Combined micro-channel structure

A technology of microchannel structure and channel structure, which is applied in the direction of fixed tubular conduit components, heat exchange equipment, heat exchanger types, etc., can solve the problems that the heat dissipation performance cannot be fully utilized, the network structure is complicated, and the complexity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0027] Such as figure 1 As shown, this example discloses a combined microchannel structure including a Y-shaped structure and a multi-square unit structure.

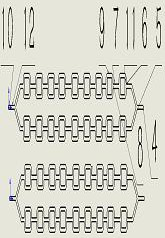

[0028] Such as image 3 Shown, described microchannel structure comprises: microchannel inlet 4, microchannel outlet 10, and some units 9, and described microchannel entrance and exit are Y-shaped, and described several units 9 are square, and the port of structure Y type is all provided with In the opening, several units 9 are first connected in sequence, and together with the Y-shaped entrance and exit constitute the microchannel stated in the present invention.

[0029] Such as image 3 As shown, the long midpoint 8 of one side of the square microchannel matches the rectangular channel 7 and is completely overlapped and connected. By analogy, the long midpoint of one side of the square microchannel w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com