Method for cleaning micro-nano particles through shock waves induced by spatially constrained double-beam laser

A micro-nano particle, laser-induced technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of small cleaning area and low cleaning efficiency, achieve enlarged cleaning area, convenient control, and avoid direct interaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

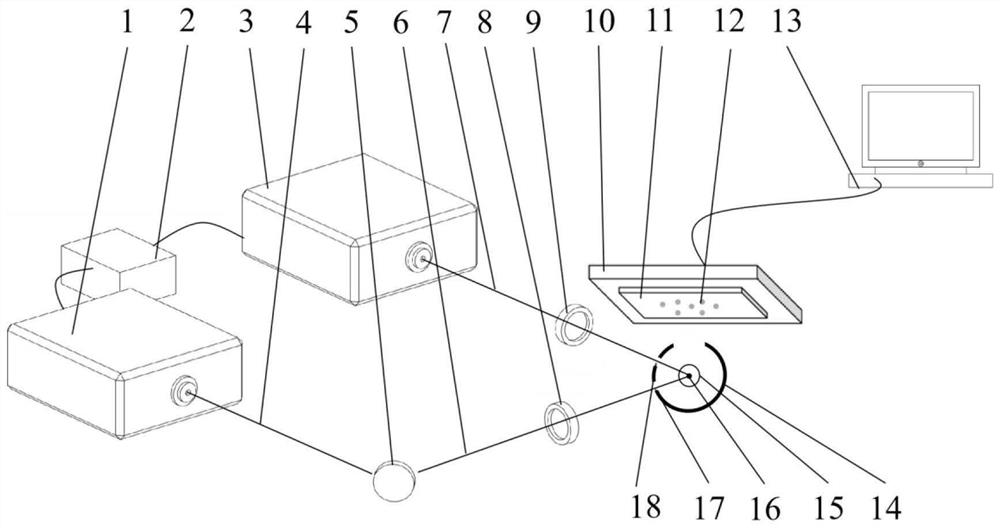

[0025] refer to figure 1 , a space-constrained double-beam laser-induced shock wave cleaning method for micro-nano particles, the method comprising the following steps:

[0026] 1), bonding the substrate to be cleaned on the three-dimensional mobile platform 10, and moving the three-dimensional mobile platform 10 so that the substrate to be cleaned is located at the focal point of the laser pulse and at the exit of the cavity;

[0027] 2), using the first pulsed laser beam and the second pulsed laser beam to focus in the cavity to induce gas breakdown to generate a plasma shock wave, and the intensity of the shock wave is enhanced by reflection on the inner surface of the cavity, so that the micro-nano particle pollutants on the surface of the substrate to be cleaned Fly away from the surface of the substrate to be cleaned under the action of shock wave removal force....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com