Color-changing display warming paste and preparation method of color-changing coating

A warm paste and coating technology, applied in the field of personal care, can solve the problems of inability to achieve consumer perception, interactive effects, low temperature burns, and the inability to sense the rising temperature of the warm paste in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] According to a specific embodiment provided by the present invention, the weight percentage of the resin is: 0.01-8%, the weight percentage of the inorganic mineral powder is: 0.01-8%, and the weight percentage of the normal temperature volatile solvent is: 0-8%. 35%, the weight percentage of the moisture-absorbing inorganic salt is: 0-5%, and the balance is water.

[0033] According to a specific embodiment provided by the present invention, the weight percentage of the resin is: 0.1-5%, the weight percentage of the inorganic mineral powder is: 0.1-5%, and the weight percentage of the normal temperature volatile solvent is: 0.1-5%. 30%, the weight percentage of the moisture-absorbing inorganic salt is: 0.01-3%, and the balance is water.

[0034]According to a specific embodiment provided by the present invention, the resin is one or more of water-soluble phenolic resins, amino resins, alkyd resins, epoxy resins, and acrylic resins. The water-soluble phenolic resin, am...

specific Embodiment approach

[0036] According to a specific embodiment provided by the present invention, the moisture-absorbing inorganic salt is one or more of calcium chloride, magnesium chloride, and magnesium sulfate. Calcium chloride is a colorless cubic crystal, white or off-white, granular, honeycomb block, spherical, irregular granular, powder. It is highly hygroscopic and easily deliquesces when exposed to the air. Magnesium chloride is a colorless, bitter, water-soluble crystal with strong hygroscopicity. Magnesium sulfate is a commonly used chemical reagent and drying reagent. It is a colorless or white crystal or powder, odorless, bitter in taste, and deliquescent.

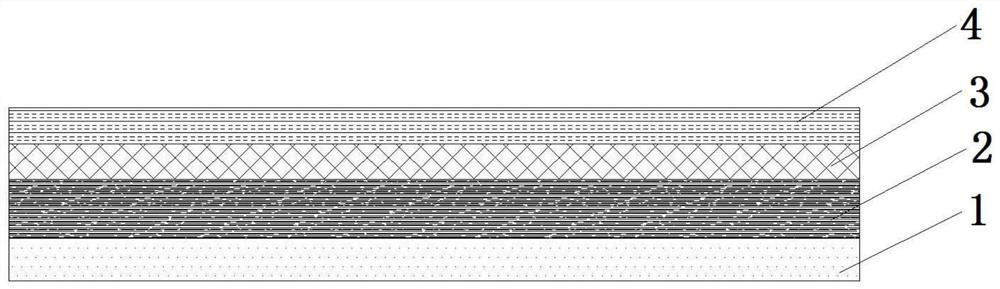

[0037] According to a specific embodiment provided by the invention, the inner packaging base material layer 3 is a non-woven fabric or a paper base material, and the non-woven fabric and paper base material are easy to be colored, and can be colored in different colors or designed according to different situations. Patterns, n...

Embodiment 1

[0048] The present embodiment provides the preparation method of described discoloration coating 4, comprises the following steps:

[0049] Step 1: Weighing the weight percentage and weighing the material, the weight of each component of the material is respectively: acrylic resin: 35g, calcium silicate: 50g, diethylene glycol butyl ether: 180g, water: 735g;

[0050] Step 2: Add water into the three-roll mill, start grinding, and the speed is 60rpm;

[0051] Step 3: Under stirring state, add weighed acrylic resin: 35g, calcium silicate: 50g, diethylene glycol butyl ether: 180g in order; grind all the above materials for 30min after adding;

[0052] Step 4: Stop stirring, separate the mixture from the grinder and store it in a sealed container;

[0053] Step 5: Apply the above-mentioned mixed material to the inner packaging substrate layer 3 made of non-woven fabric by 50-mesh screen printing;

[0054] Step 6: Air shower until the water evaporates, then seal and store.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com