Pressing mechanism for production of rolling type optical lenses

A technology of optical lenses and pressing mechanism, which is applied in optical components, applications, household appliances, etc. It can solve problems such as inability to discharge air, unstable force application, and large fluctuations, so as to ensure production quality and efficiency, and press-fitting process Smooth, accuracy-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

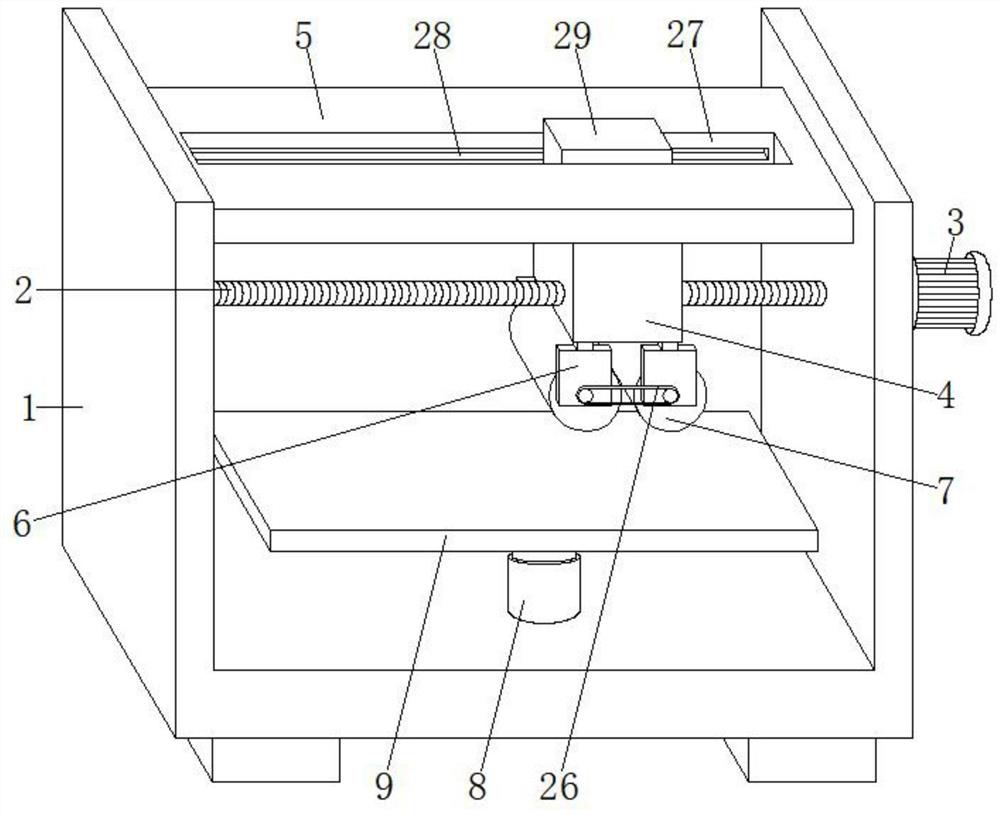

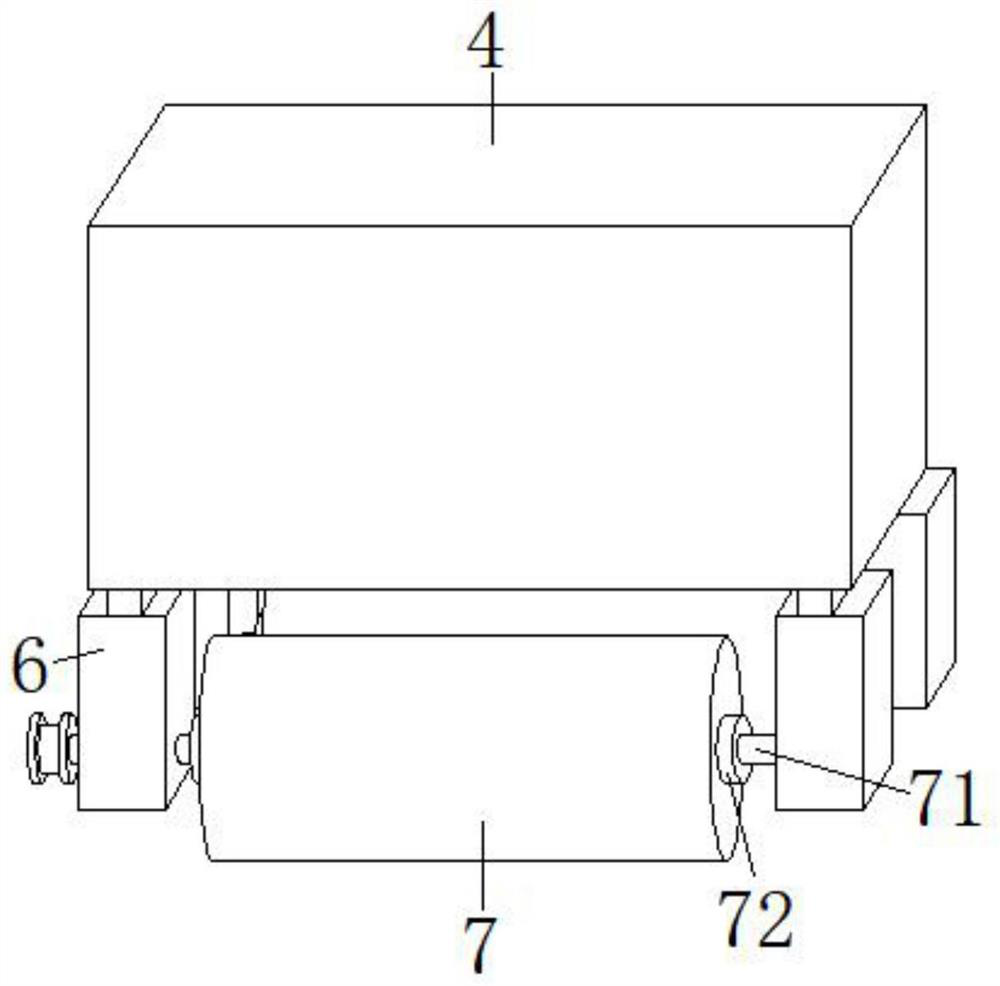

[0033] See Figure 1-5 The present invention provides a technical solution: a pressing mechanism for rolling optical lens production, including press table 1, press table 1 is a U-shaped table, and the inner wall of the pressing table 1 is rotatable to connect a screw 2 The side surface of the pressing table 1 is attached, and the output terminal of the stepping motor 3 is fixedly connected to the screw 2, and the screw 2 is applied to the shift roller 4, and the pressing table 1 is mounted on the press. The plate 5, and the shift roller seat 4 slides on the restricted plate 5, and the bottom of the shift roller 4 has two sets of positioning have two, and a set of positioning has two, and a set of positioning has a position. 6 Returning is mounted, the rolling roller 7 is mounted, and the inner bottom wall of the pressing table 1 is mounted with the automatic telescopic rod 8, and the top end of the automatic telescoping rod 8 is fixedly connected to the tape 9, and the end of the ...

Embodiment 2

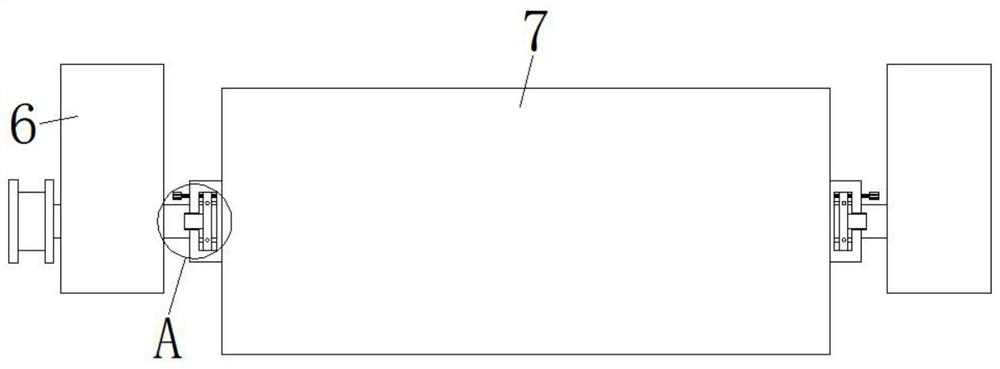

[0043] See figure 1 , 6 -9, and the first embodiment is that the branching mechanism includes a rotating ring 18, a magnetic block A19, a through hole 20, and a magnetic block B21, and the rotating ring 18 is rotated to the positioning tool 6, and the rotating shaft 71 is running through The rotating ring 18 is fixed to the side of the rotating ring 18 close to the side of the pellet 72, and the number of magnetic blocks A19 is two, and the two magnetic block A19 is close to the side of the bits 72. For the anisotropic magnetic pole, the sliding groove 10 is opened to the inner wall of the shaft 71 on the inner wall of the shaft 71, and the displacement plate 11 is fixed to the side of the shaft 71 fixed to the magnetic block B21 corresponding to the through hole 20, and a set of magnetic blocks A19 is respectively Block B21 magnetic phase suction and magnetic repellency.

[0044] The loop-shaped rail groove 22 is opened on the positioning 6, and the rotating ring 18 is fixed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com