Mask, preparation and application thereof

A mask plate and mask layer technology, which is applied in semiconductor/solid-state device manufacturing, vacuum evaporation plating, coating, etc., can solve the problem of gravity deformation of the mask plate, improve patterning accuracy, reduce shadow effect, high resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

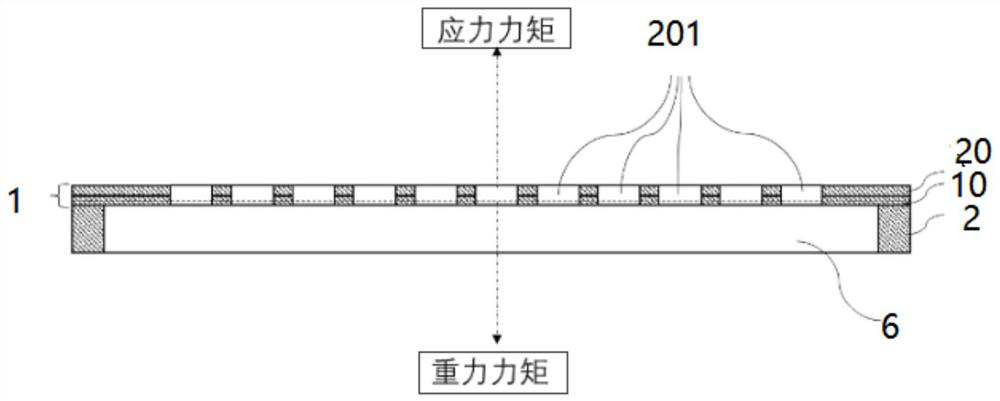

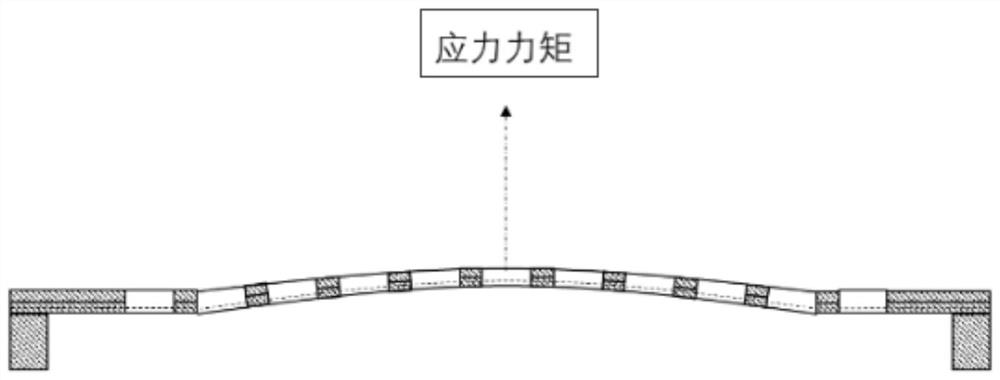

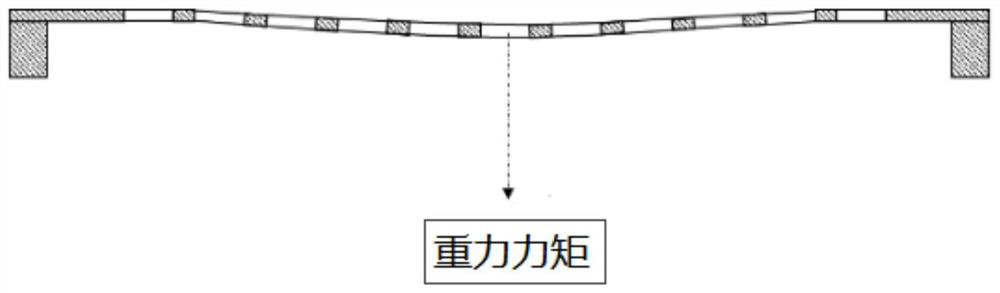

[0038] see Figure 1-3 Shown: a mask plate 1, which is an ultra-thin multi-layer structure film with a desired deposition pattern, and has a ring-shaped support frame 2 outside it, and the ring-shaped support frame 2 extends along the perimeter of the multi-layer structure.

[0039] The mask plate 1 includes at least two layers: a first mask layer 10 and a second mask layer 20 . Wherein the first mask layer 10 contains a first material with residual tensile stress, and the first material in this embodiment is silicon nitride. The second mask layer 20 contains a second material with residual compressive stress, and the second material in this embodiment is silicon dioxide. In addition, in order to directly pattern a dense pattern with a size less than 10 microns, the multilayer film of the mask plate 1 is very thin, and preferably has a thickness equal to or less than 1 micron. In this embodiment, the first mask layer 10 is 50 nm, and the remaining The tensile stress is 1 GPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com