High-safety protection device for adding nitrogen into tank body

A nitrogen protection device and safety technology, applied in the direction of container discharge, gas treatment/storage purposes, gas/liquid distribution and storage, etc., can solve the problems of inability to perform heat insulation, nitrogen filtration and moisture absorption, etc., to achieve Easy to operate, strong practicability, and the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

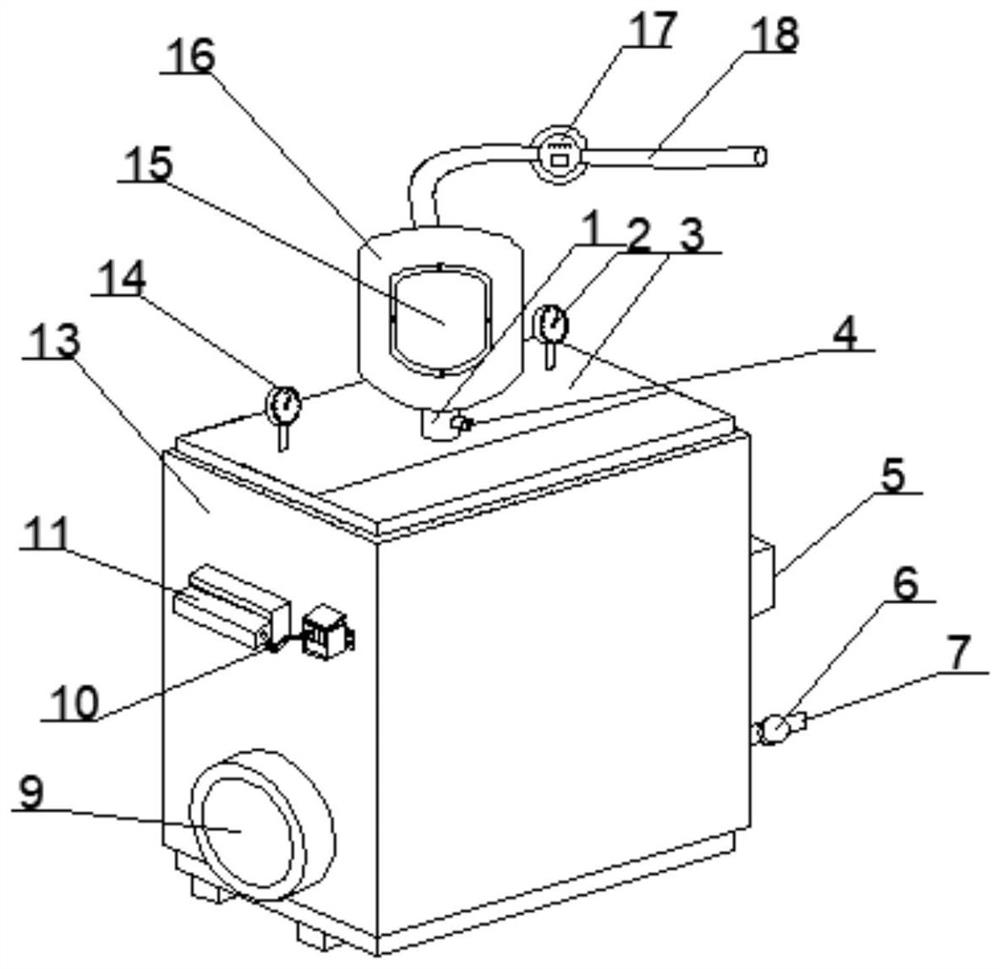

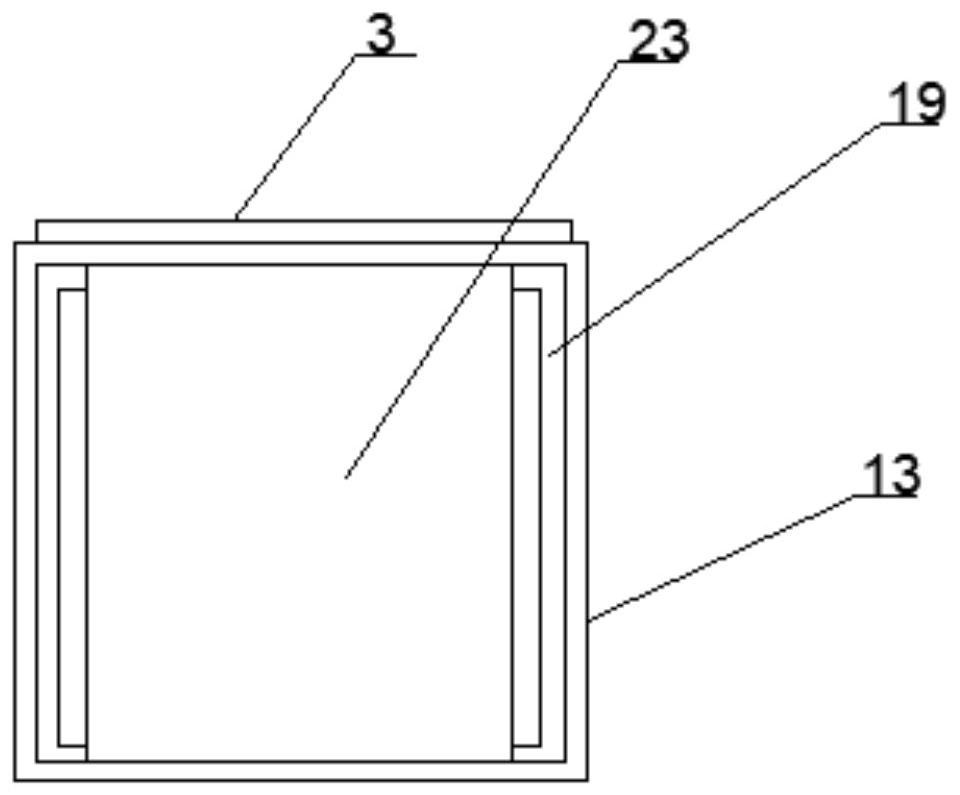

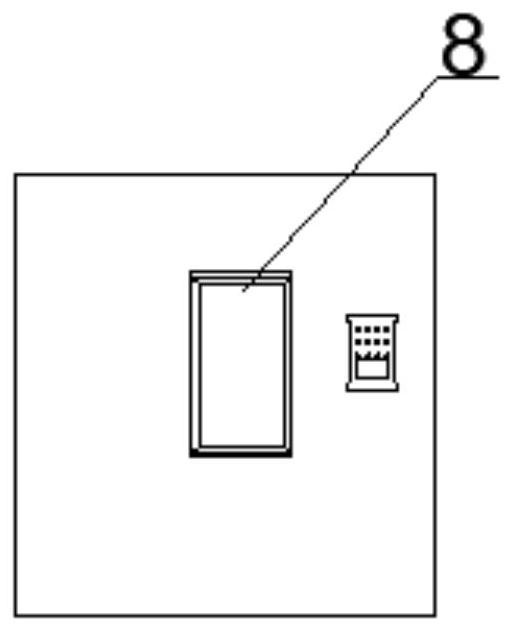

[0025] Such as Figure 1-5 As shown, a highly safe protection device for adding nitrogen gas to the tank body includes an outer protective case 13, an inner storage tank 23 and an enlarged pipe head 16, and one side of the outer protective case 13 is installed with an electric storage box 5 through screws. , one end of the storage box 5 is provided with a control box 8 through a positioning plate, an alarm 21 is installed in the control box 8 through a bolt, and a single-chip controller 22 is installed at one end of the alarm 21 through a bolt, and the outer The other side of the protective shell 13 is equipped with a semiconductor cooling chip 11 through the installation groove, and one end of the semiconductor cooling chip 11 is installed with a microcomputer time control switch 10 through a screw, and an inner storage tank 23 is arranged in the outer protective shell 13. A hollow interlayer 19 is arranged between the inner storage tank 23 and the outer protective shell 13, ...

Embodiment 2

[0038] Such as Figure 1-5As shown, a highly safe protection device for adding nitrogen gas to the tank body includes an outer protective case 13, an inner storage tank 23 and an enlarged pipe head 16, and one side of the outer protective case 13 is installed with an electric storage box 5 through screws. , one end of the storage box 5 is provided with a control box 8 through a positioning plate, an alarm 21 is installed in the control box 8 through a bolt, and a single-chip controller 22 is installed at one end of the alarm 21 through a bolt, and the outer The other side of the protective shell 13 is equipped with a semiconductor cooling chip 11 through the installation groove, and one end of the semiconductor cooling chip 11 is installed with a microcomputer time control switch 10 through a screw, and an inner storage tank 23 is arranged in the outer protective shell 13. A hollow interlayer 19 is arranged between the inner storage tank 23 and the outer protective shell 13, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com