Enhanced conductive paste and electronic device

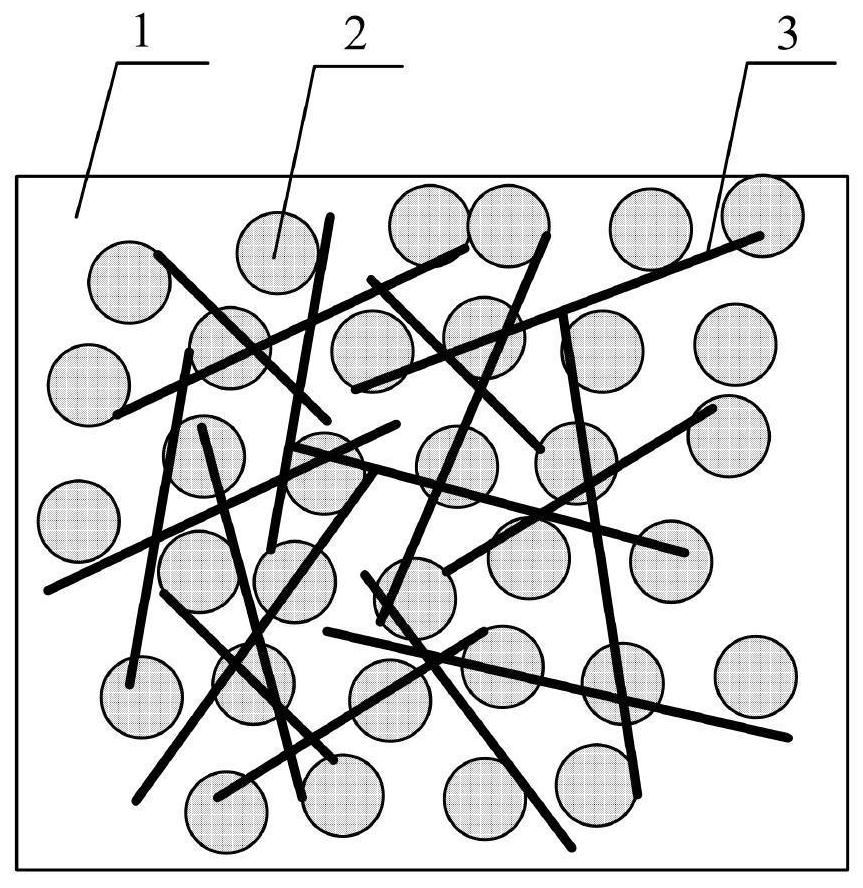

A conductive paste, enhanced technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of substrate shedding, limited application, poor substrate adhesion, etc., and achieve the goal of improving adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Optionally, the method for preparing the enhanced conductive paste in the embodiment of the present invention may include the following steps:

[0052] Step S1, preparing reinforcing filler;

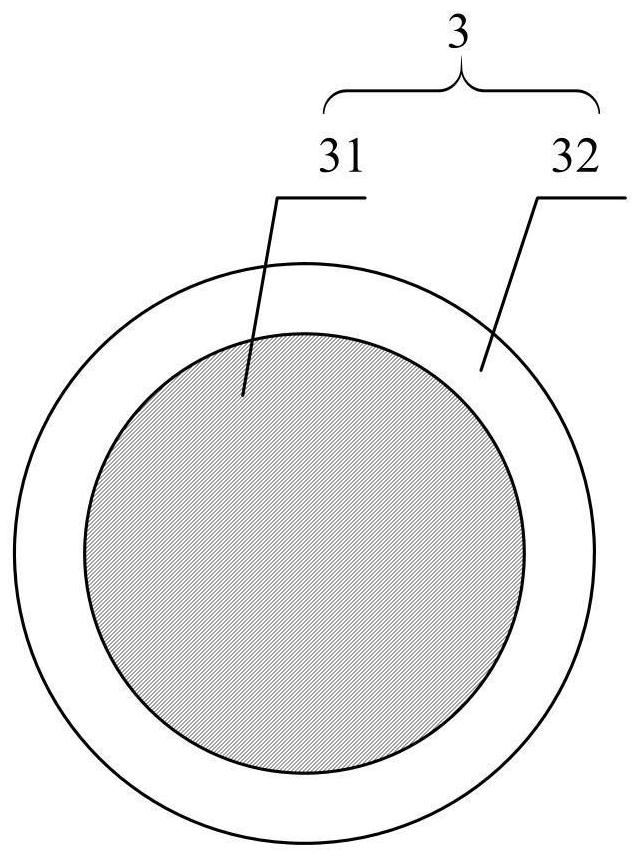

[0053] In one example, the reinforcing structure in the reinforcing filler is carbon fiber, and the metal layer is a silver layer. The preparation process of the reinforcing filler includes: grinding carbon fiber filaments or chopped strands by ball milling and then sieving, degumming, removing Oil, roughening, sensitization, activation, chemical silver plating, surface coating anti-oxidation layer and other links.

[0054] In another example, the reinforcing structure in the reinforcing filler is silicon carbide whisker, the metal layer is a silver layer, and the preparation process of the reinforcing filler includes: roughening, sensitization, activation, electroless silver plating, surface coating anti-oxidation layer, etc. link.

[0055] Of course, if the reinforcing structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com