Livestock breeding feed mixing device capable of cleaning residual feed on inner wall and using method

A technology of mixing device and feed, applied in the field of livestock breeding, can solve the problem of bacterial growth and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

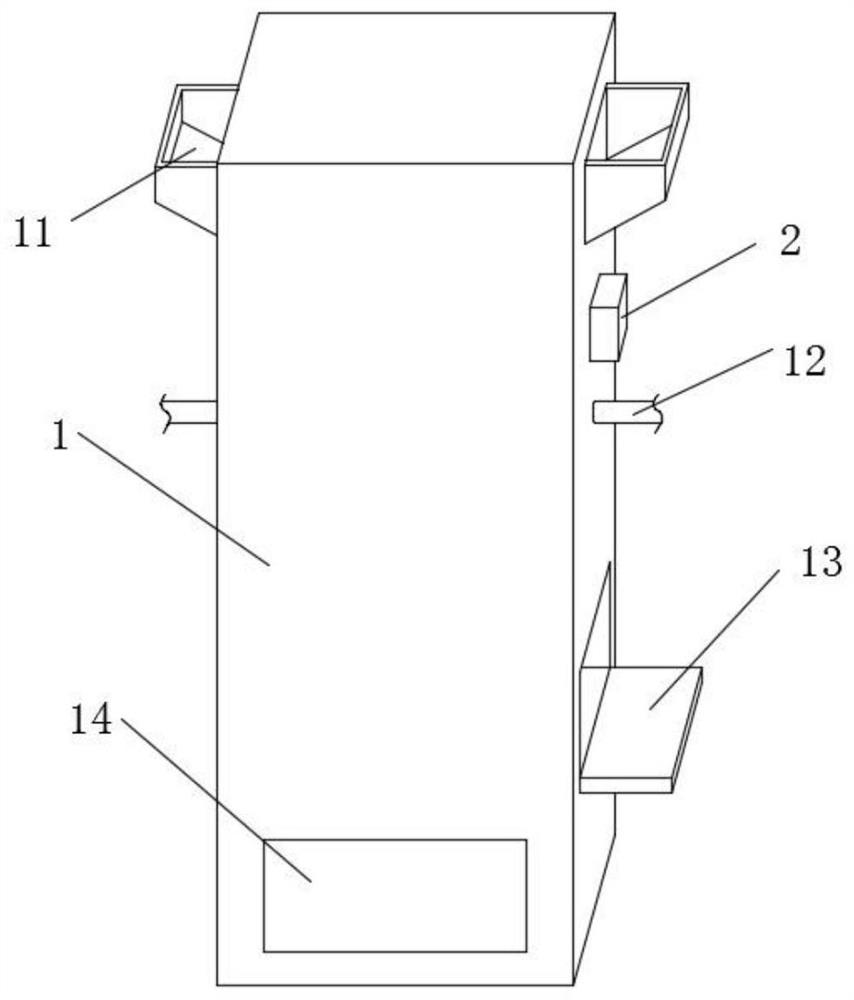

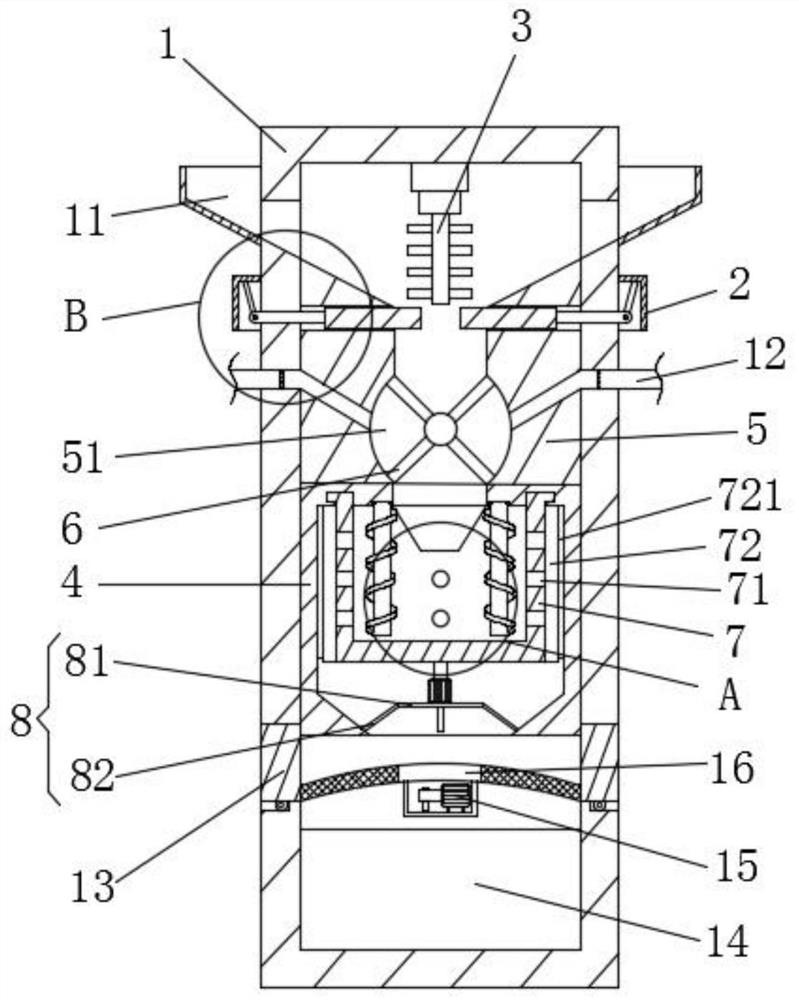

[0024] see Figure 1-3 and Figure 5 , the present embodiment provides a poultry breeding feed mixing device capable of cleaning up residual feed on the inner wall and a method of use thereof, including a feed mixing box 1, and feeding hoppers 11 are arranged on both sides of the feed mixing box 1, so that grass and straw can pass through the feeding hopper 11 Mix in a certain proportion.

[0025] A symmetrically arranged material guide block 5 is fixedly installed above the inner cavity of the feed mixing box 1 to guide and transport the raw materials conveyed on the feeding hopper 11. The top wall of the inner cavity of the feed mixing box 1 is connected with a crushing roller 3 through the rotation of the first motor. The raw materials are crushed to facilitate the mixing between grass and straw in the next step and play a pretreatment role.

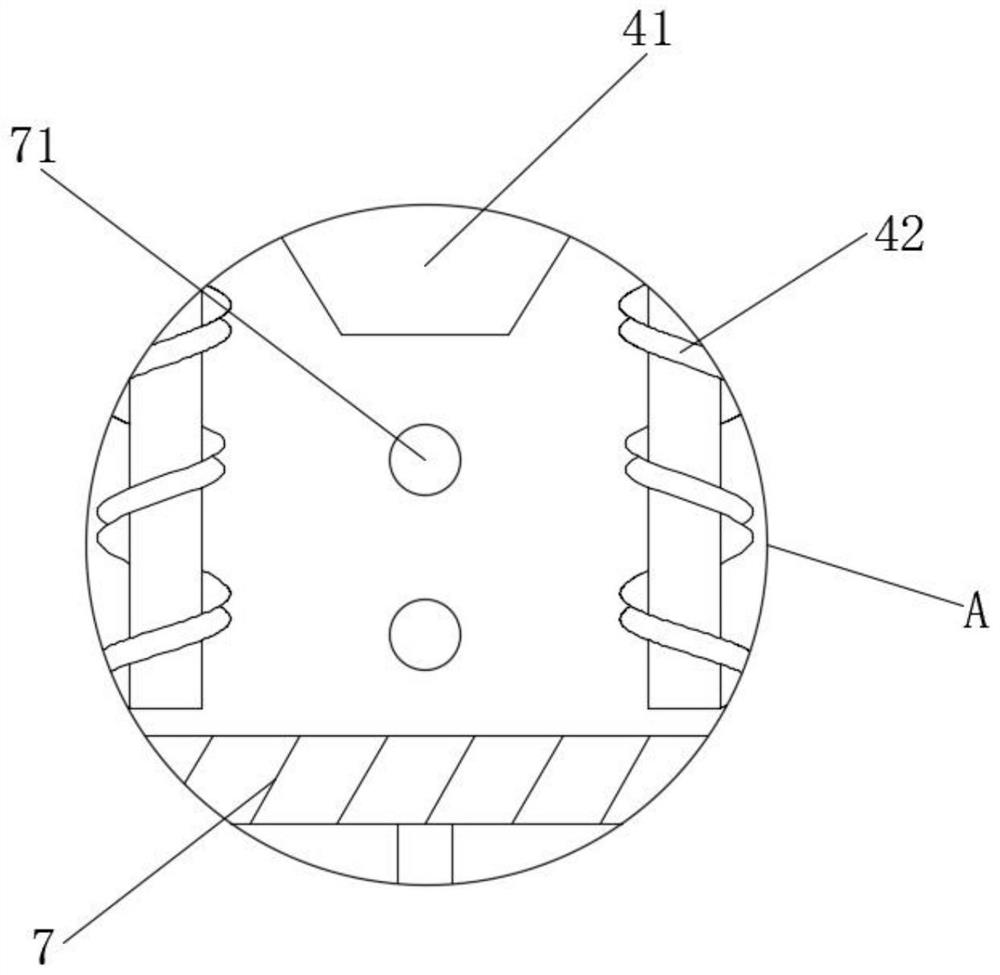

[0026] The middle part of the inner cavity of the feed mixing box 1 is fixedly installed with a mixing cylinder 4 with openings up...

Embodiment 2

[0039] see figure 2 , made further improvement on the basis of embodiment 1: in order to prevent the situation of clogging caused by the accumulation of feed, the middle part of the inner cavity of the feed mixing box 1 is rotated and installed with a fixed column, and the outer wall of the fixed column is fixedly equipped with a plurality of disturbance plates 6, through The fixed column drives the disturbance plate 6 to rotate to transport the feed material.

[0040] The sides of the two guide blocks 5 that are close to each other are provided with an arc-shaped groove 51 that matches the disturbance plate 6, and a feeding chamber is formed between two adjacent disturbance plates 6 and the arc-shaped groove 51, and the pulverized feed is It is divided into multiple feeding chambers for conveying, effectively avoiding the accumulation of feed materials, and there will be certain bacterial growth in the long-term accumulation, which further improves the quality of feed produc...

Embodiment 3

[0045] see figure 2 with Figure 4 , made further improvements on the basis of Example 2: in order to facilitate the adjustment of the size of the feed crushing, the inside of the two guide blocks 5 are slidingly installed with baffles 9, and the sides of the two baffles 9 close to each other form a lower In the feed chamber, the sides of the two baffles 9 away from each other are fixedly equipped with a fixed rod, and the side of the fixed rod away from the baffle 9 is movably connected with a sliding block 2, and the sliding block 2 is slidably connected with the outer wall of the feed mixing box 1. The block 2 slides, so that the fixed rod drives the baffle 9 to slide, thereby changing the distance between the two baffles 9, and when the feed is crushed to a certain extent, it leaks from the feeding chamber, so as to process different kinds of poultry feed Particles, so the scope of application is wider.

[0046] The side where the sliding block 2 is in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com