft metal wire is a heat-conducting soft silver wire.

[0073] The preparation method of the cement-based self-leveling mortar special for indoor floor heating mainly includes the following steps in sequence:

[0074] (1) Mix the cellulose ether, redispersible rubber powder, defoamer, dispersant, wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com