Recycled polycrystalline silicon ingot casting process based on layered charging mode

A polysilicon, layered technology, applied in the direction of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve problems such as being unfavorable to improve the quality of silicon ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments.

[0021] This embodiment is based on the regeneration polysilicon ingot process of layered charging mode, and the steps are as follows:

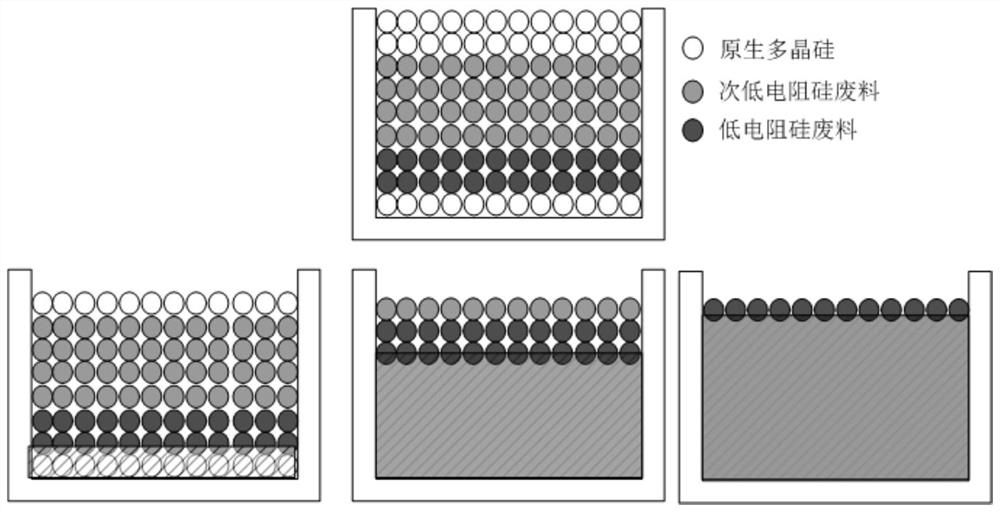

[0022] Step 1, laying a native polysilicon layer on the bottom of the crucible;

[0023] Step 2. Lay multiple layers of silicon waste on the native polysilicon layer. The silicon waste layers are arranged from bottom to top according to the grade of silicon waste from low to high. The grade of silicon waste is divided according to the average resistivity of silicon waste. The lower the average rate, the lower the grade of silicon waste;

[0024] Step 3, laying a layer of native polysilicon layer on the top;

[0025] Step 4, heating the ingot.

[0026] Among them, the classification method of silicon waste grade is as follows:

[0027] Pulverize polysilicon waste from different batches and sources and put them into containers for mixing;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com