Gene-edited tobacco one-way liquid-conveying and multi-plant automatic hydroponic device and method

A gene editing and hydroponic device technology, applied in the field of tobacco cultivation, can solve problems such as difficulty in observing the water level of nutrient solution, growth of green algae in hydroponics, cross infection of pathogens, etc., and achieves the effects of low equipment cost, prevention of cross infection and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

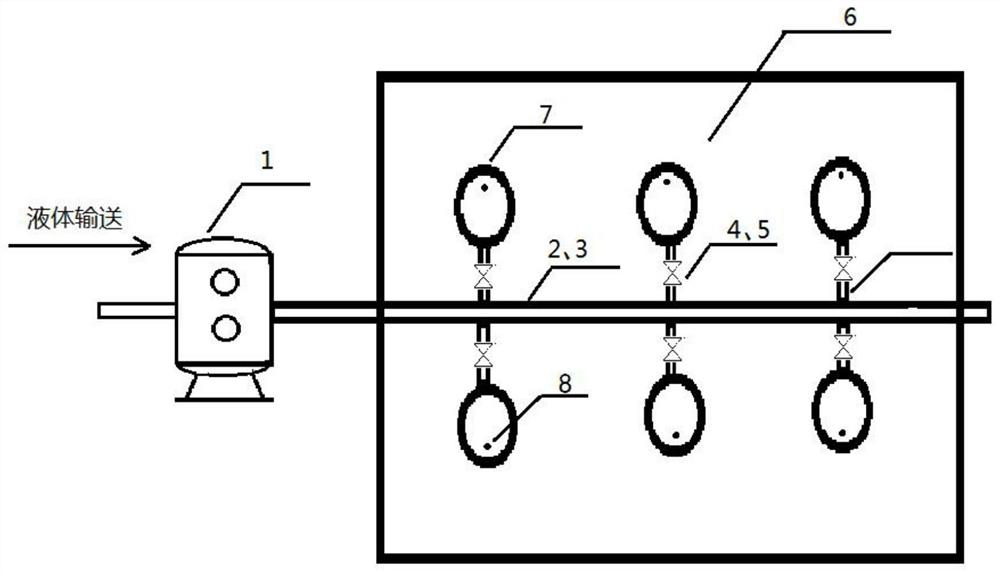

[0056] According to attached figure 1 Form an automatic nutrient solution delivery device.

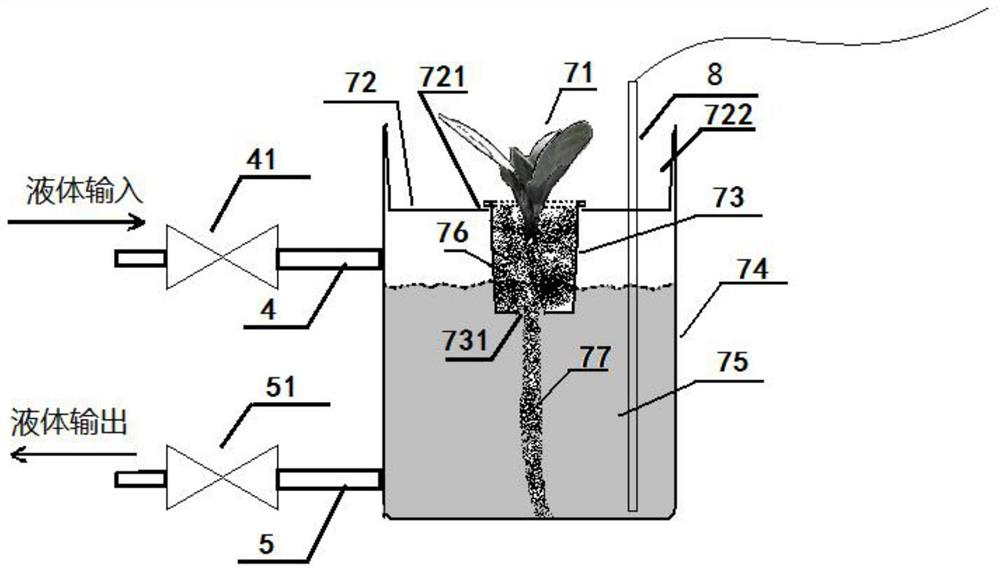

[0057] Single-plant hydroponic device: a shading hydroponic cup with a diameter of 8cm and a height of 10cm, the cup cover is concaved by 2cm; the diameter of the planting cup is 5cm, the height is 5cm, and the diameter of the fixed edge of the planting cup is 0.5cm larger than that of the hydroponic cup, and it can bear weight More than 2kg in weight. The height of the nutrient solution was set to 8cm.

[0058] The gene-edited tobacco and the female parent control tobacco were raised in normal floating. After the tobacco seedlings reached the standard of normal transplanting and strong seedlings, 20 tobacco seedlings with uniform growth and uniform size were selected for transplanting. When transplanting, pull out the tobacco seedlings from the seedling tray, wrap the tobacco roots with black polyester fiber (wrapped together with the seedling growth substrate attached to the roots)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com