Patents

Literature

37results about How to "Simplify the patterning process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

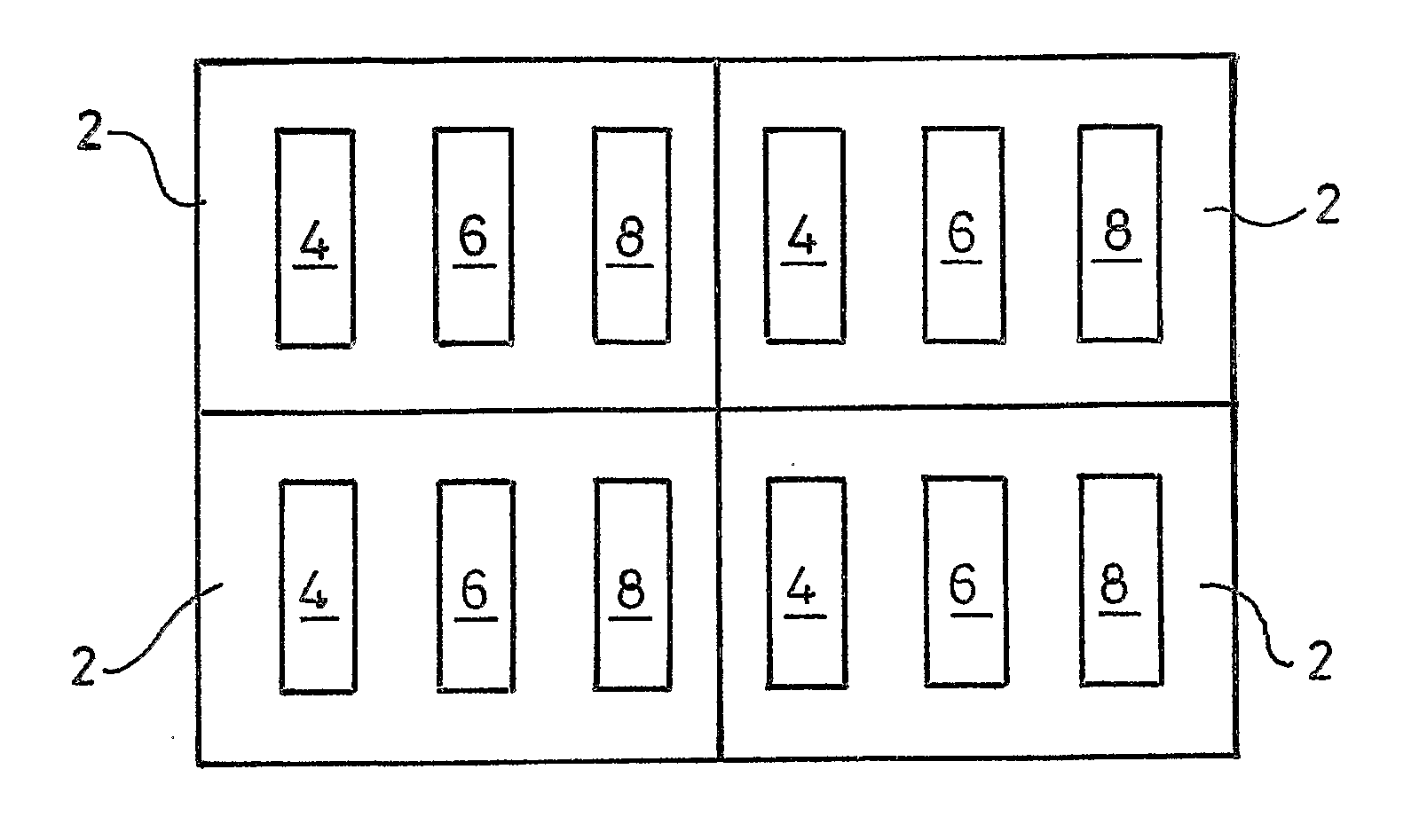

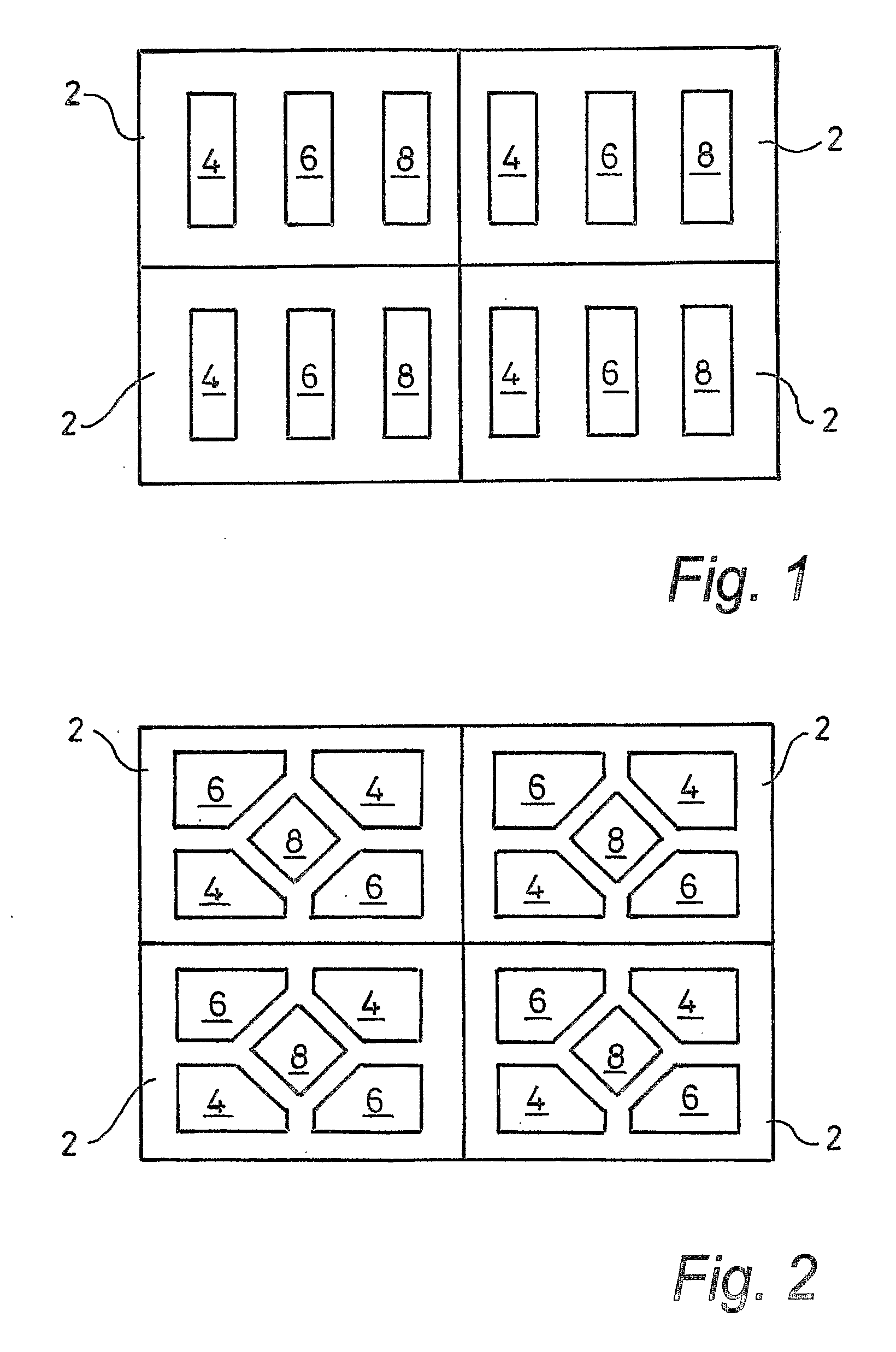

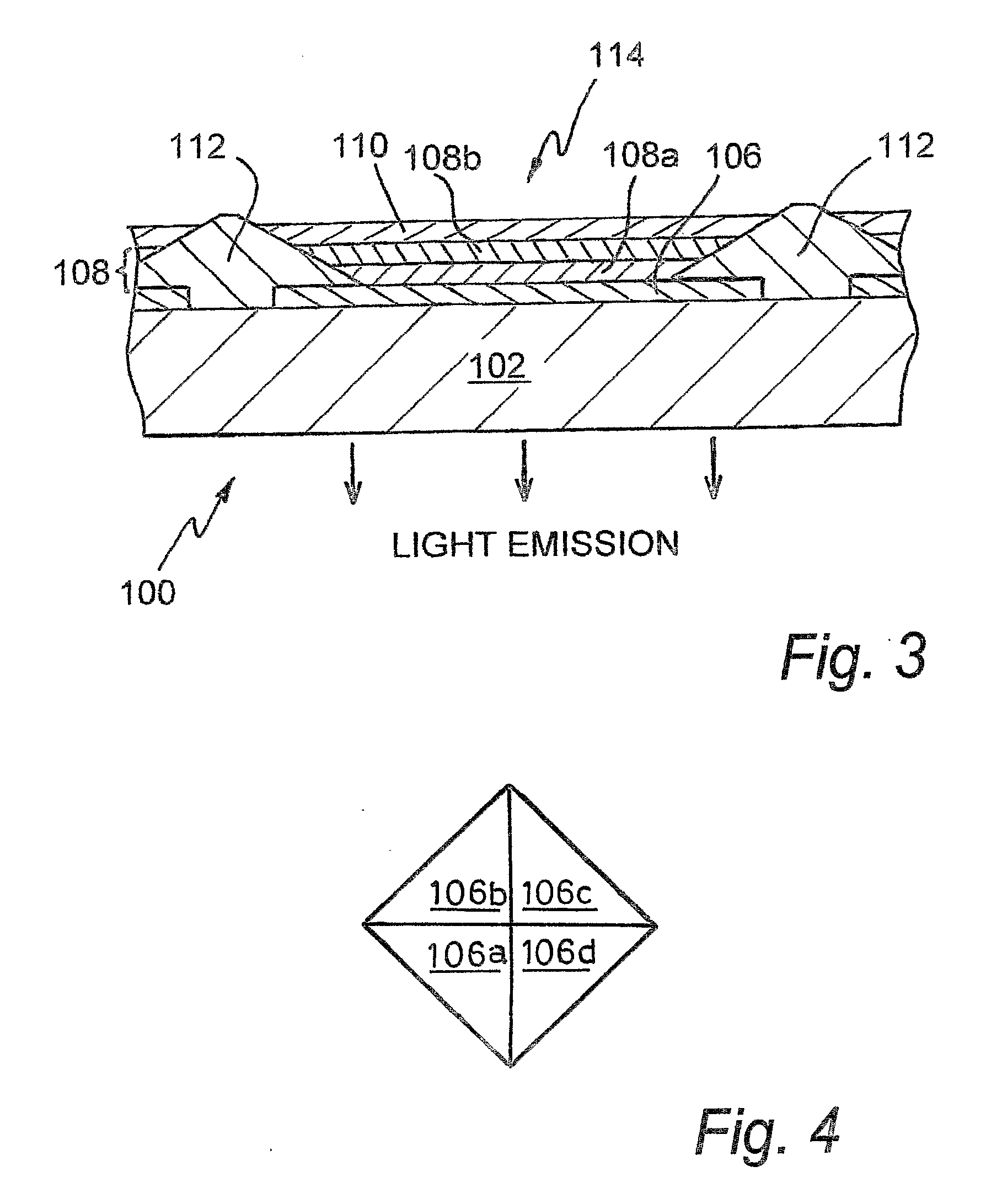

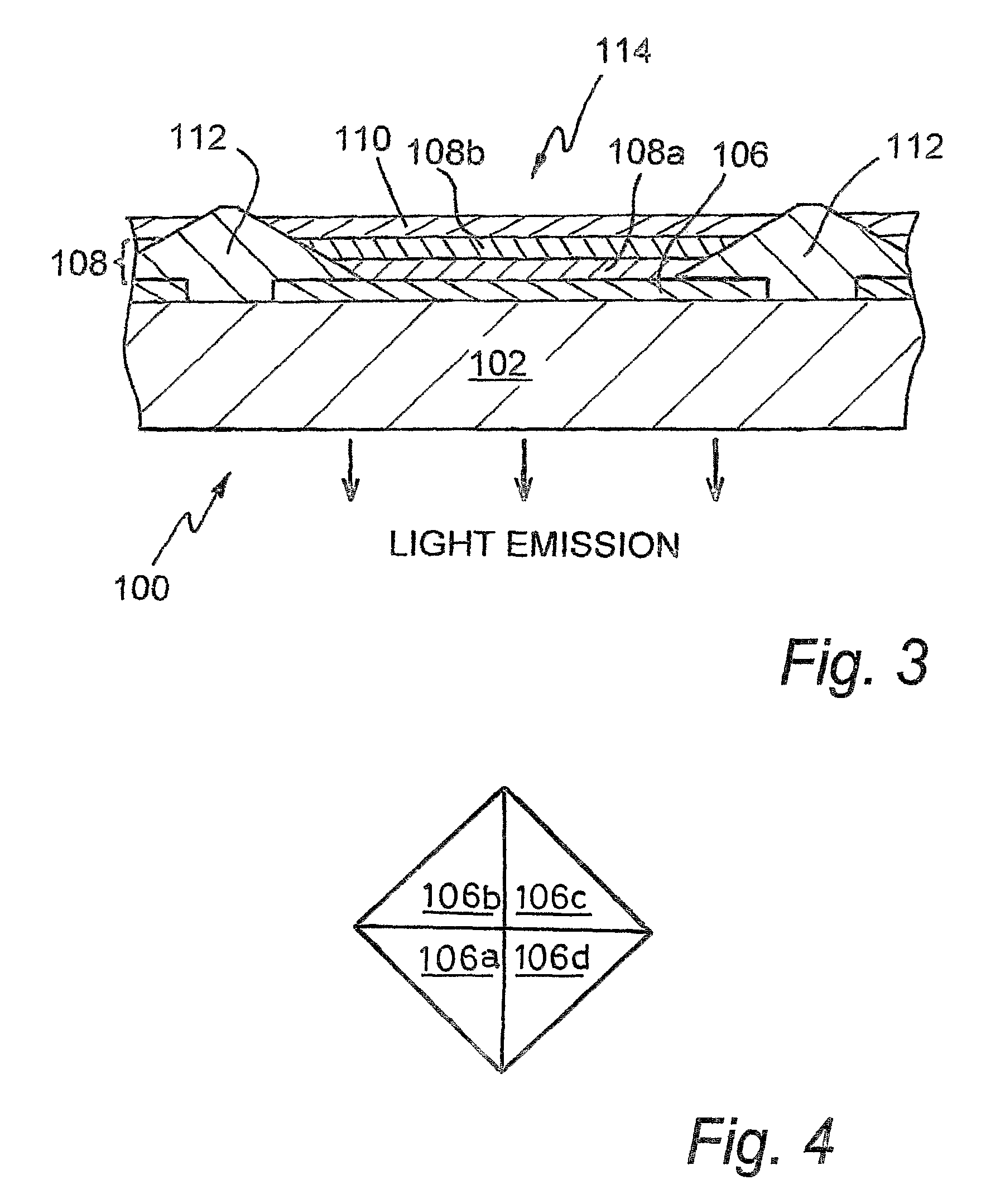

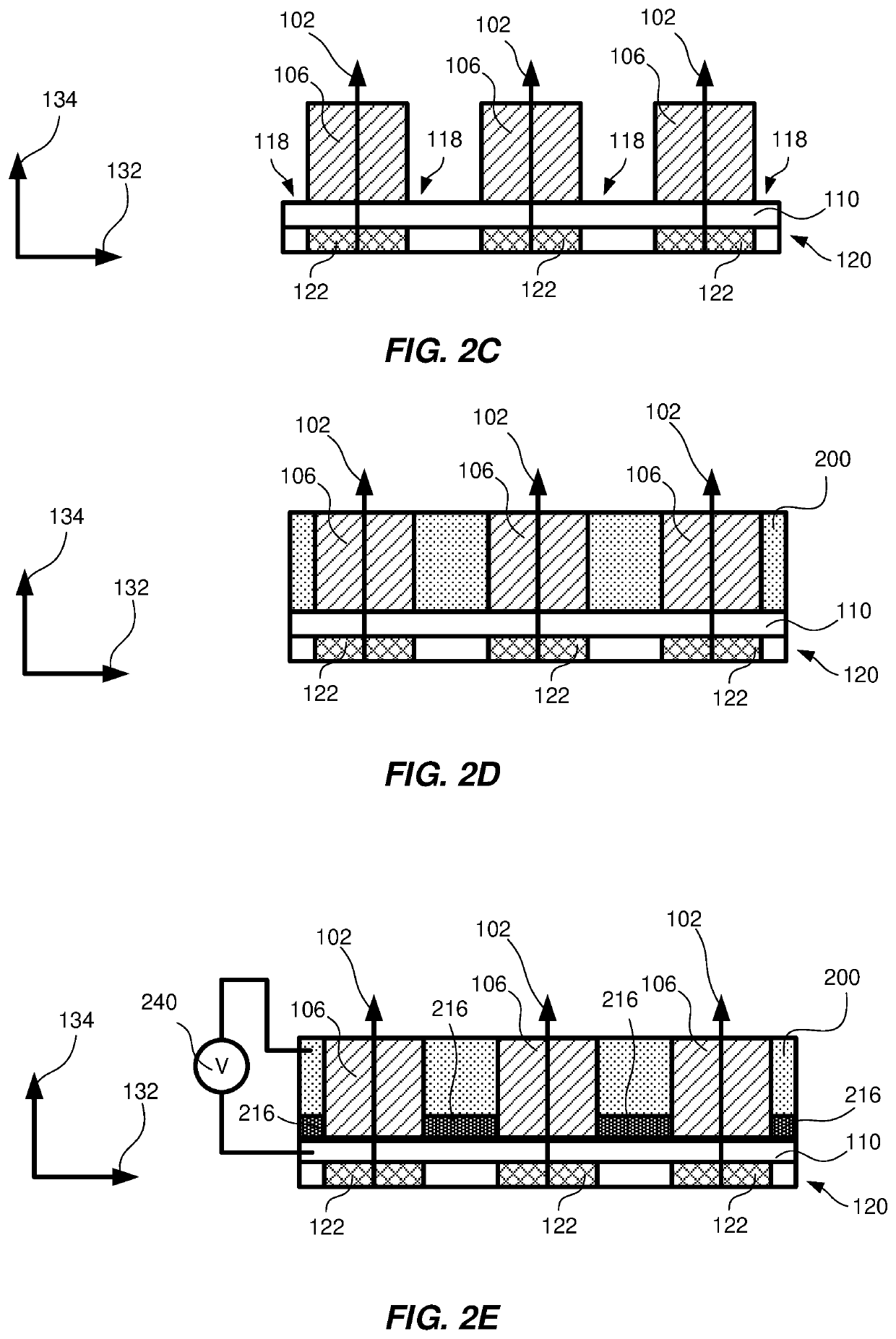

Optoelectronic display and method of manufacturing the same

ActiveUS20090302331A1Reduce tooling costsSimplify the patterning processDischarge tube luminescnet screensStatic indicating devicesDisplay deviceComputer science

Owner:CAMBRIDGE DISPLAY TECH LTD

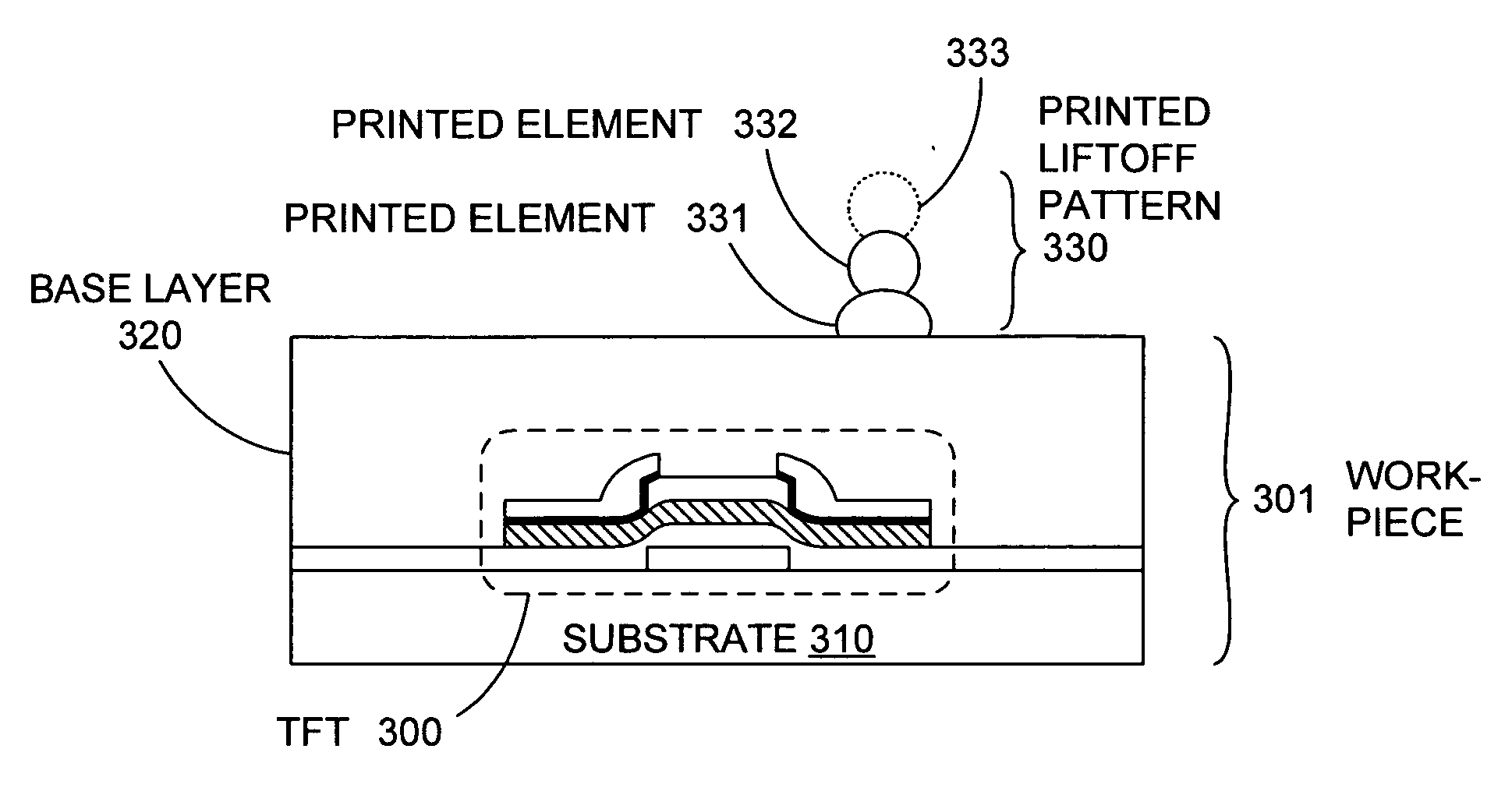

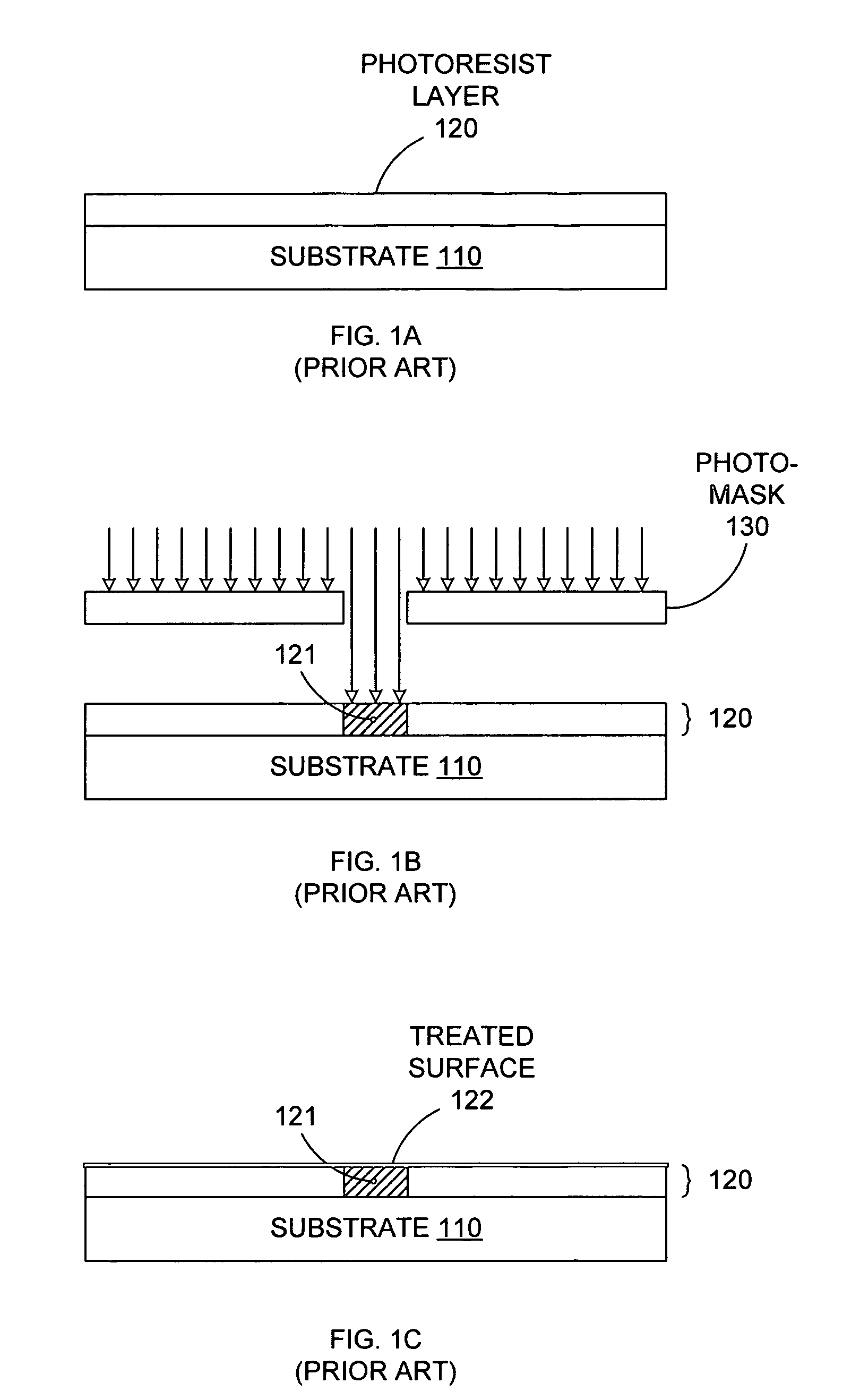

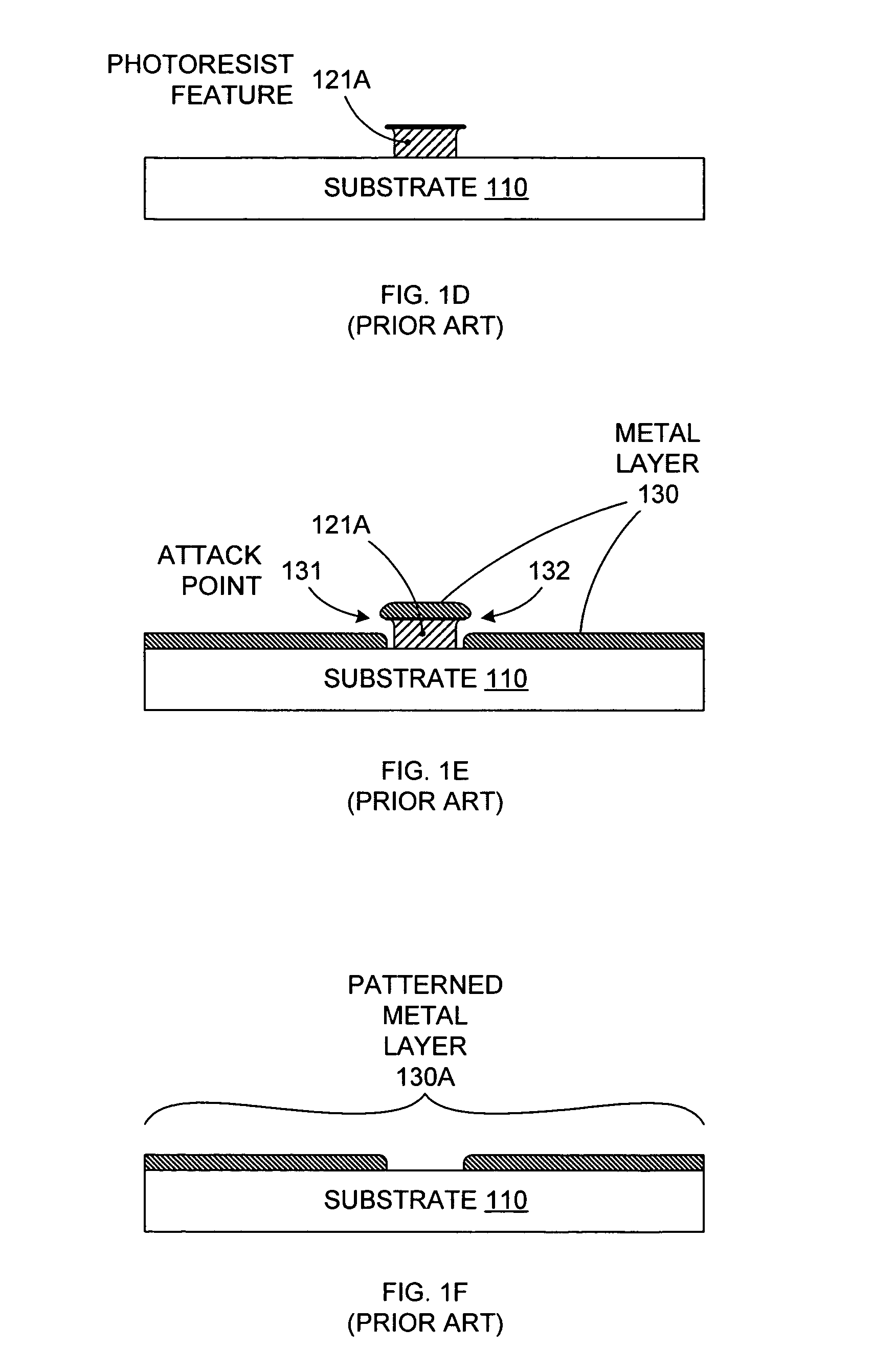

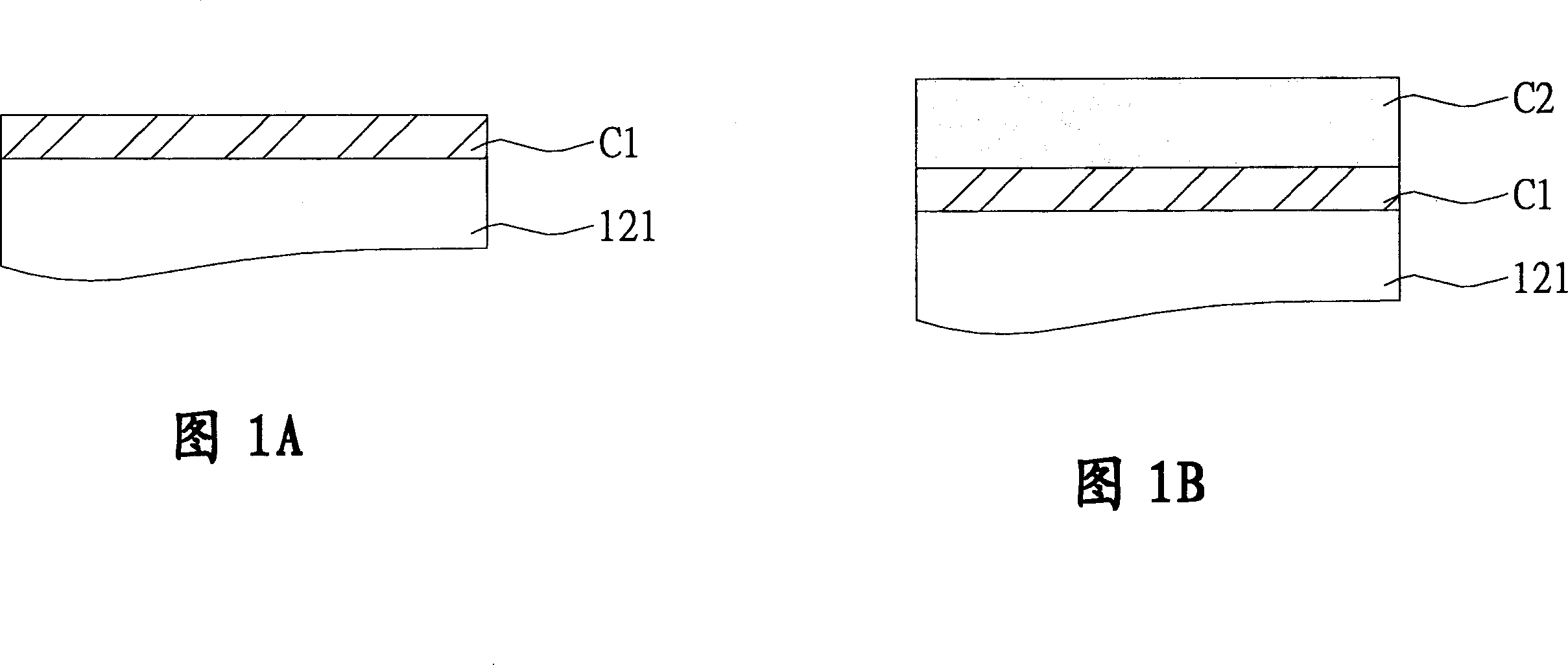

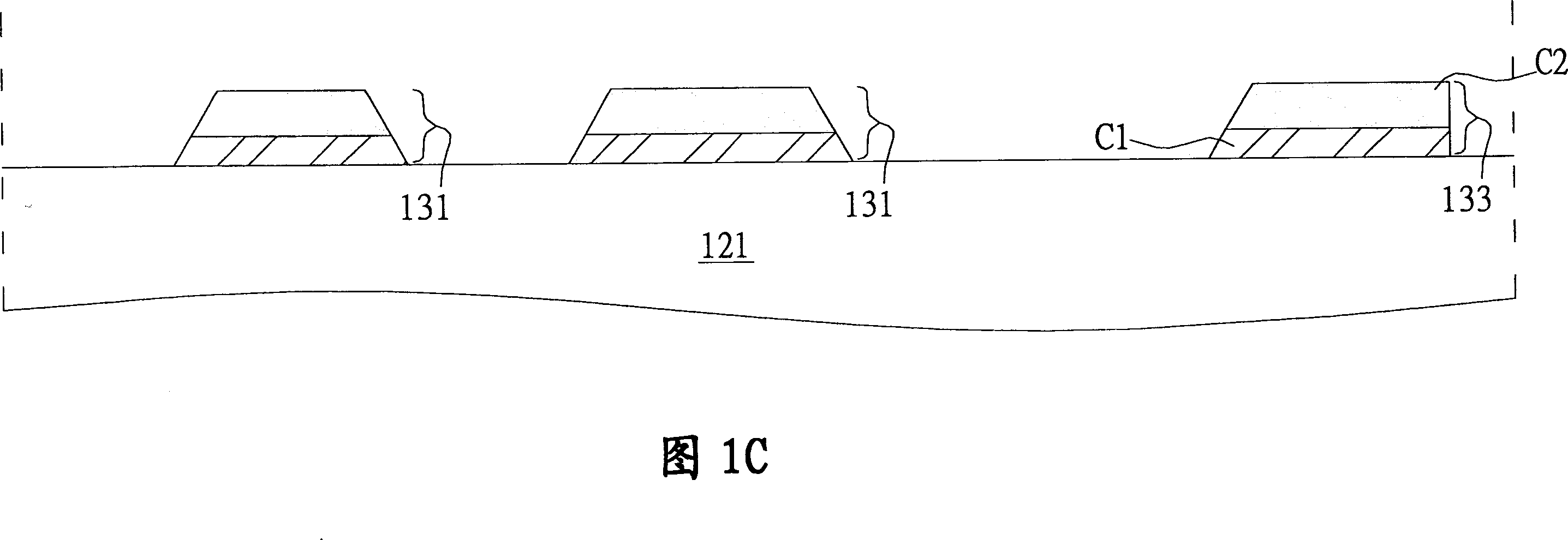

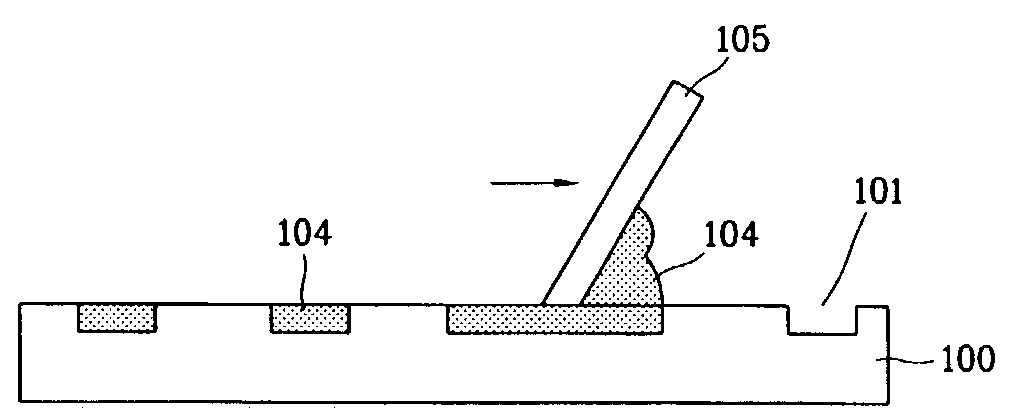

Patterning using wax printing and lift off

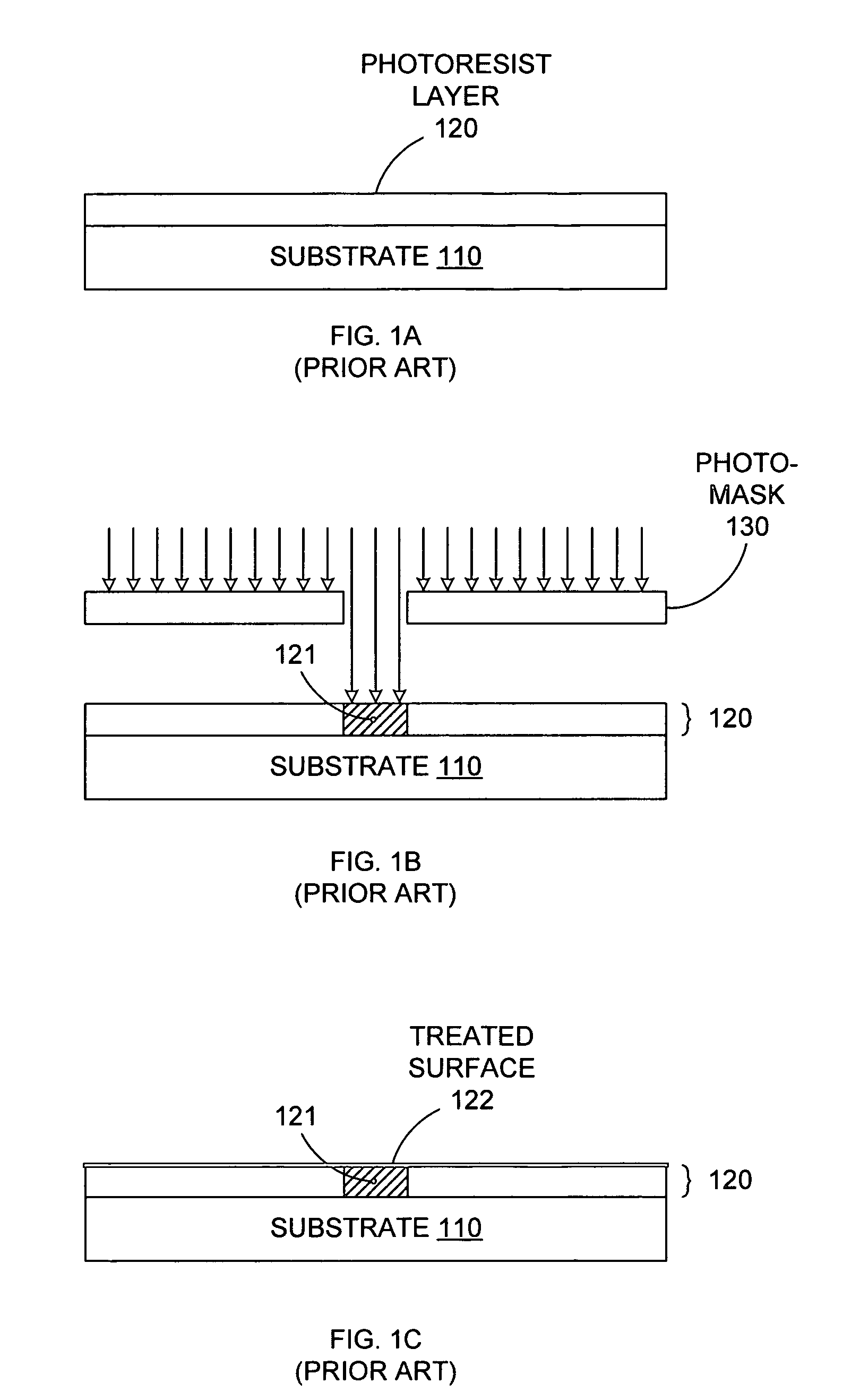

InactiveUS20050136358A1Low production costEasy alignmentTransistorPhotomechanical apparatusWaxImage resolution

A method for performing a liftoff operation involves printing a liftoff pattern using low-resolution patterning techniques to form fine feature patterns. The resulting feature size is defined by the spacing between printed patterns rather than the printed pattern size. By controlling the cross-sectional profile of the printed liftoff pattern, mask structures may be formed from the liftoff operation having beneficial etch-mask aperture profiles. For example, a multi-layer printed liftoff pattern can be used to create converging aperture profiles in a patterned layer. The patterned layer can then be used as an etch mask, where the converging aperture profiles result in desirable diverging etched features.

Owner:PALO ALTO RES CENT INC

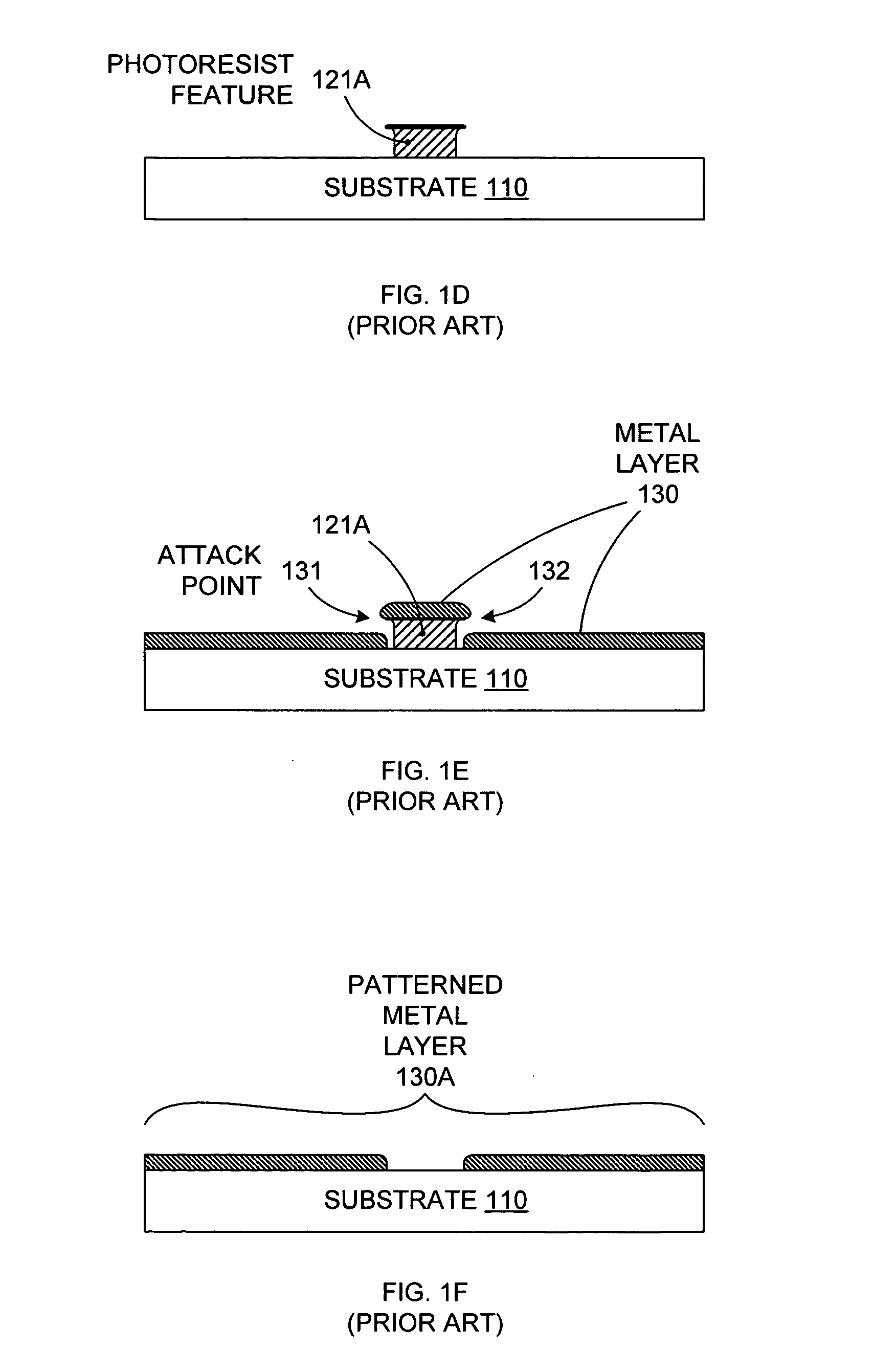

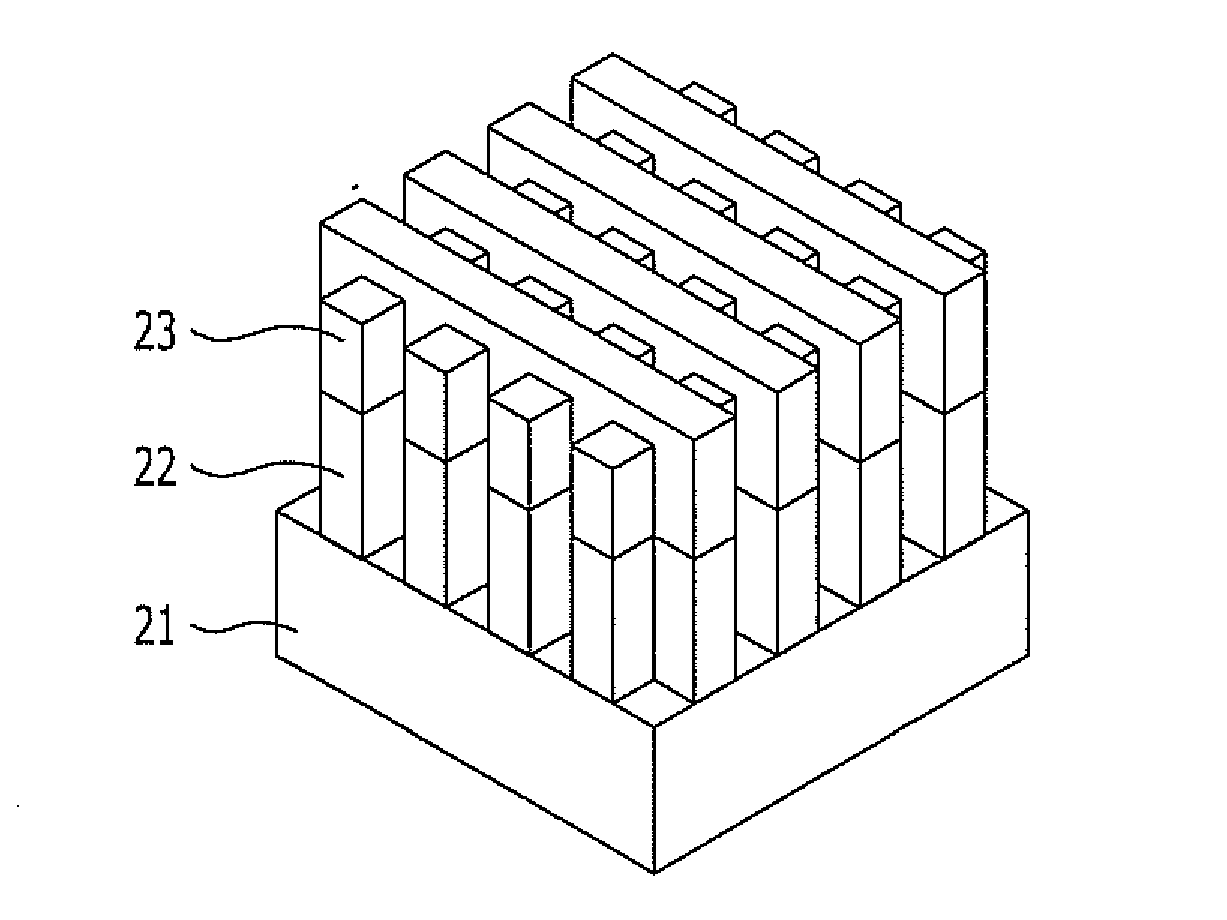

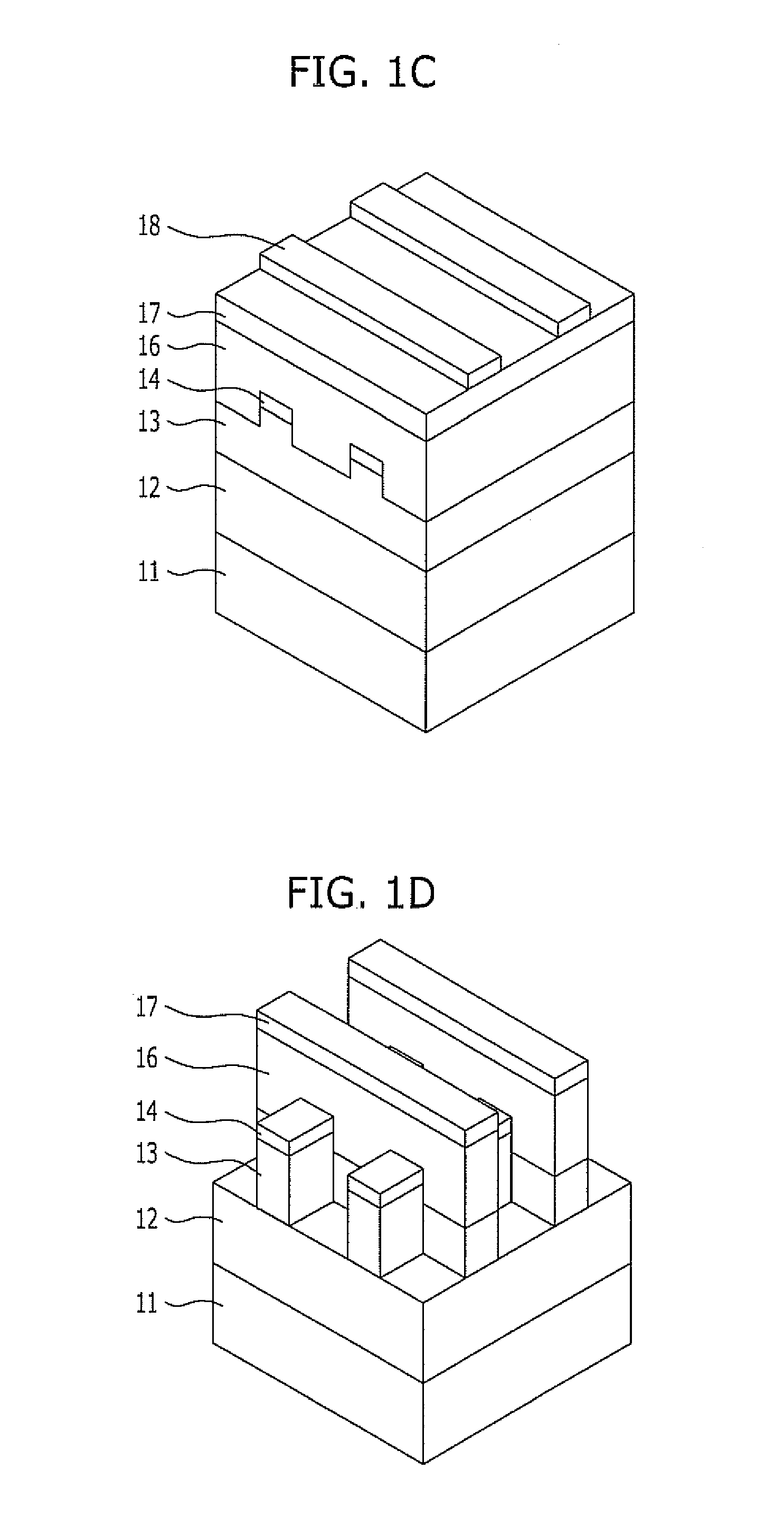

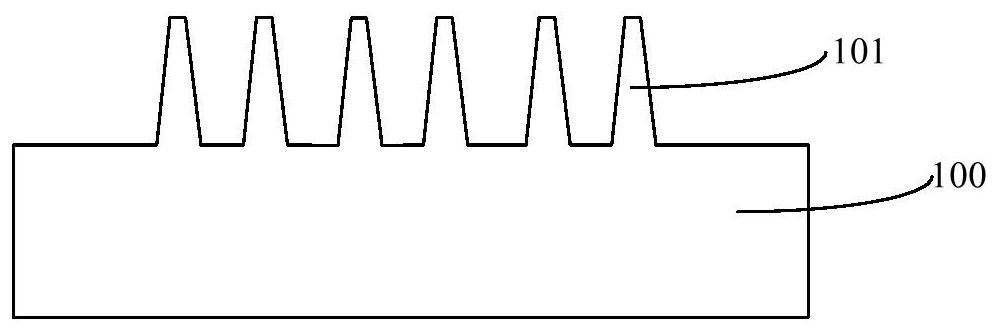

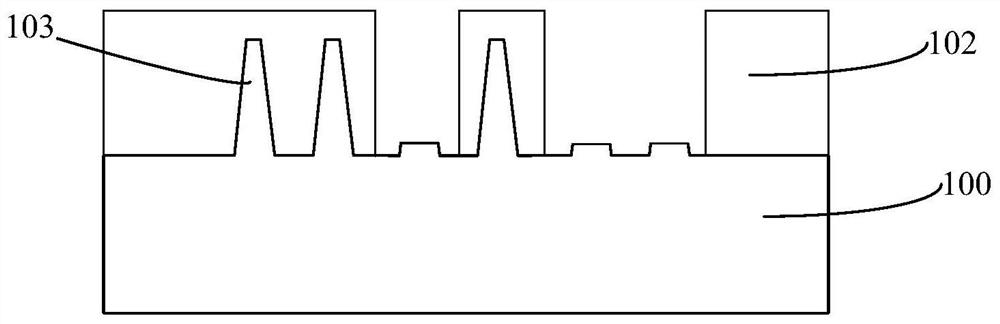

Method of fabricating a fin field effect transistor (FinFET) device

InactiveUS7829951B2Simplify the patterning processLarge feature sizeTransistorSolid-state devicesEngineeringField-effect transistor

Owner:QUALCOMM INC

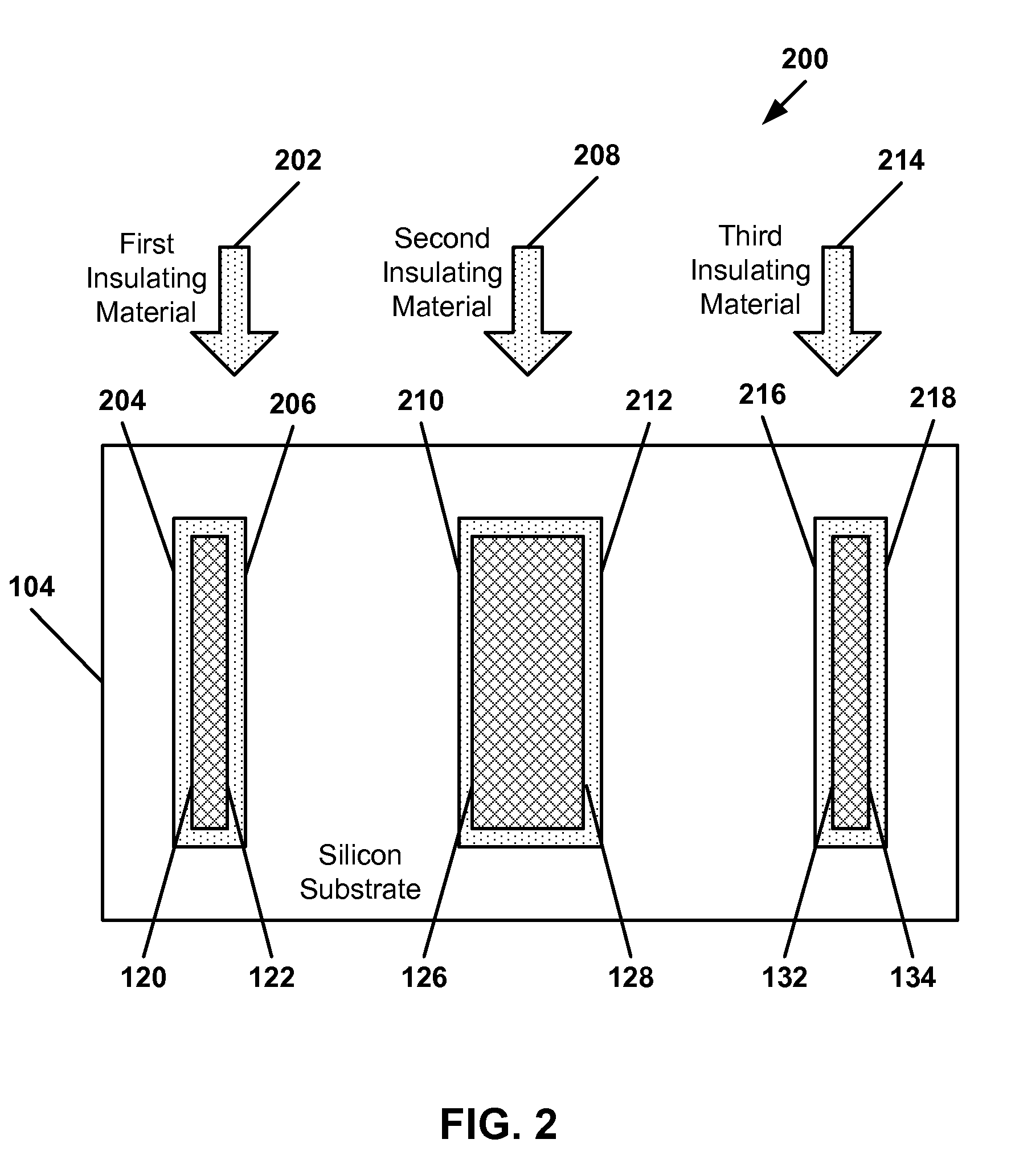

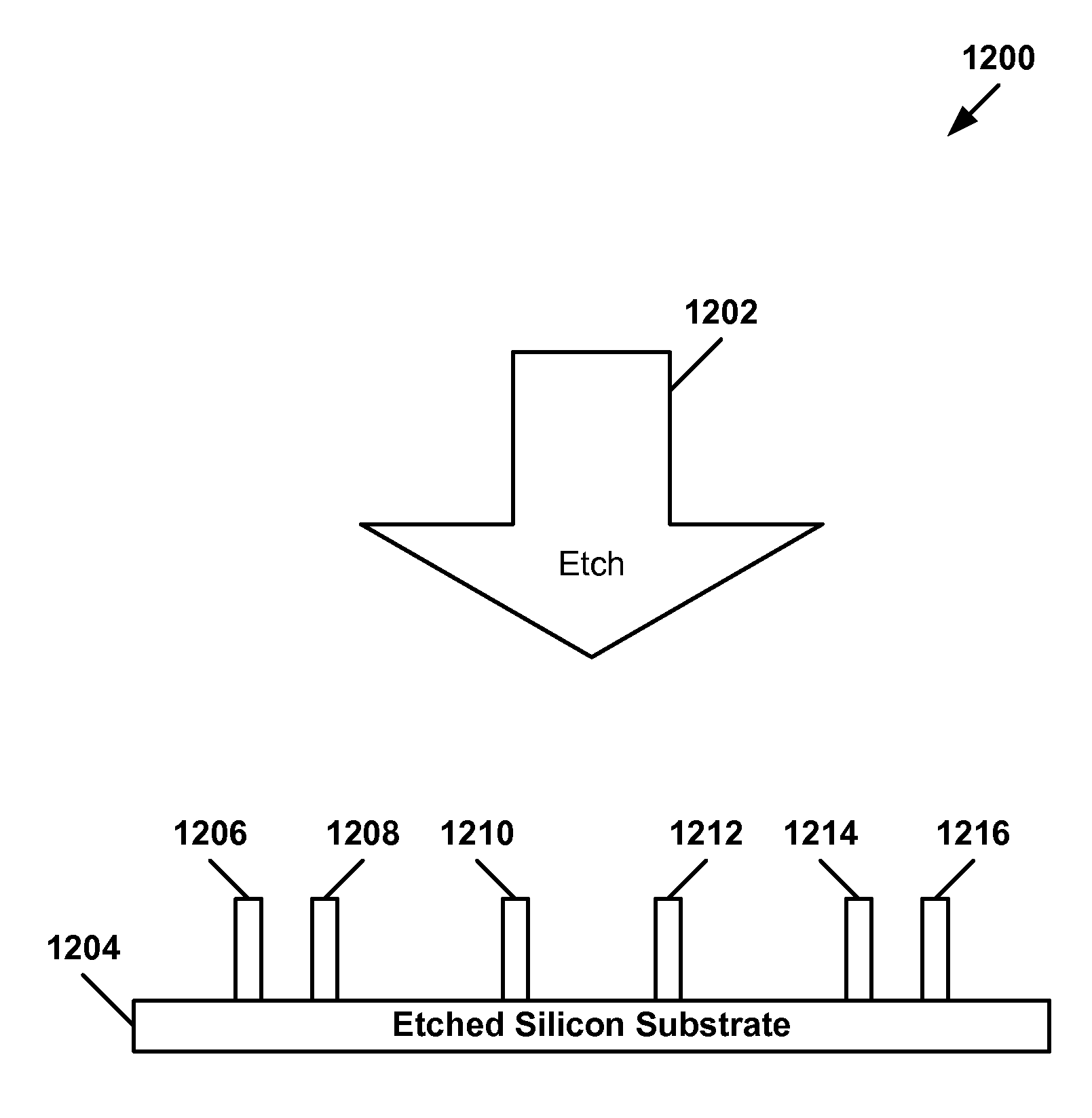

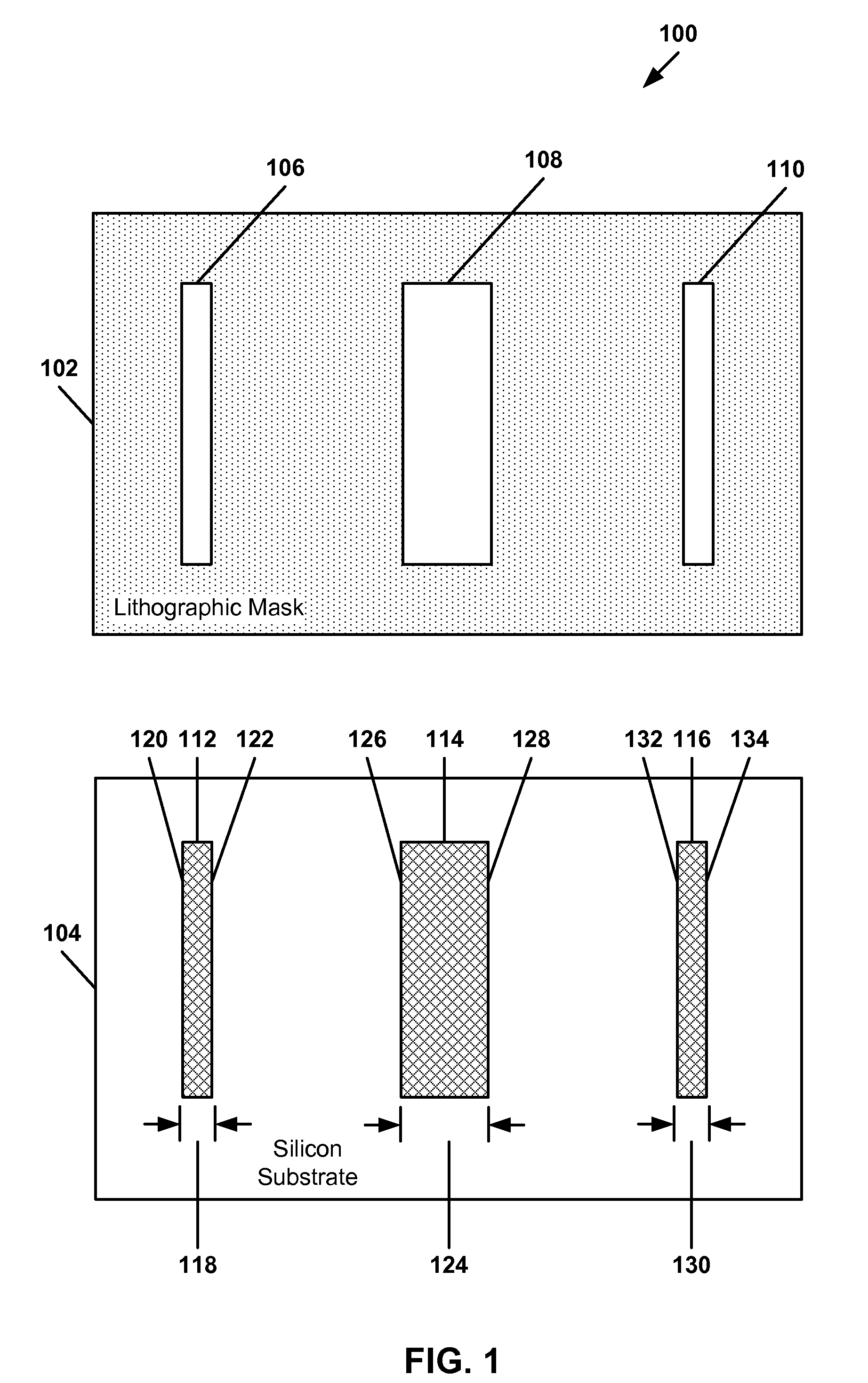

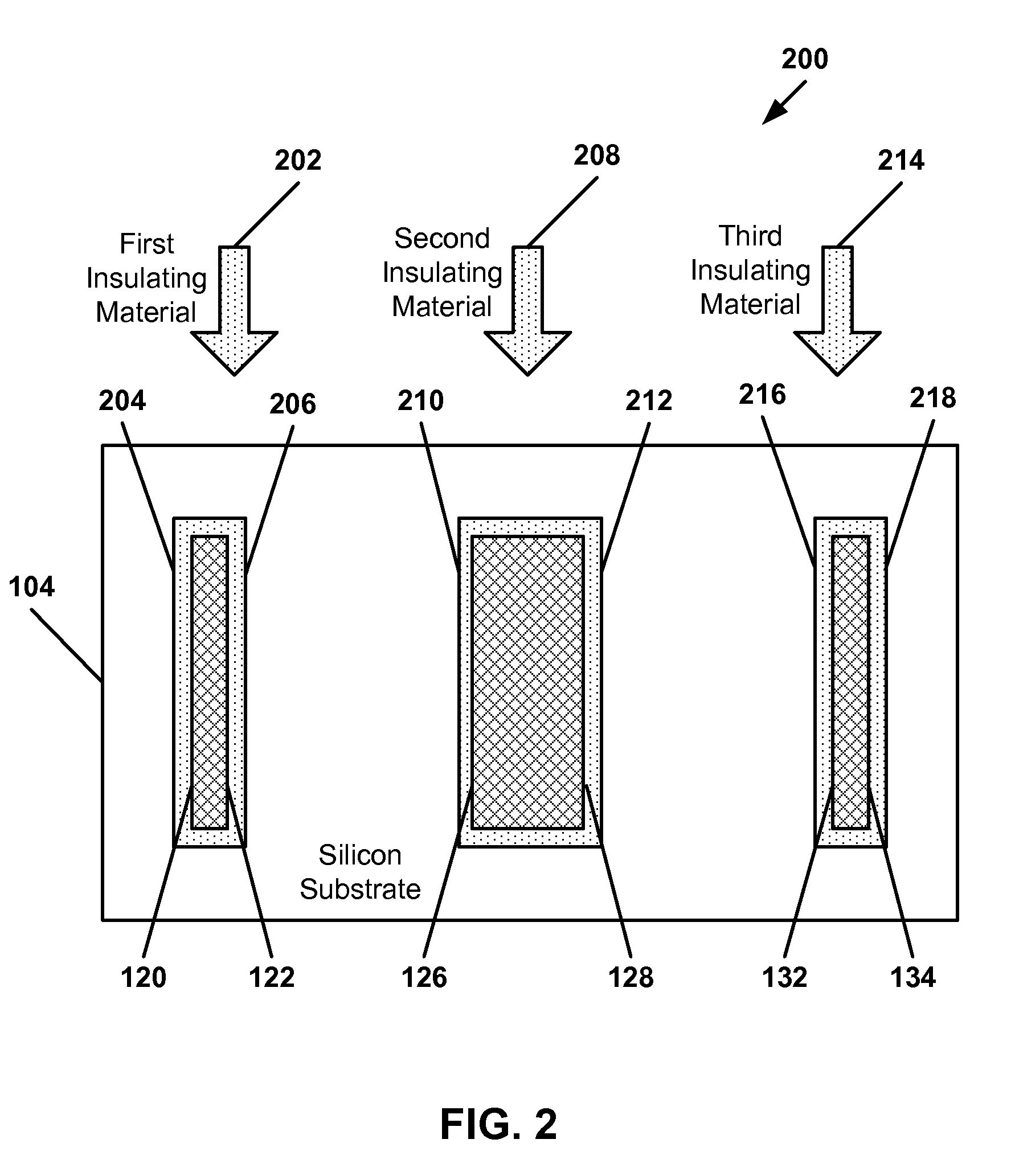

Method of Fabricating A Fin Field Effect Transistor (FinFET) Device

InactiveUS20100109086A1Simplified dummy structure patterning processLarge feature sizeTransistorSolid-state devicesEngineeringField-effect transistor

A method of fabricating a semiconductor using a fin field effect transistor (FINFET) is disclosed. In a particular embodiment, a method includes depositing, on a silicon substrate, a first dummy structure having a first sidewall and a second sidewall separated by a first width. The method also includes depositing, on the silicon substrate, a second dummy structure concurrently with depositing the first dummy structure. The second dummy structure has a third sidewall and a fourth sidewall that are separated by a second width. The second width is substantially greater than the first width. The first dummy structure is used to form a first pair of fins separated by approximately the first width. The second dummy structure is used to form a second pair of fins separated by approximately the second width.

Owner:QUALCOMM INC

Patterning using wax printing and lift off

InactiveUS7309563B2Low production costSimplify the patterning processTransistorPhotomechanical apparatusWaxImage resolution

A method for performing a liftoff operation involves printing a liftoff pattern using low-resolution patterning techniques to form fine feature patterns. The resulting feature size is defined by the spacing between printed patterns rather than the printed pattern size. By controlling the cross-sectional profile of the printed liftoff pattern, mask structures may be formed from the liftoff operation having beneficial etch-mask aperture profiles. For example, a multi-layer printed liftoff pattern can be used to create converging aperture profiles in a patterned layer. The patterned layer can then be used as an etch mask, where the converging aperture profiles result in desirable diverging etched features.

Owner:PALO ALTO RES CENT INC

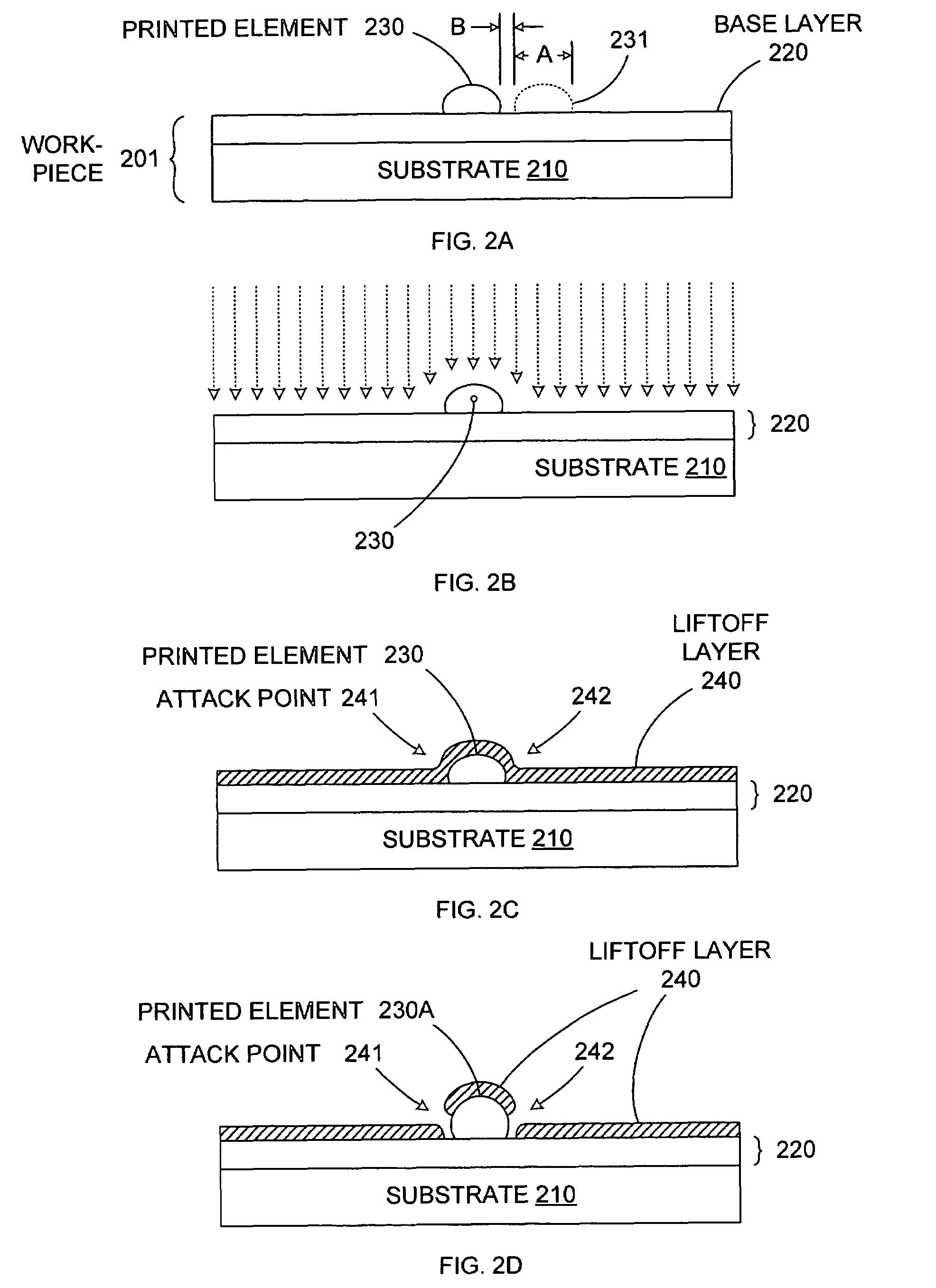

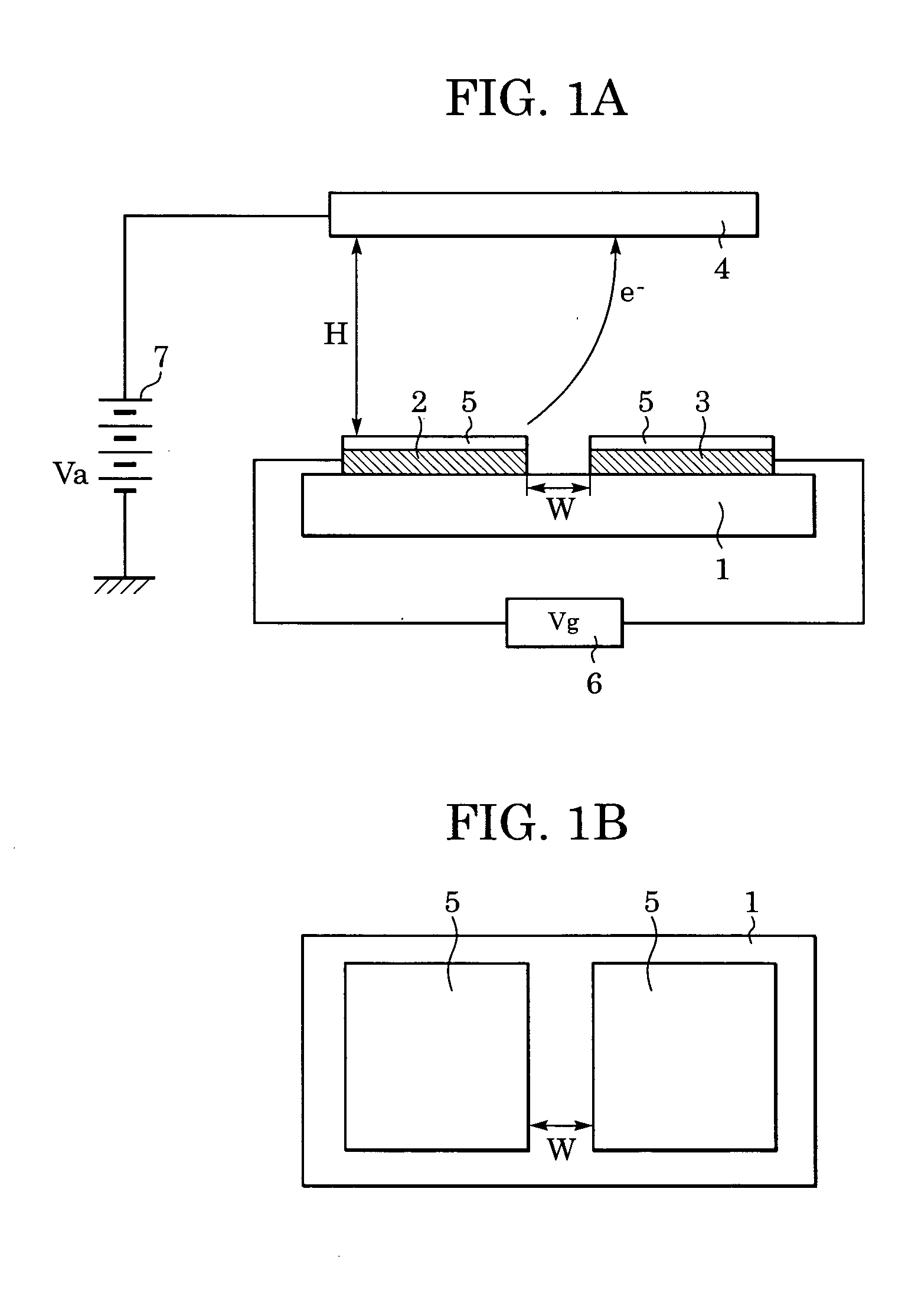

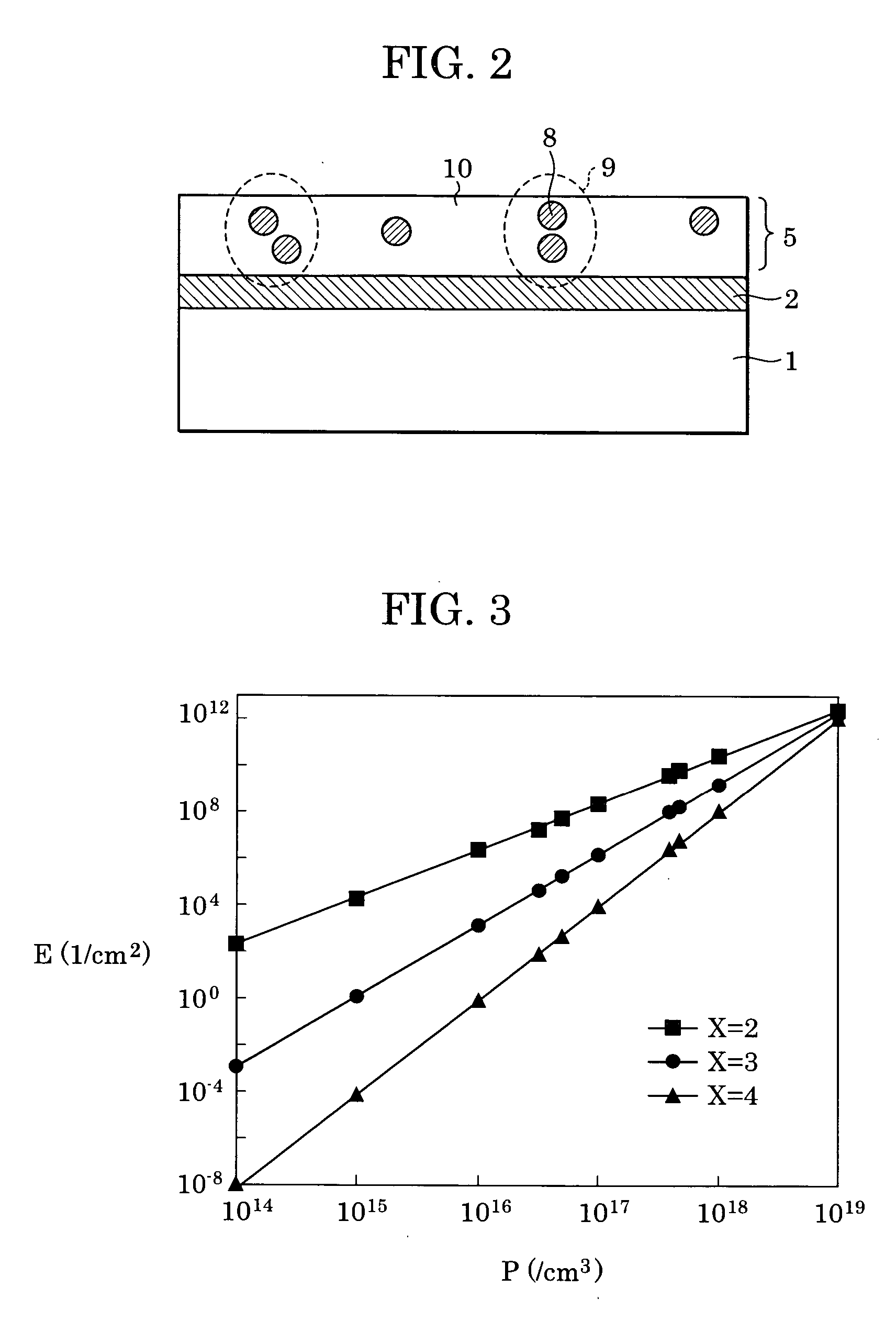

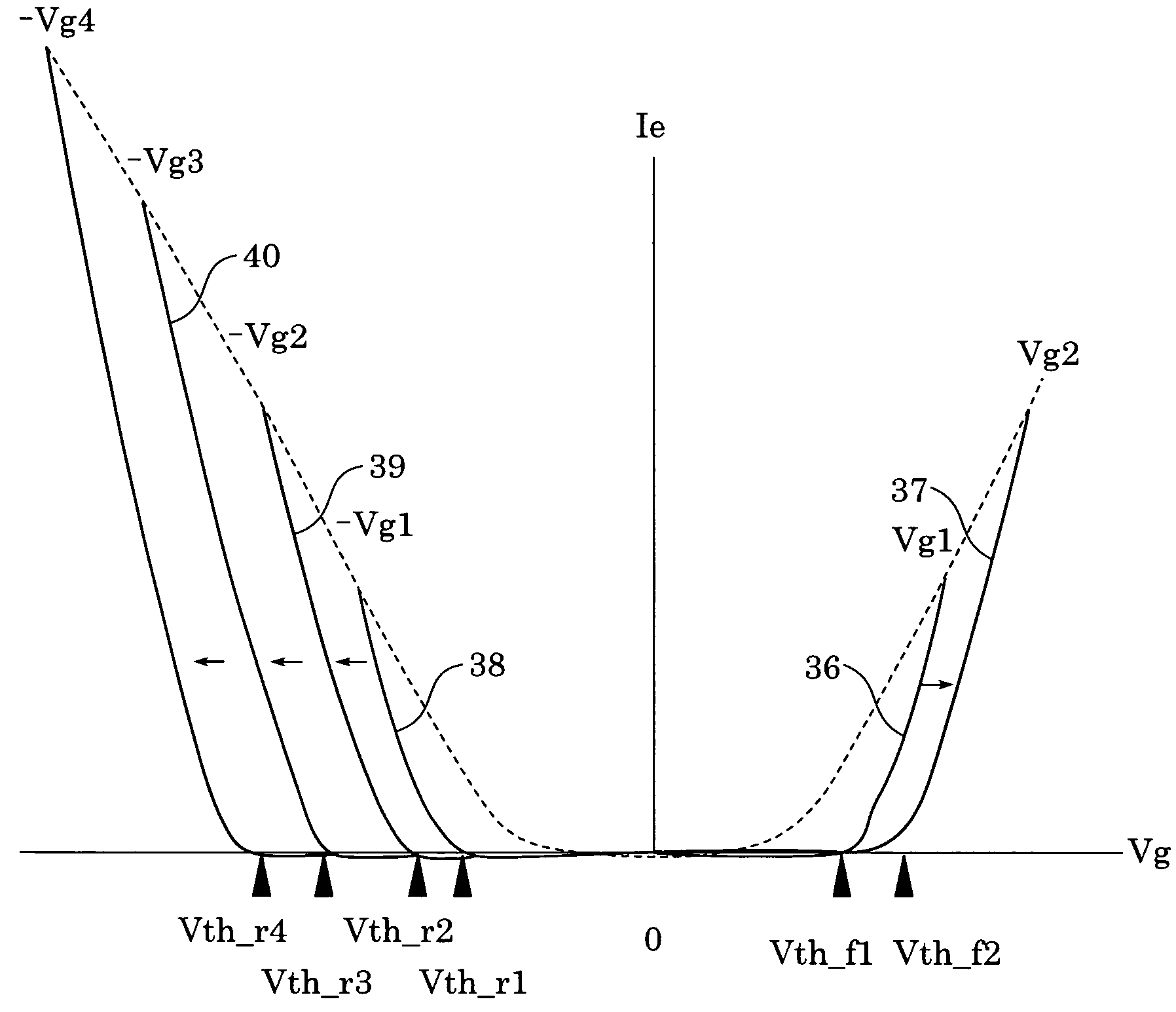

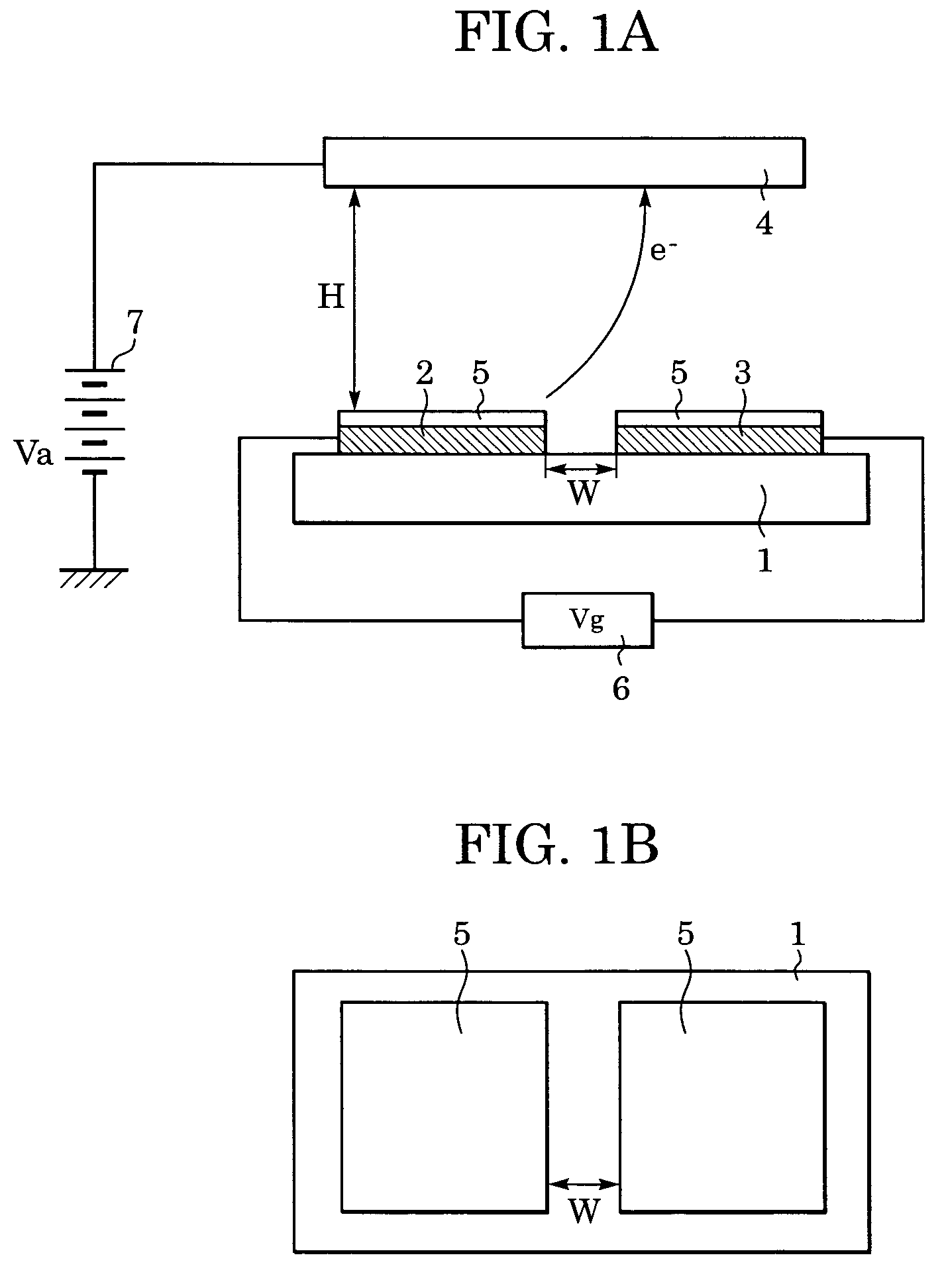

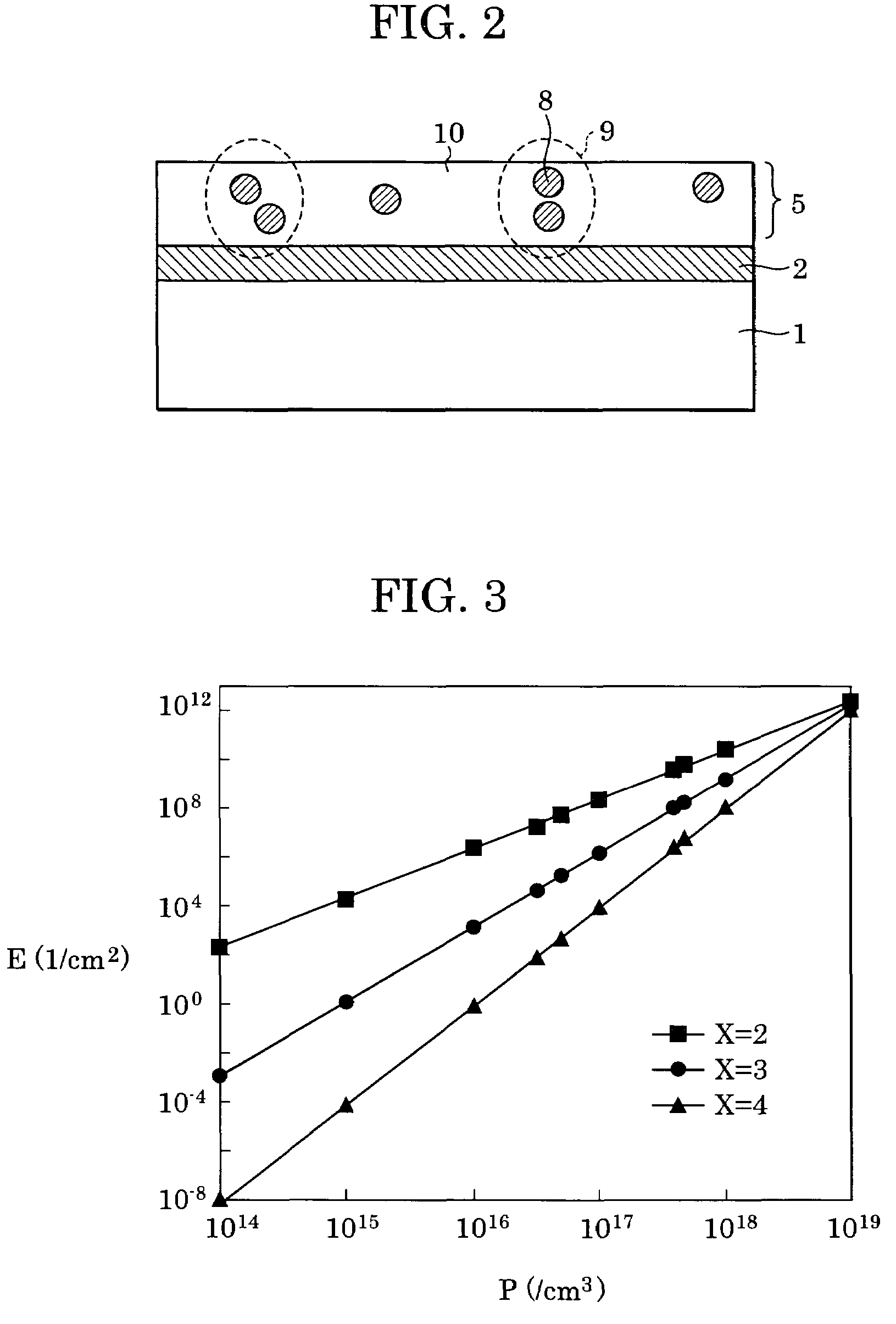

Method of producing an electron emission device, method of producing an electron source, method of producing an image display device, and method of driving an electron emission device

InactiveUS20050202745A1Simple structureEasy to controlSparking plugsDischarge tube luminescnet screensElectron sourceElectric field

A method of producing an electron emission device having a low threshold electric field needed to emit electrons without unintentional electron emission includes a first step of preparing a first conductive film, second conductive film, and a material which constitutes an electron emission part connected to the first conductive film, and a second step of setting a threshold electric field strength, which is needed to start electron emission in a situation where a higher electric potential is applied to the first conductive film than that applied to the second conductive film, to a value greater than a threshold electric field strength, which is needed to start electron emission in a situation where a higher electric potential is applied to the second conductive film than that applied to the first conductive film.

Owner:CANON KK

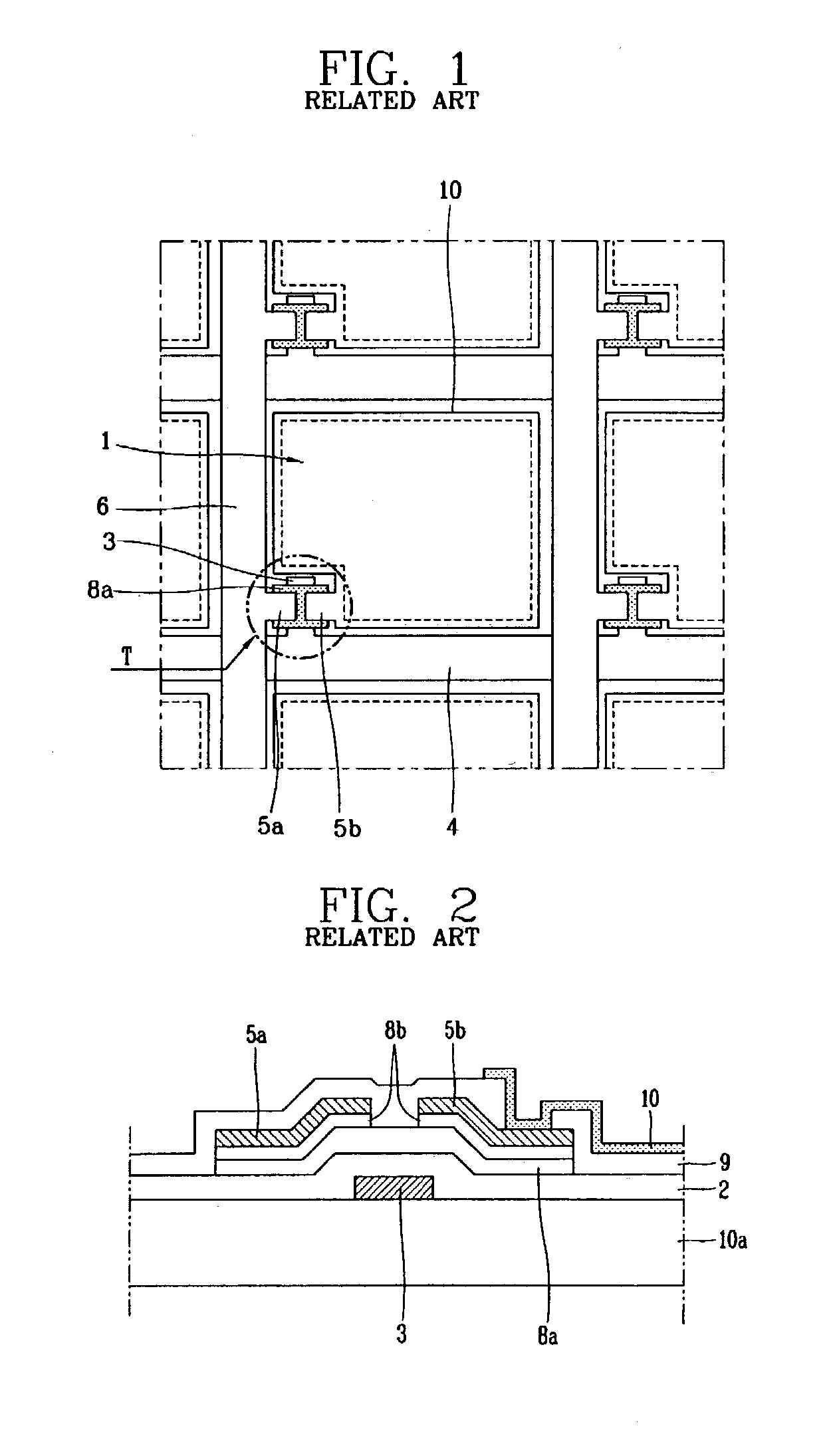

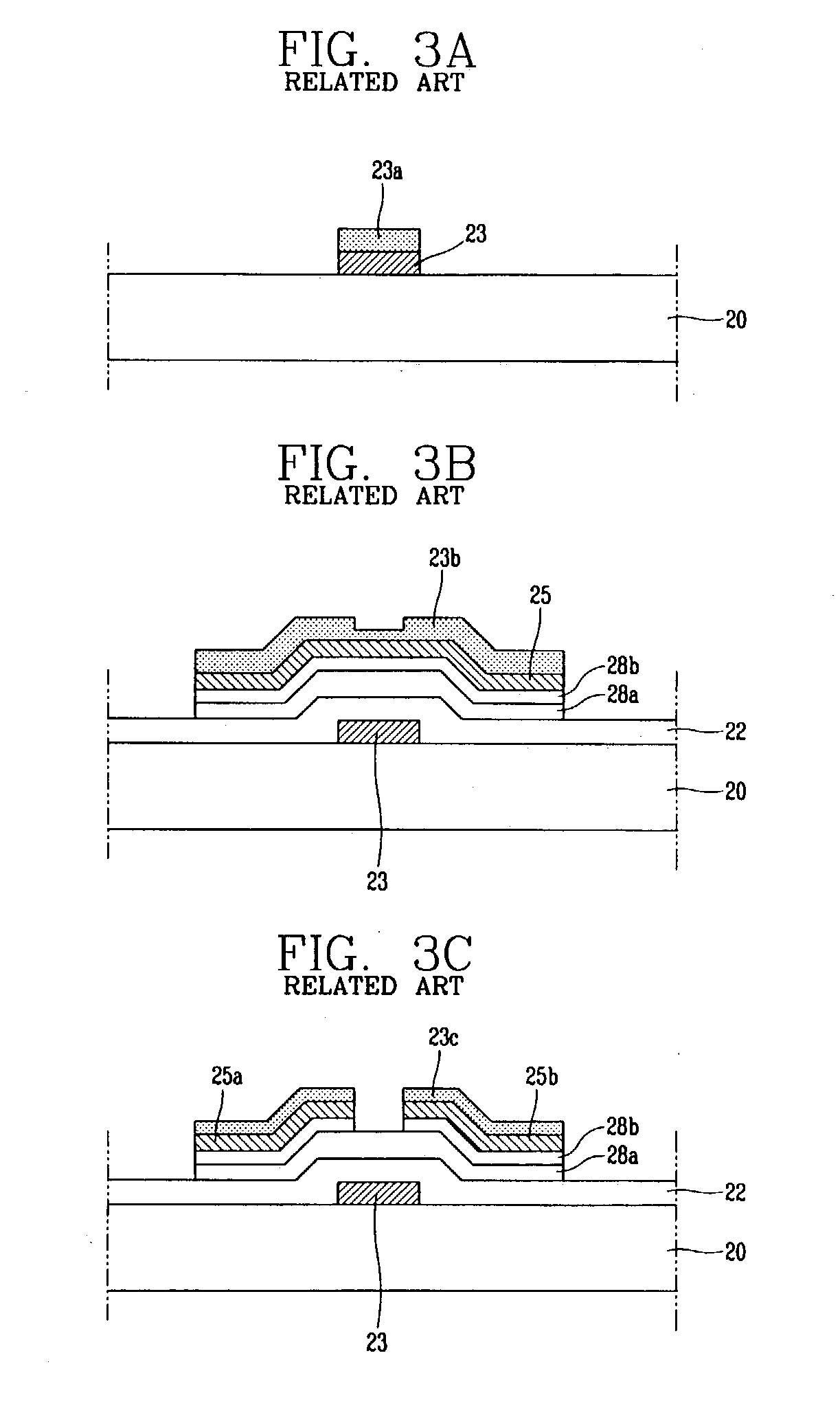

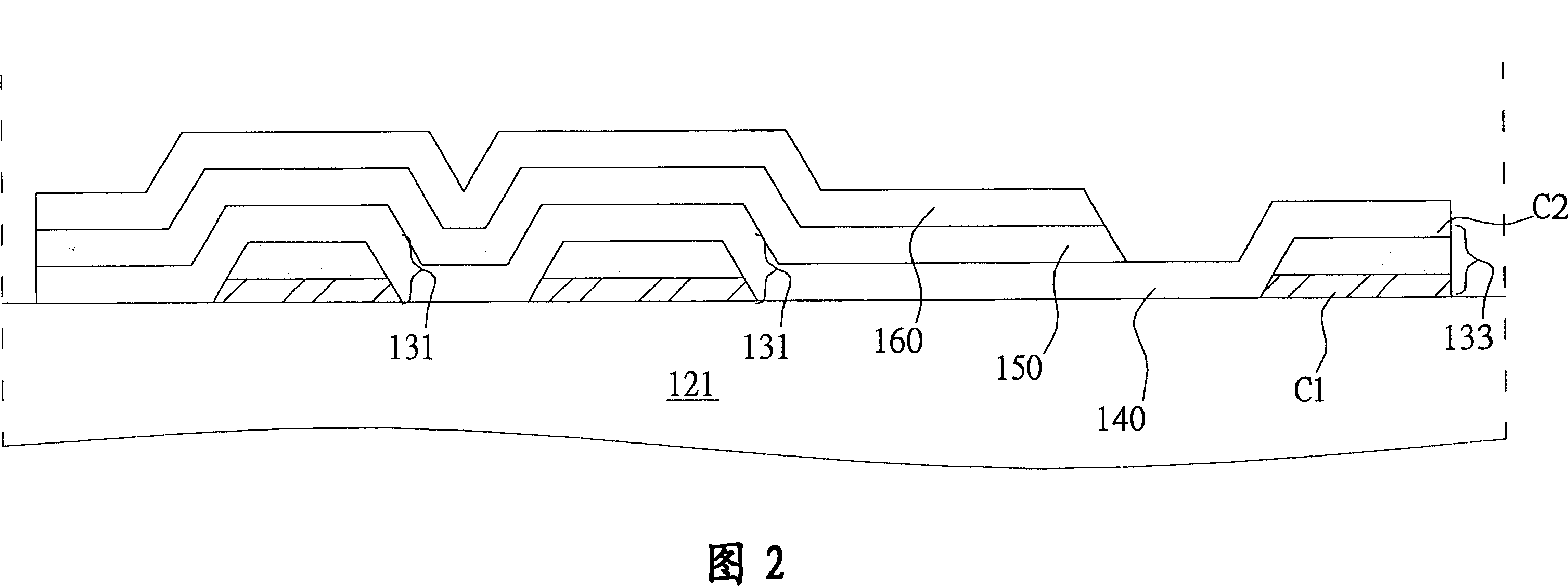

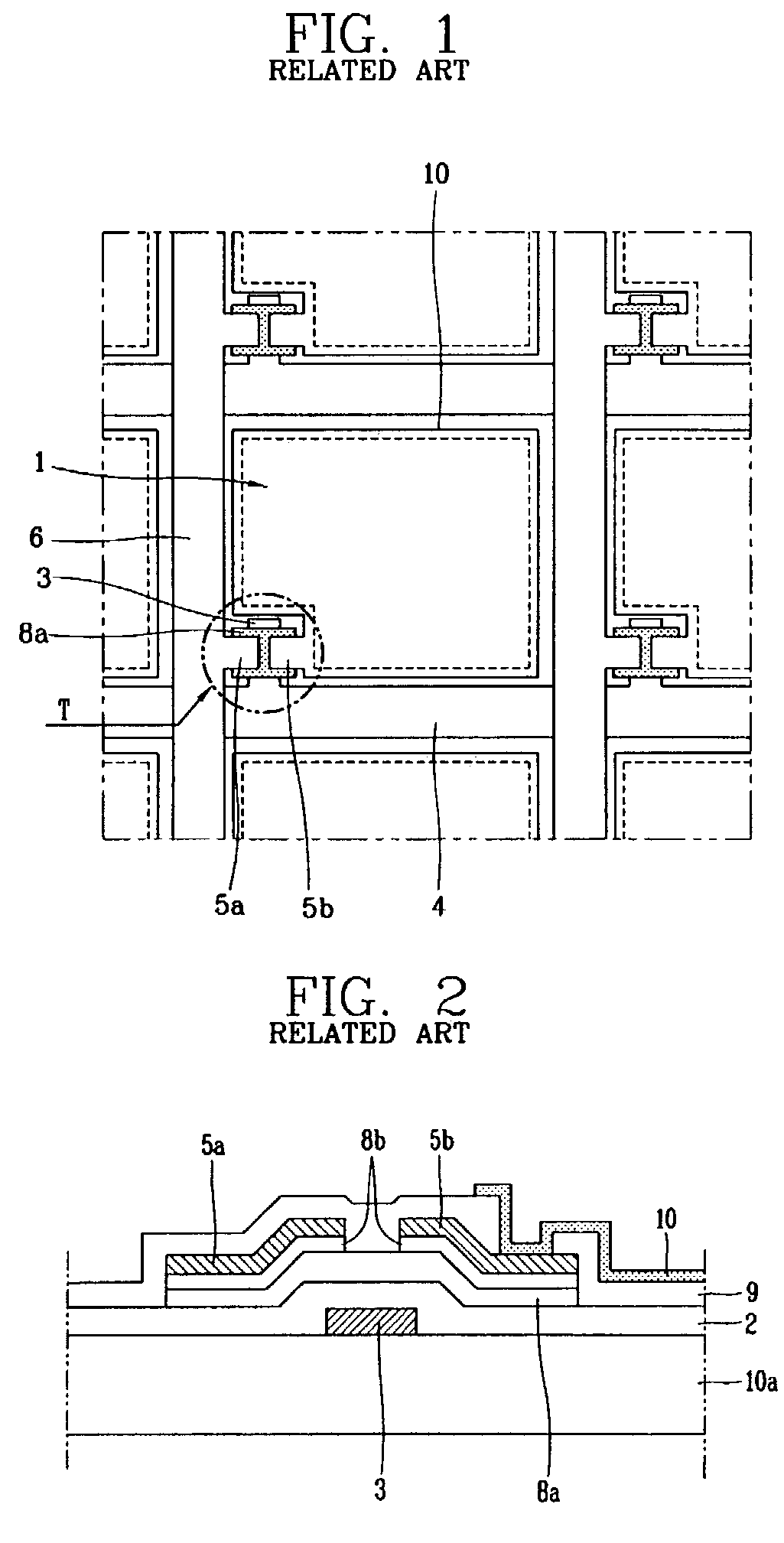

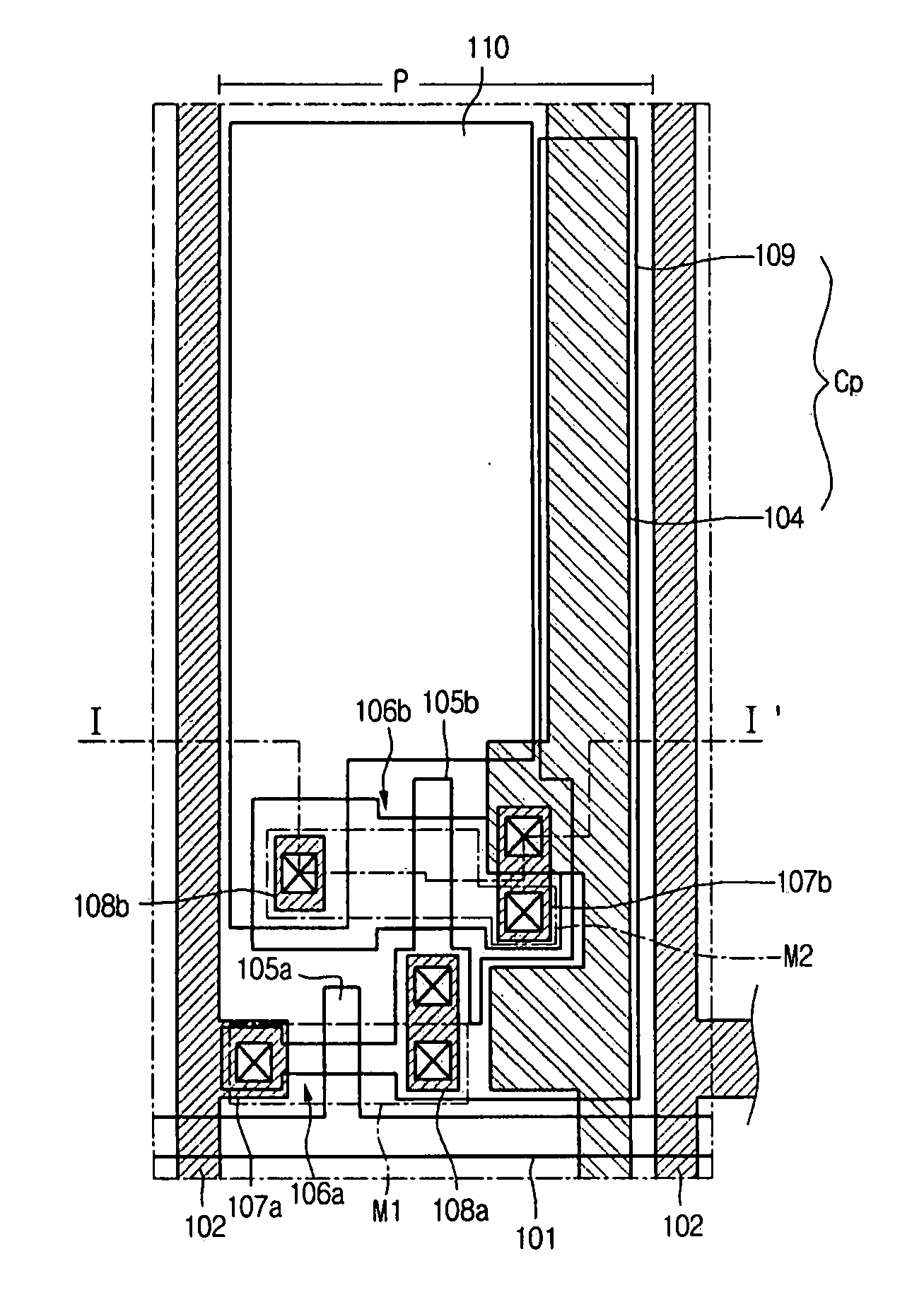

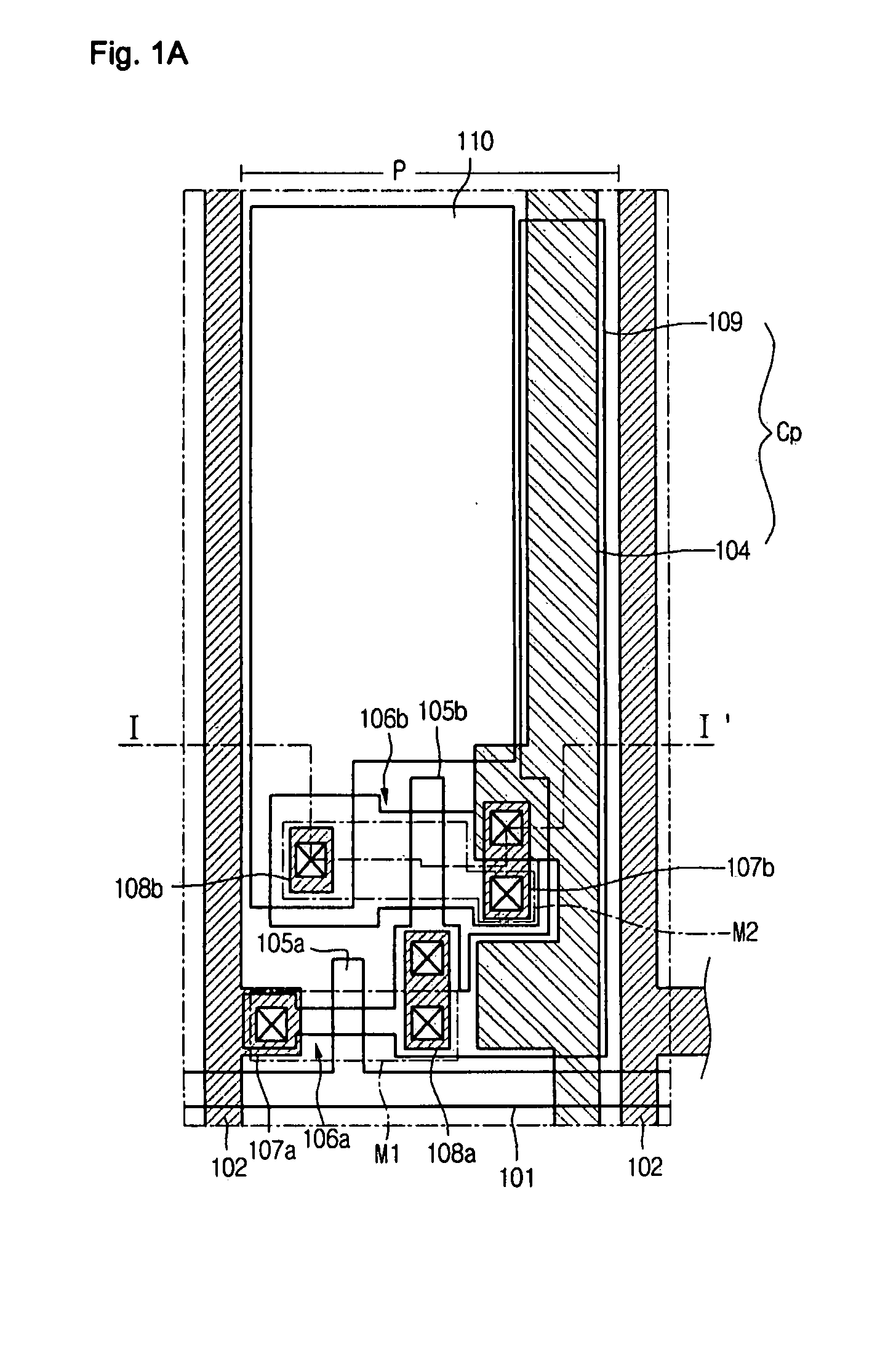

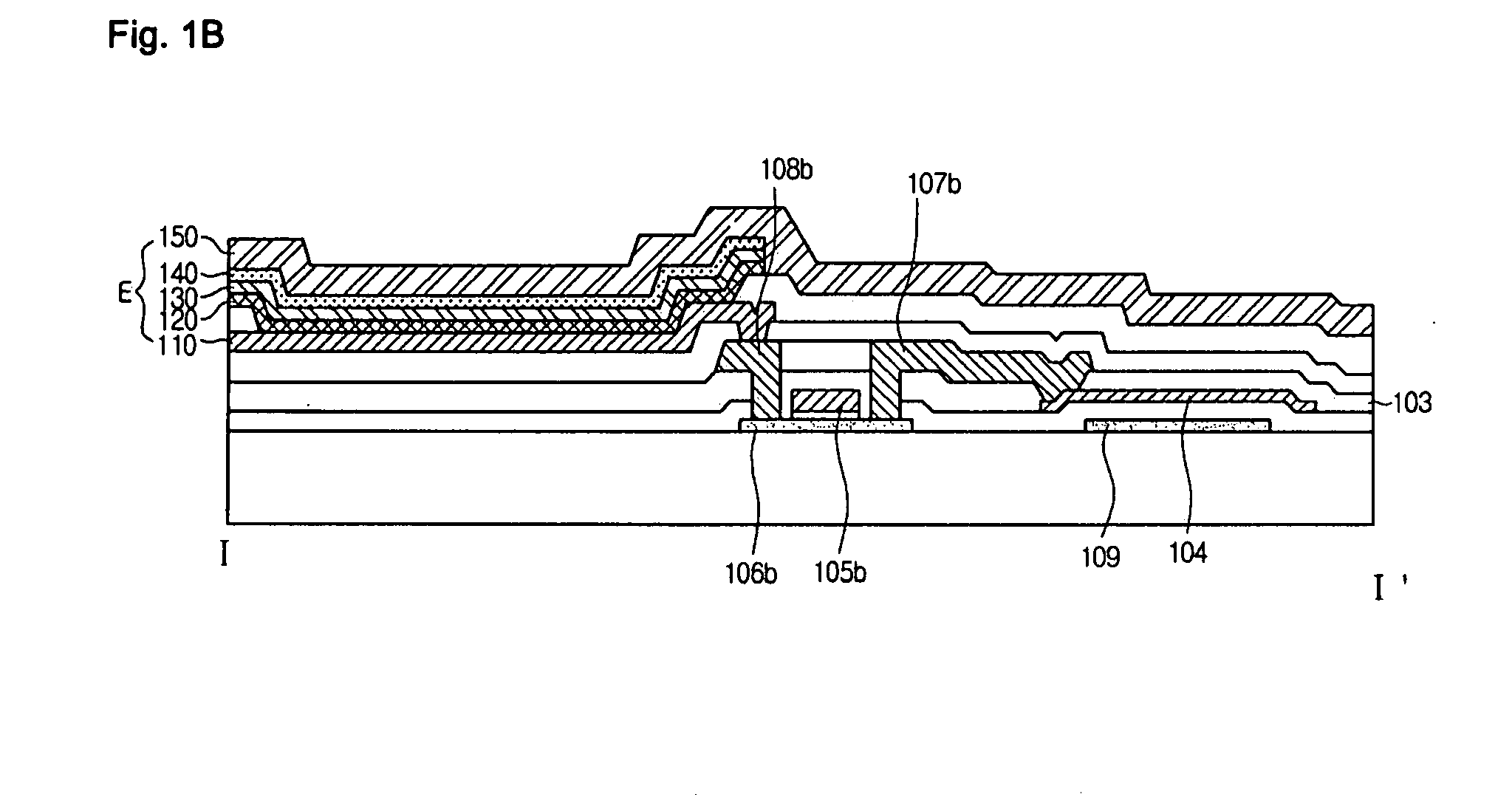

Fabrication method of liquid crystal display device

InactiveUS20030219920A1Simplify the patterning processTransistorAfter-treatment detailsResistLiquid-crystal display

Owner:LG DISPLAY CO LTD

Optoelectronic display and method of manufacturing the same

ActiveUS8115216B2Simplify the patterning processImprove performanceDischarge tube luminescnet screensStatic indicating devicesDisplay deviceComputer science

Owner:CAMBRIDGE DISPLAY TECH LTD

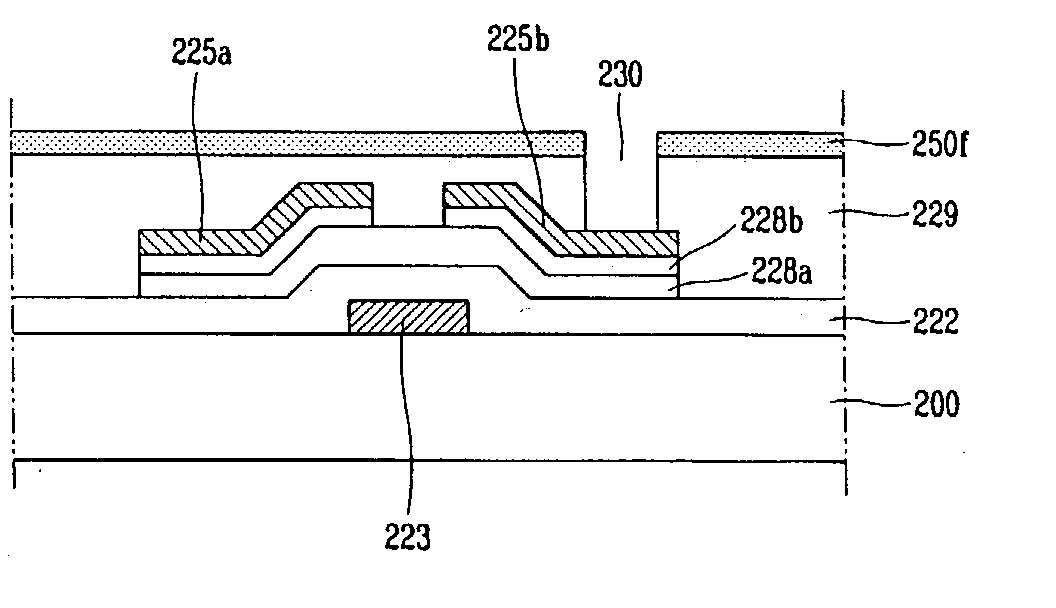

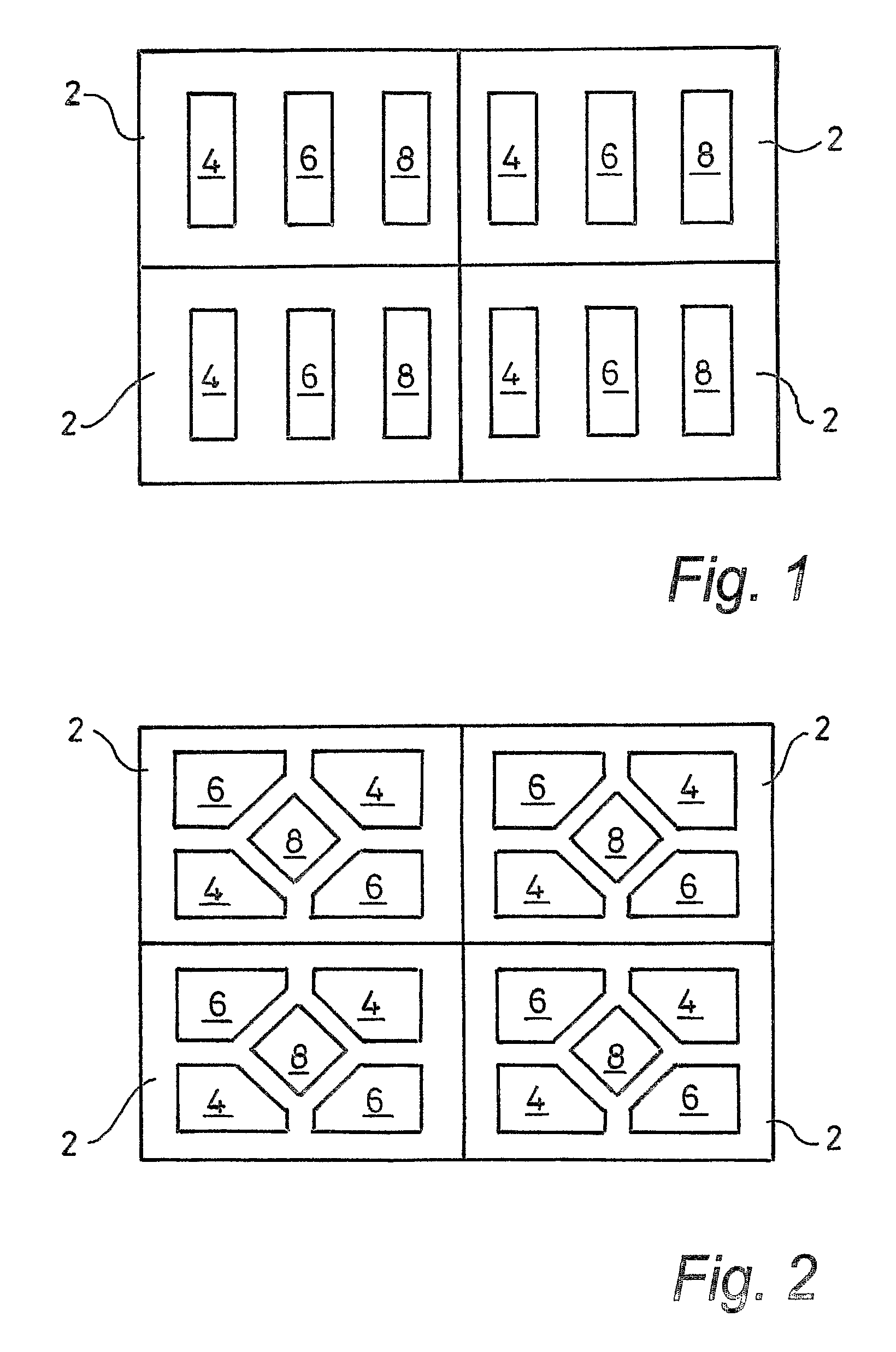

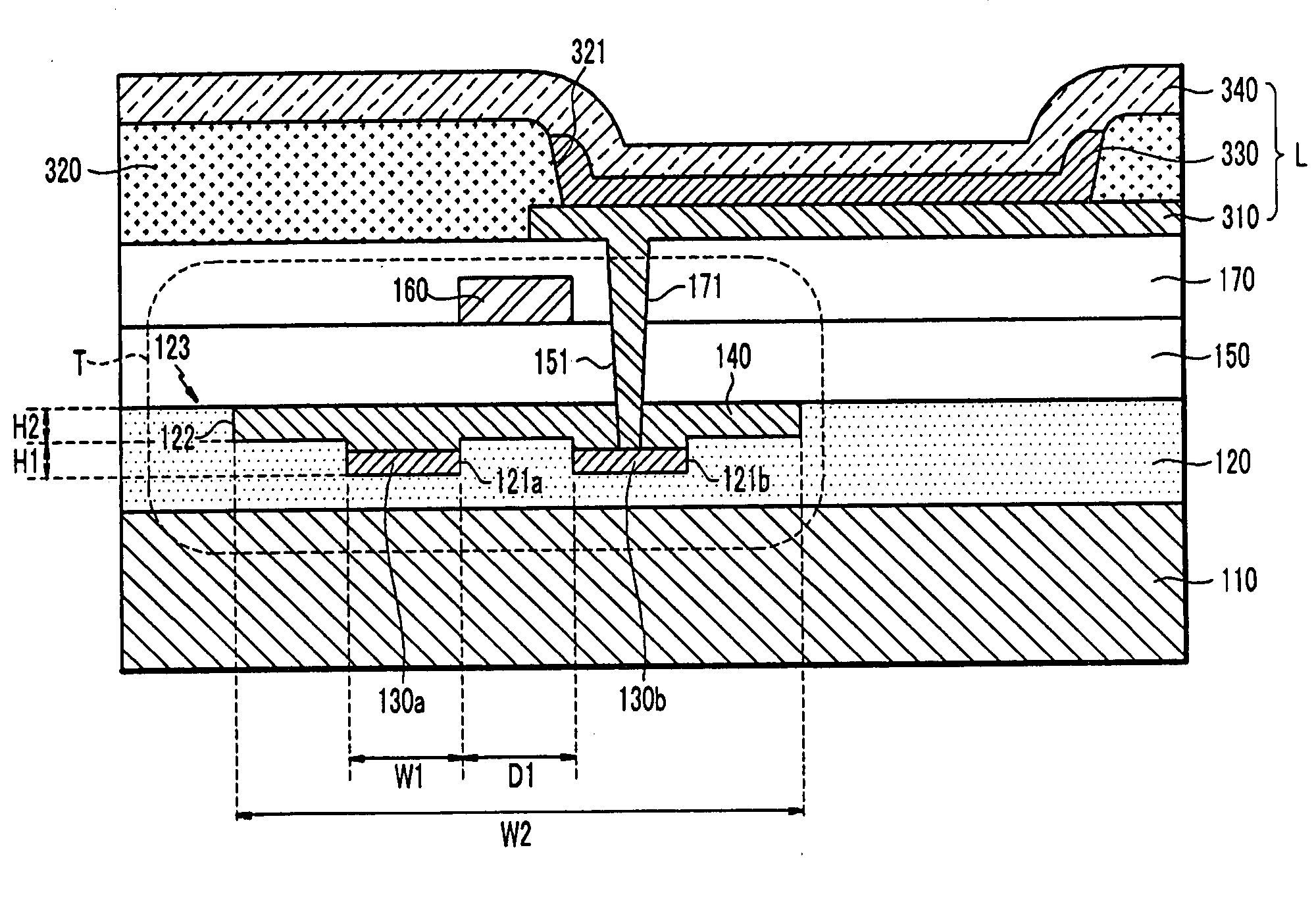

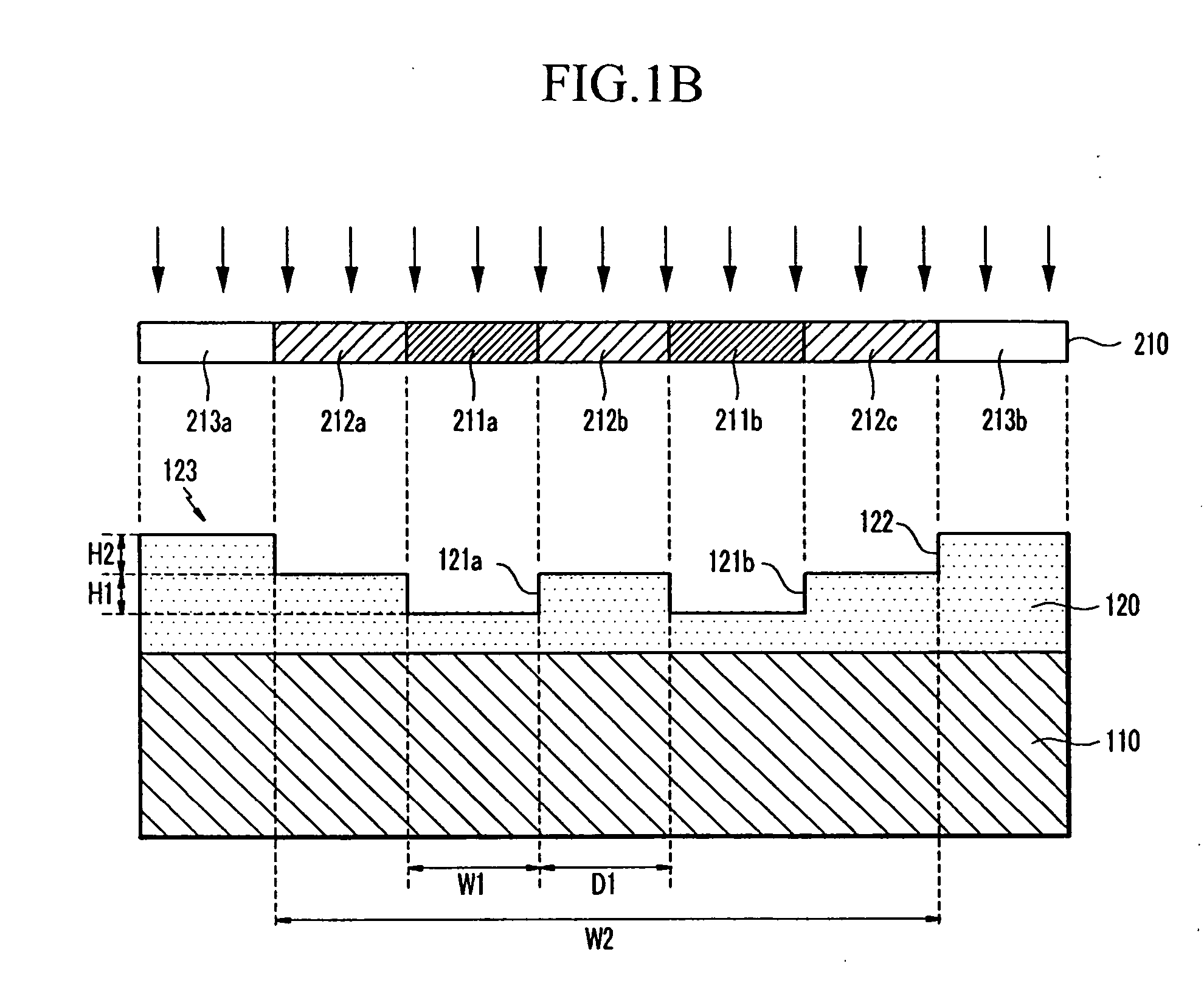

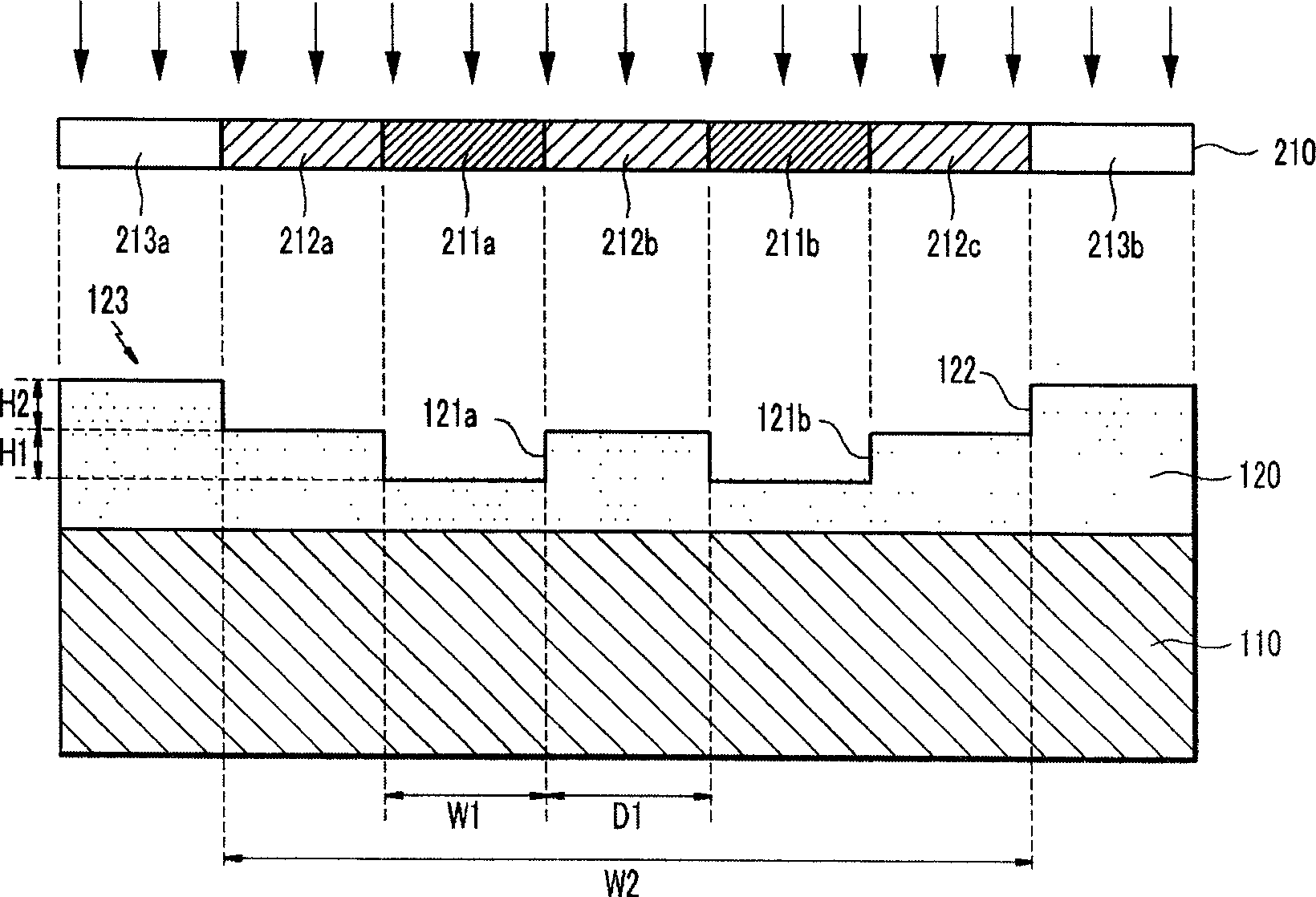

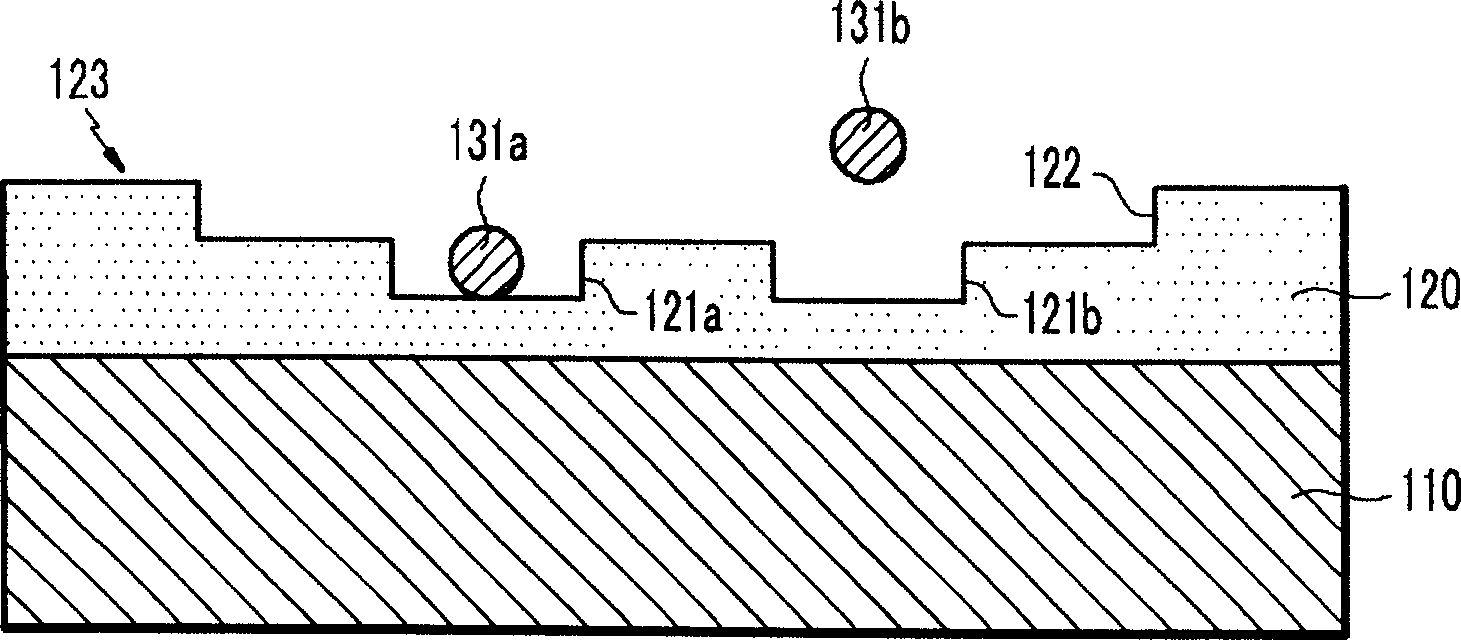

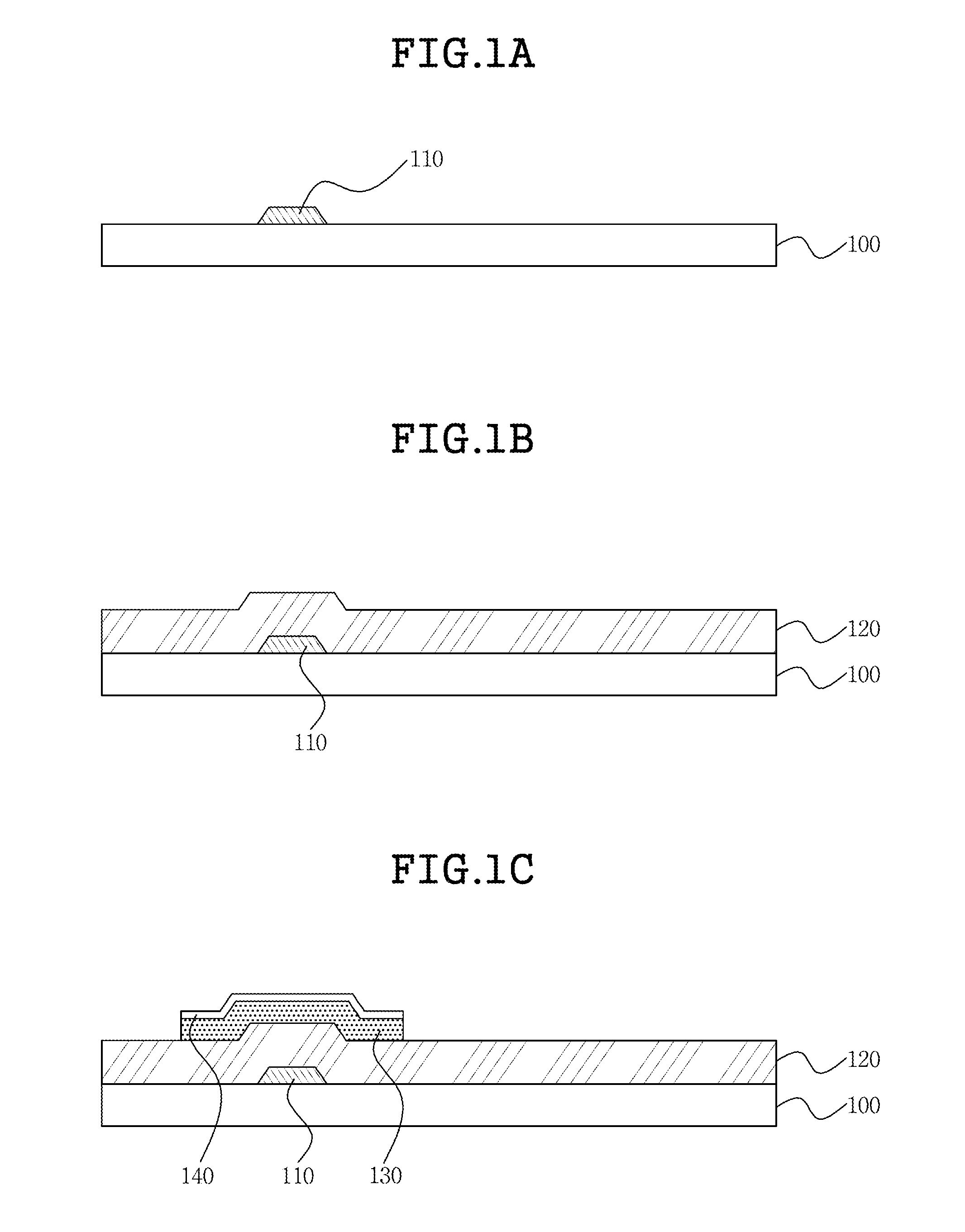

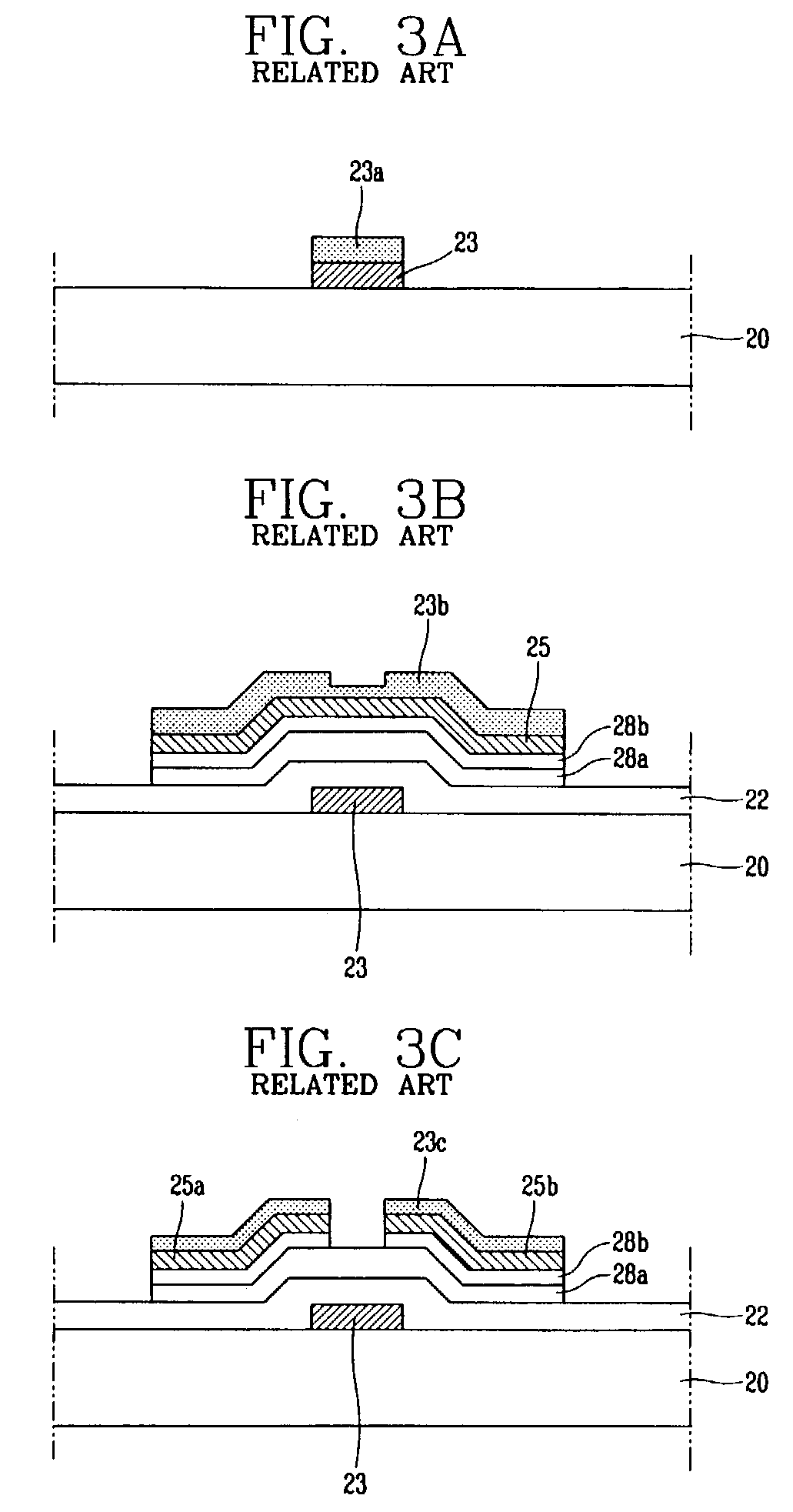

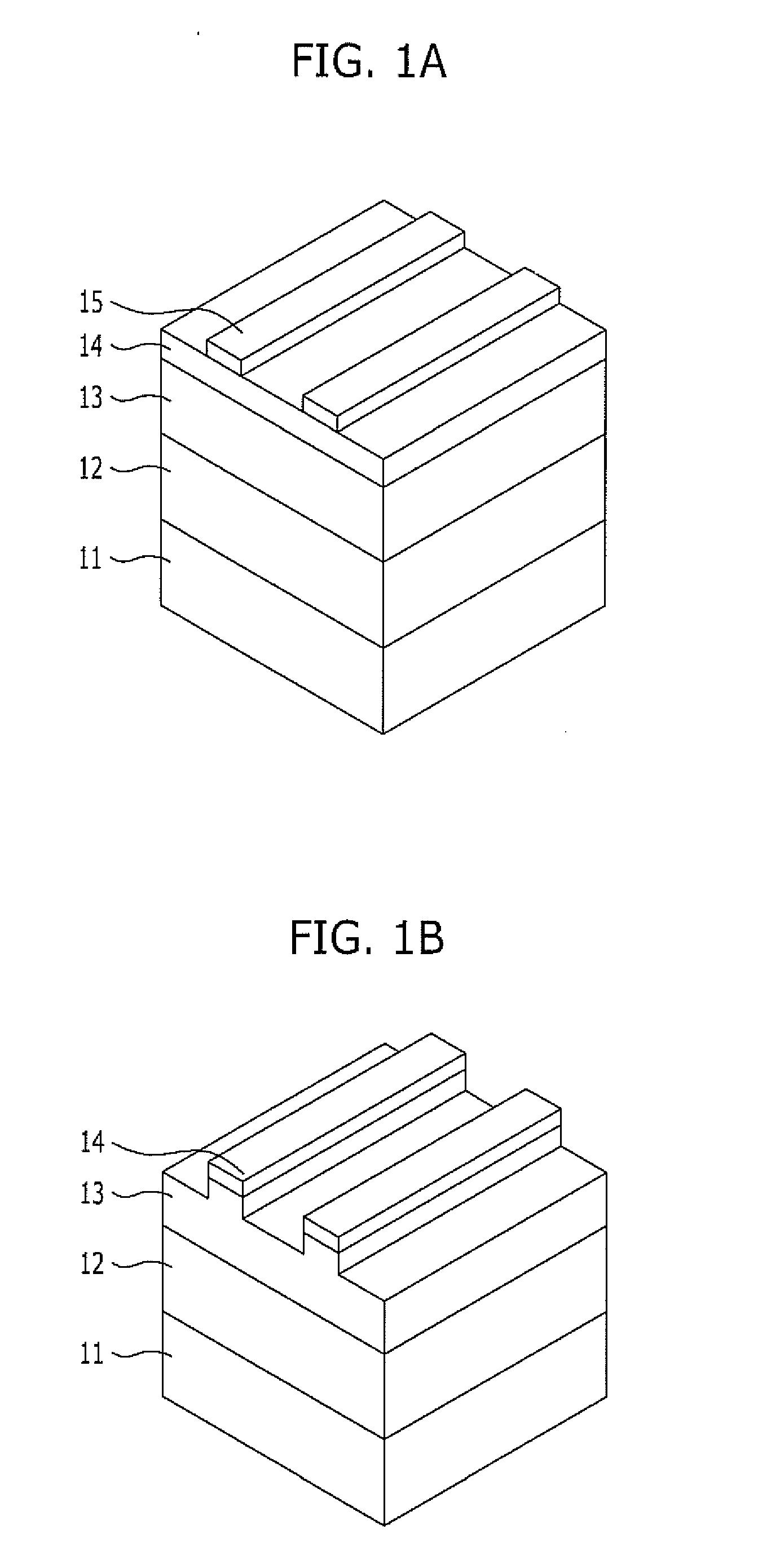

Method of manufacturing thin film transistor, thin film transistor manufactured by the method, and display device employing the same

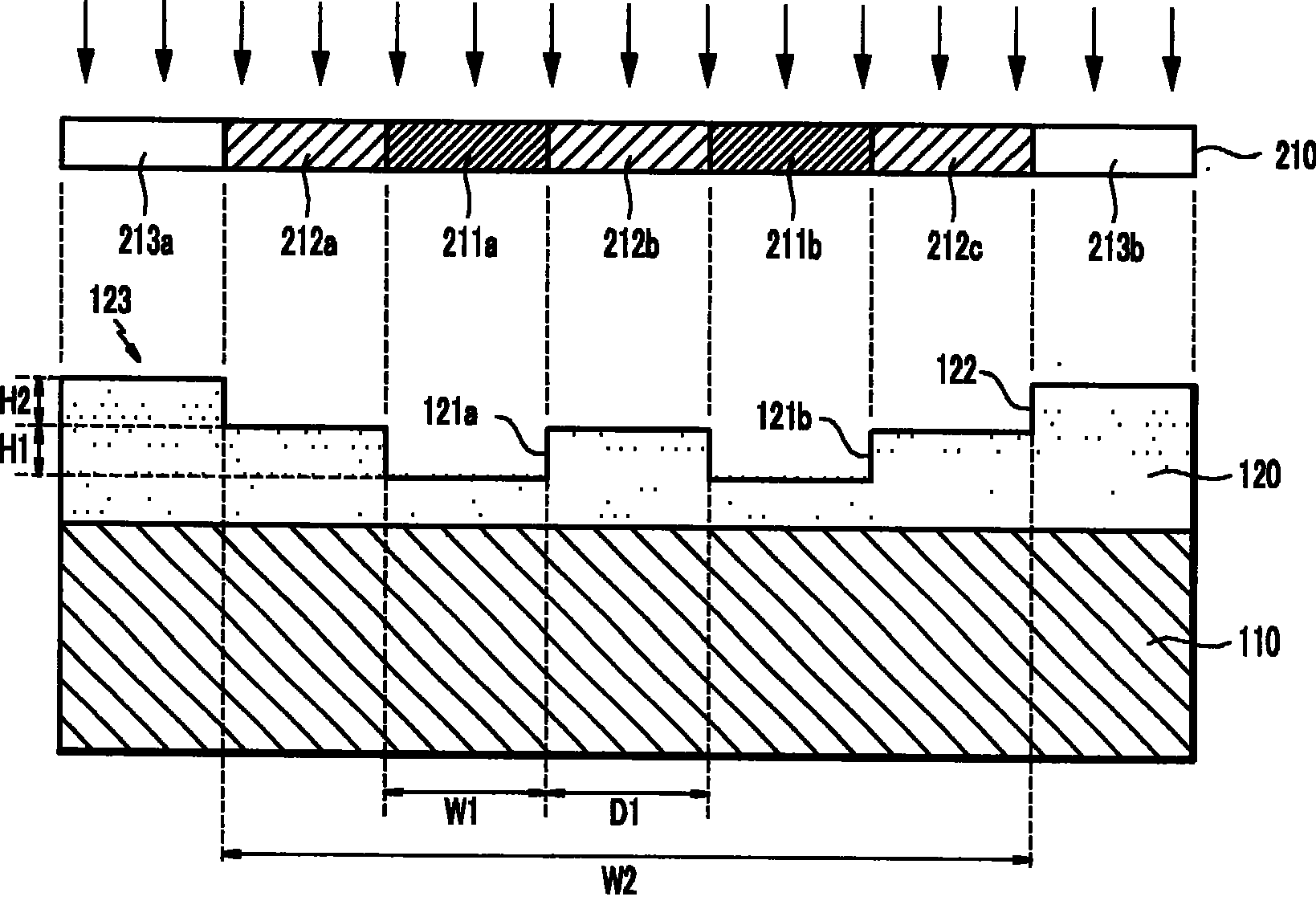

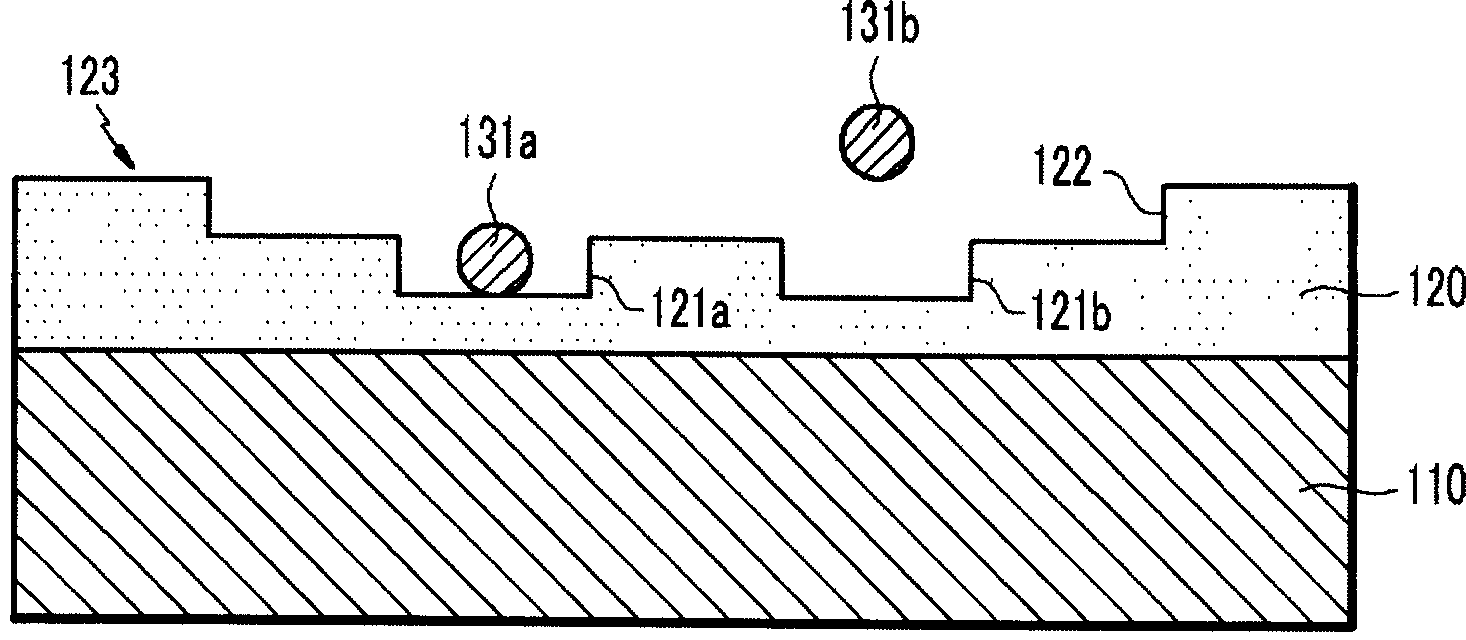

ActiveUS20060197079A1Enhance pattern precisionSimplify patterning processSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOrganic semiconductor

A method of manufacturing a thin film transistor is capable of enhancing pattern precision of an organic semiconductor layer and simplifying a patterning process. The method includes forming an organic insulating film on a substrate and forming a bank having the first and second concave portions and a third concave portion in the organic insulating film, the third concave portion being formed on the first and second concave portions. The method further includes forming a source electrode and a drain electrode in the first and second concave portions and forming an active layer in the third concave portion, the active layer contacting the source electrode and the drain electrode.

Owner:SAMSUNG DISPLAY CO LTD

Method of manufacturing thin film transistor, thin film transistor manufactured by the method, and display device employing the same

ActiveCN1832220AImprove patterning accuracySimplify the patterning processTransistorSolid-state devicesOrganic semiconductorEngineering

A method of manufacturing a thin film transistor is capable of enhancing pattern precision of an organic semiconductor layer and simplifying a patterning process. The method includes forming an organic insulating film on a substrate and forming a bank having the first and second concave portions and a third concave portion in the organic insulating film, the third concave portion being formed on the first and second concave portions. The method further includes forming a source electrode and a drain electrode in the first and second concave portions and forming an active layer in the third concave portion, the active layer contacting the source electrode and the drain electrode.

Owner:SAMSUNG DISPLAY CO LTD

Film transistor with copper wire structure and its manufacturing method

InactiveCN101090123ASimplify the patterning processGood adhesionTransistorSemiconductor/solid-state device detailsCopper wireThin layer

This invention relates to a film transistor with a copper lead structure and its manufacturing mehod, which utilizes at least one copper alloy layer and a copper layer to form a grid with multiple metal structures to improve atom arrangement among lattice interfaces and keyed jointing among atoms and reduce resistance values to suppress diffusion of Cu ions after heat process to get better electric conductance of film transistors, besides, when figuring the multiple metal thin layers, it' s only necessary to use single layer of Cu etching liquor to simplify the figuring technology.

Owner:台湾薄膜电晶体液晶显示器产业协会 +7

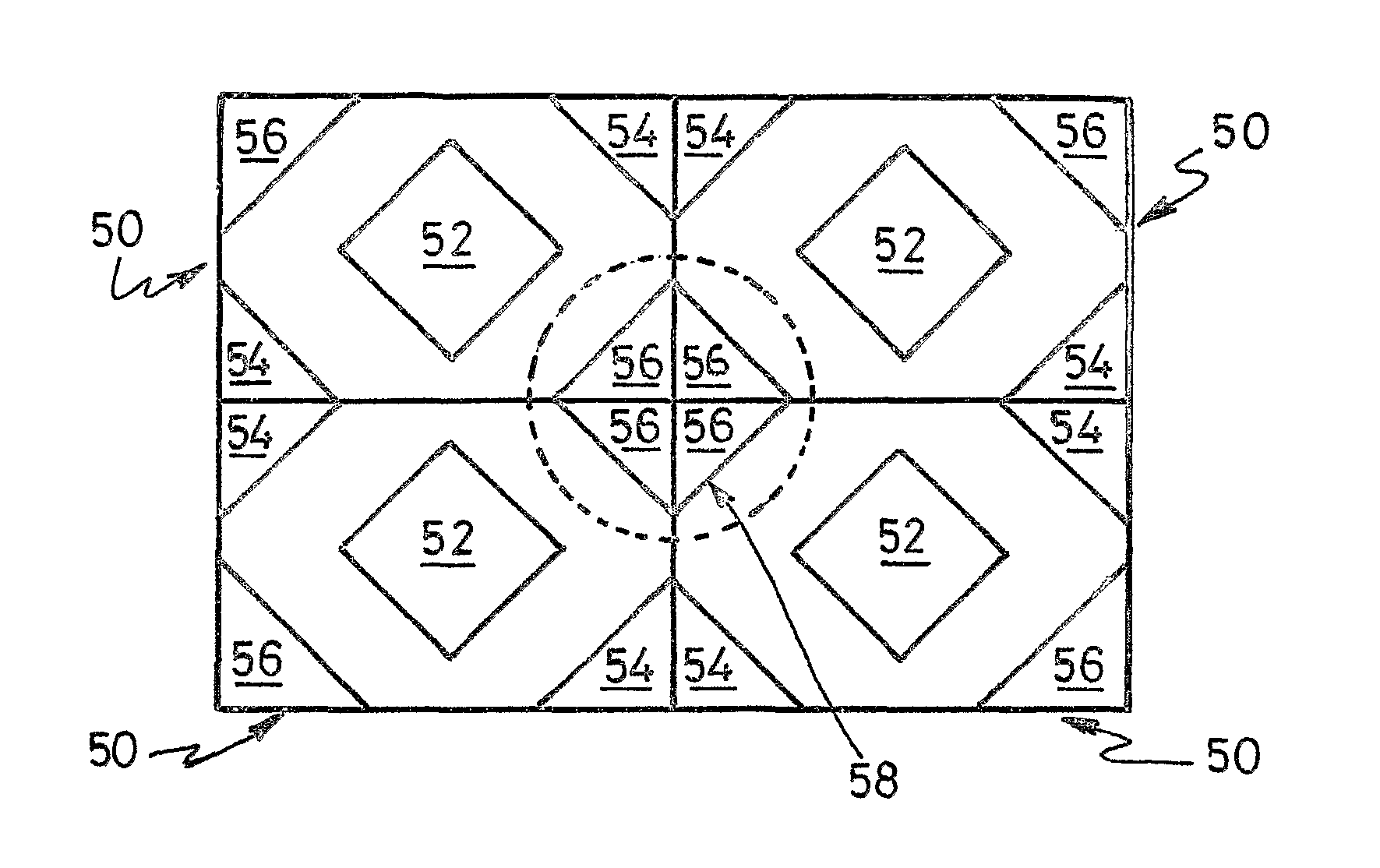

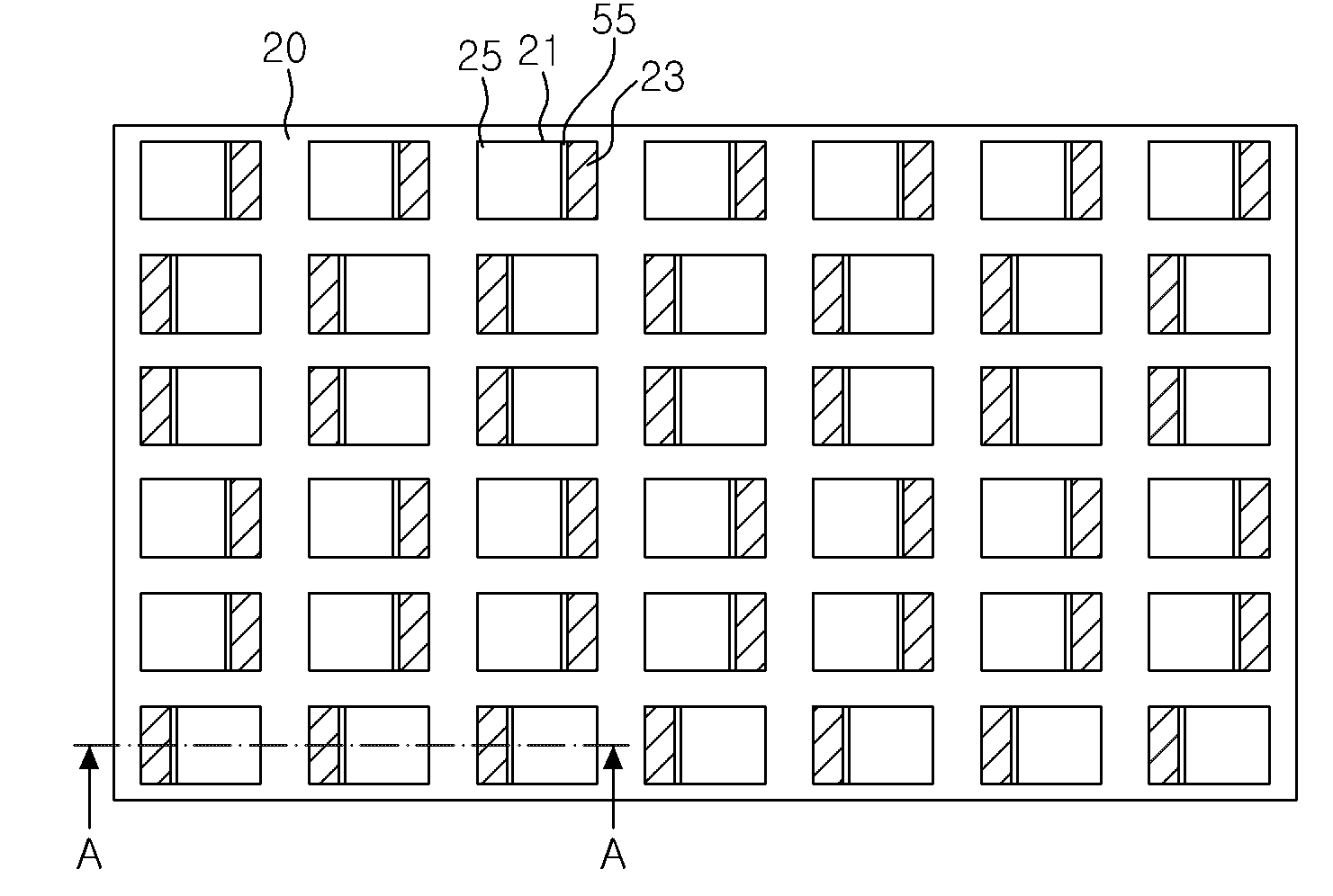

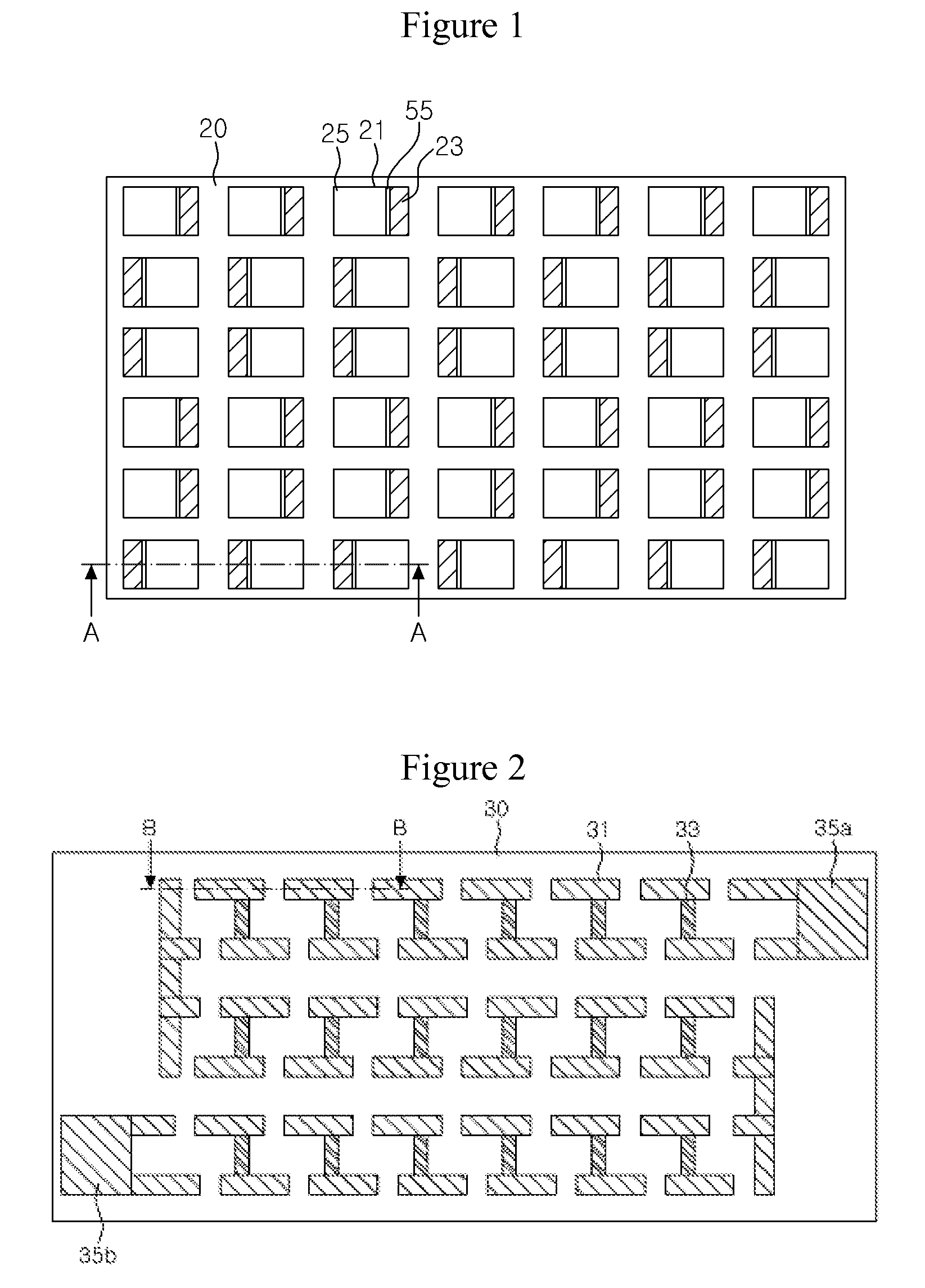

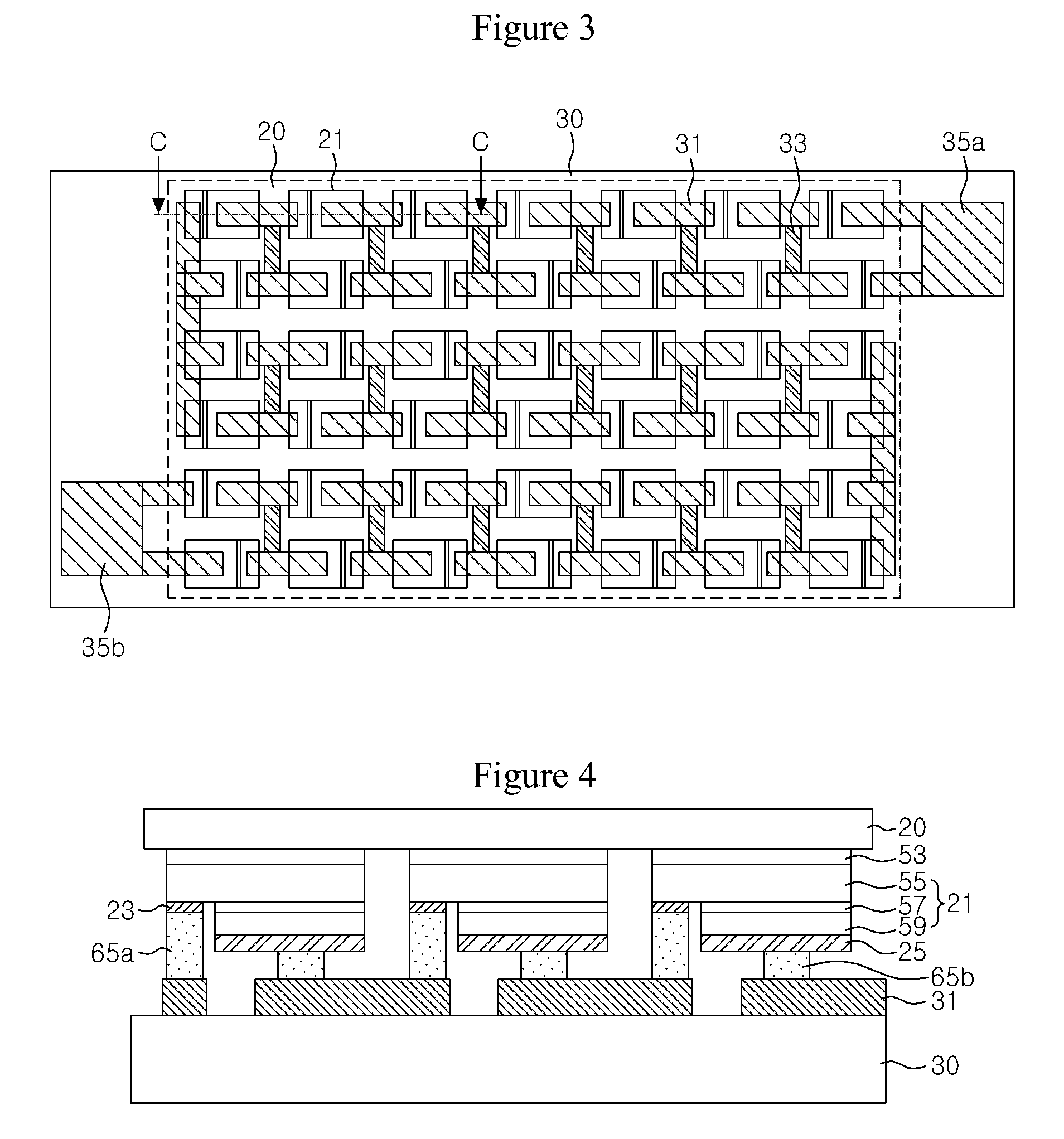

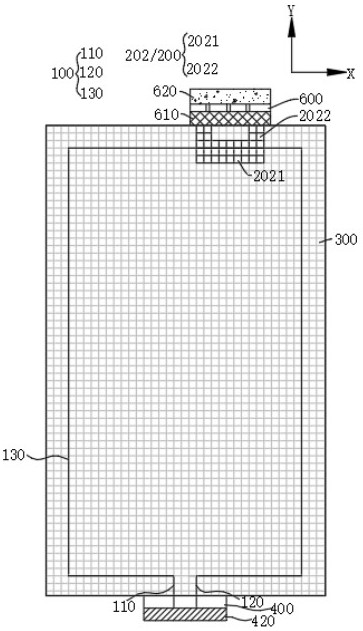

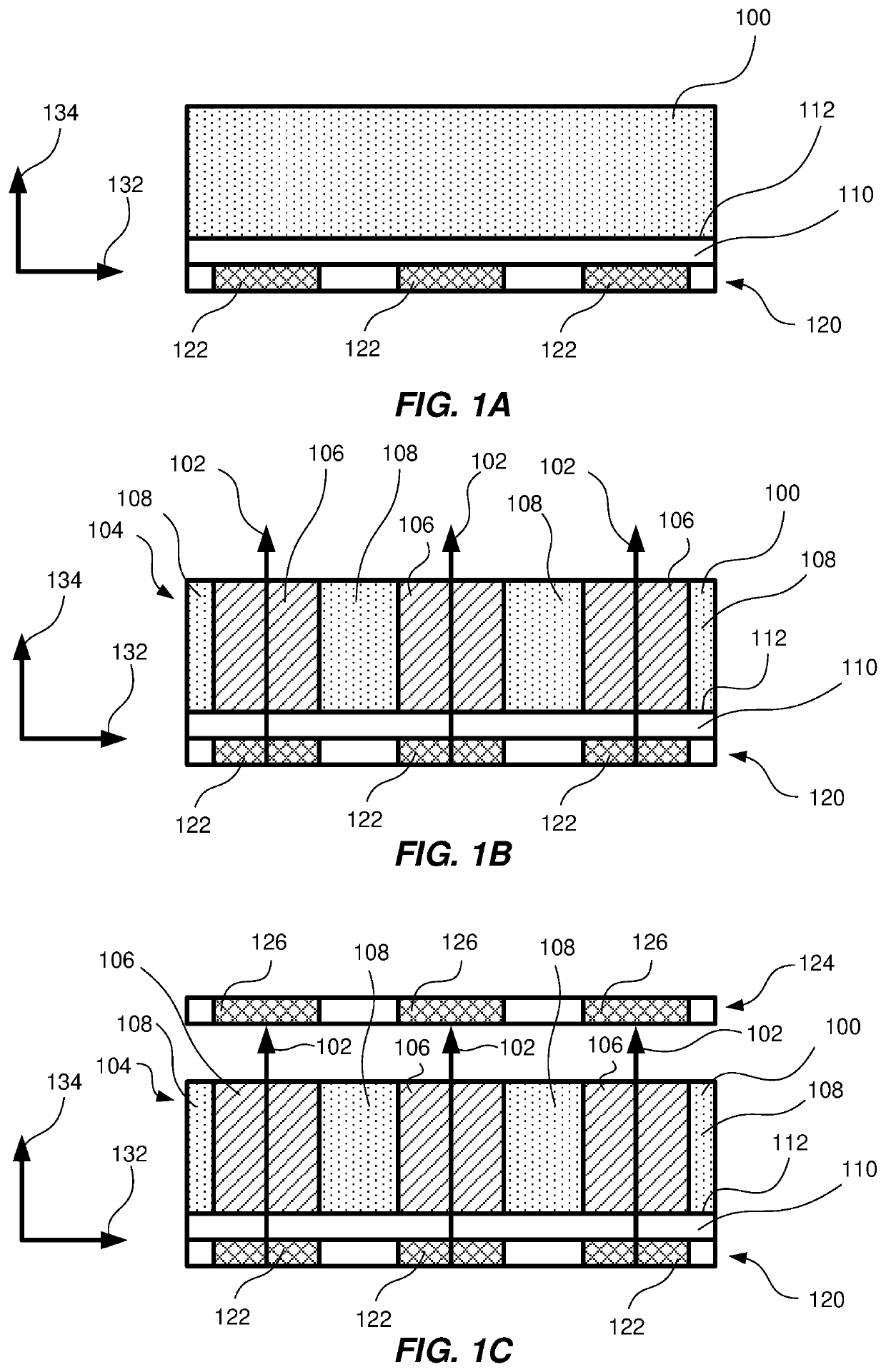

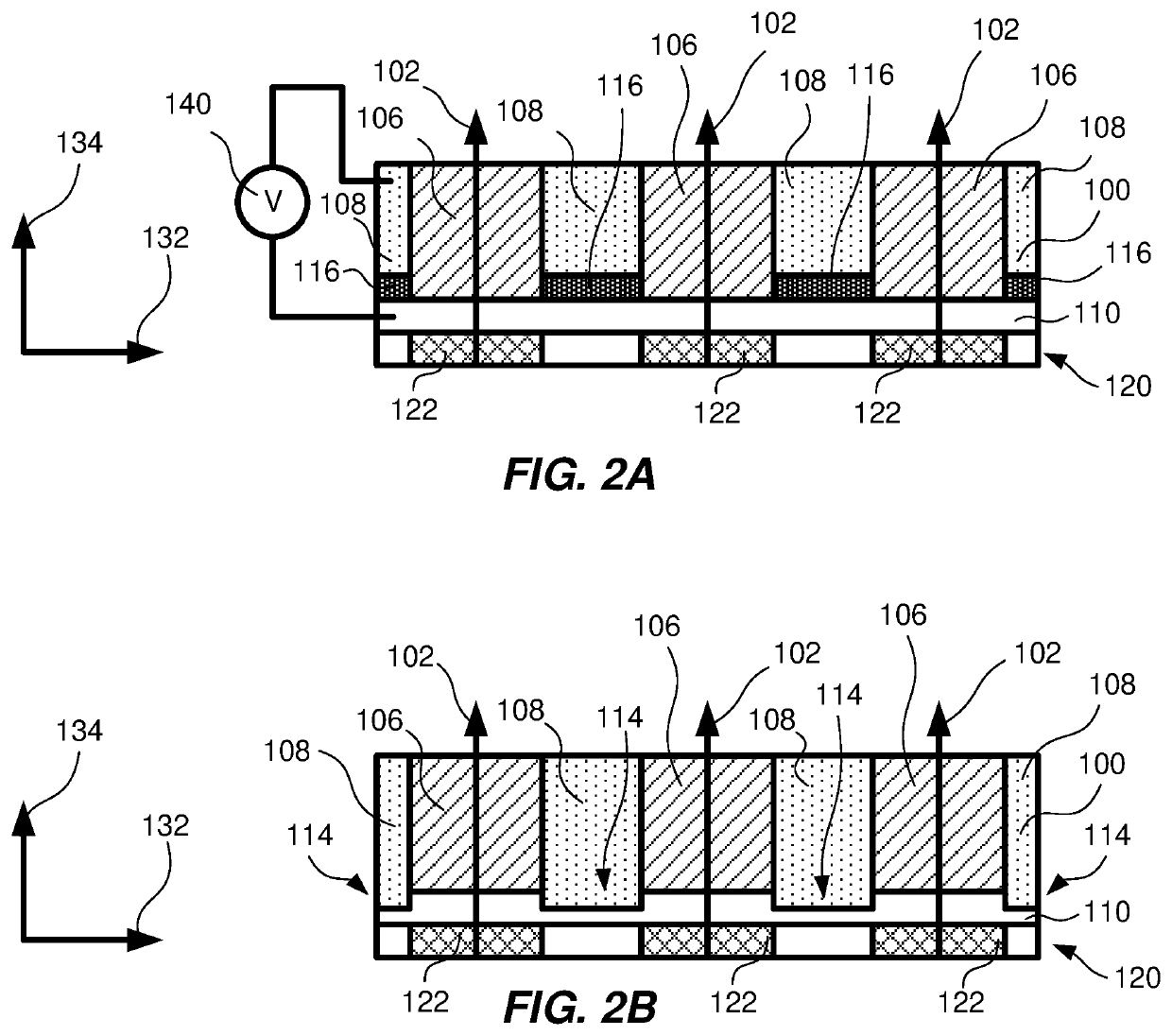

Light emitting device for ac operation

InactiveUS20100032692A1Accelerated dissipationPrevent excessive reverse voltageElectroluminescent light sourcesSolid-state devicesOvervoltageAC power

An AC light emitting device, in which a plurality of light emitting cells formed on a substrate are flip-bonded to a submount to be driven under an AC power source is disclosed. The light emitting device comprises a first serial array of light emitting cells, and a second serial array of light emitting cells, wherein the second serial array is connected in reverse parallel to the first serial array. Meanwhile, bonding patterns are formed on a submount substrate, and the light emitting cells of the first and second serial arrays are flip-bonded to the bonding patterns. Further, node connecting patterns are formed on the submount substrate, and connect the bonding patterns such that nodes corresponding to each other provided in the first and second serial arrays are electrically connected to each other. Accordingly, it is possible to provide an AC light emitting device which can prevent overvoltage from being applied to light emitting cells in the array to which reverse voltage is applied by bonding patterns and node connecting patterns formed on a submount substrate, thereby protecting the light emitting cells.

Owner:SEOUL VIOSYS CO LTD

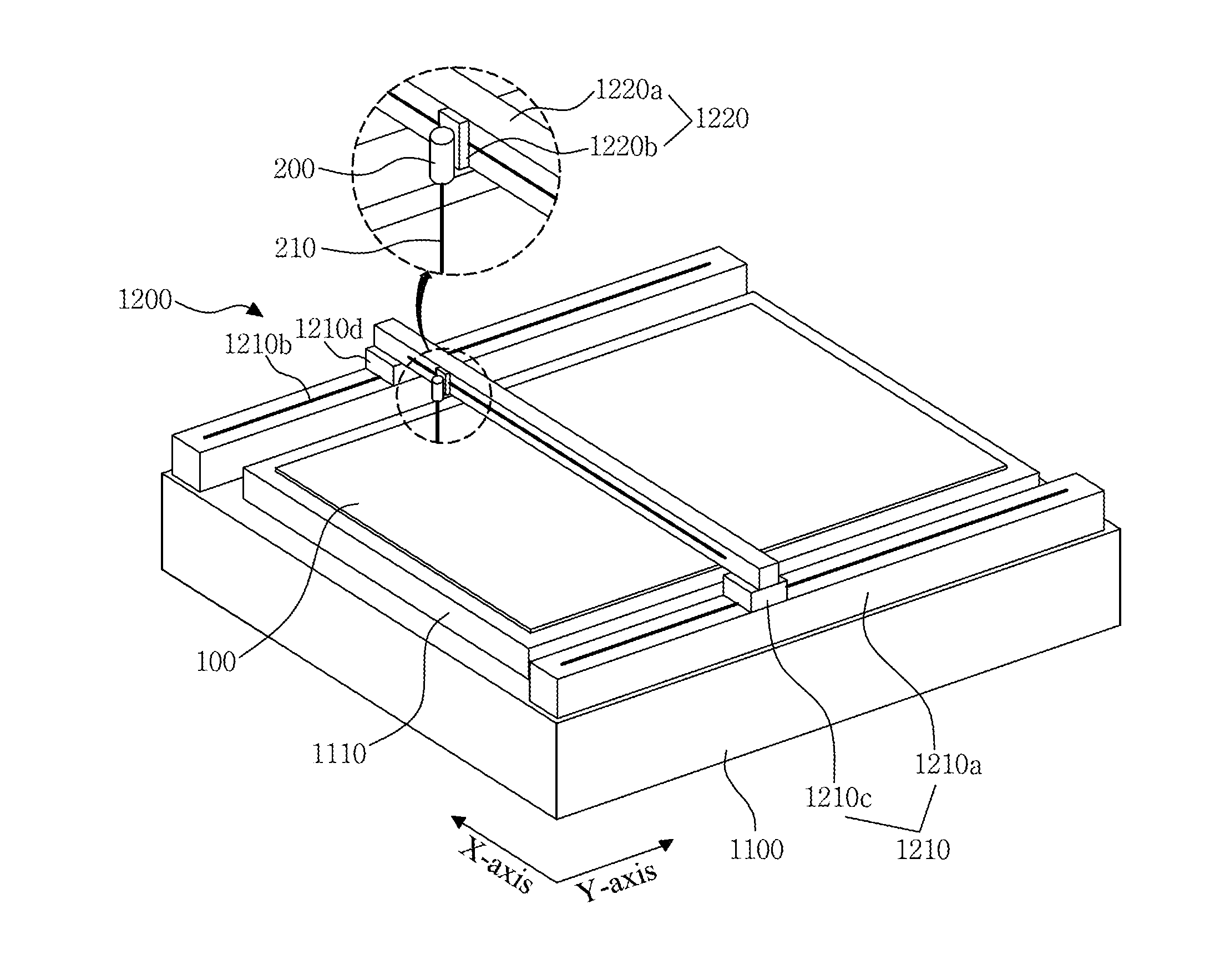

Method and Apparatus for Manufacturing Thin-Film Transistor

ActiveUS20110136303A1Avoid damageShorten production timeSolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactLaser patterning

A method and apparatus of fabricating a thin film transistor is disclosed, which patterns an ohmic contact layer by a laser patterning process so that it is capable of preventing a semiconductor layer from being damaged, and reducing fabrication time, wherein the method comprises forming a gate electrode pattern on a substrate; forming a gate insulating layer on the gate electrode pattern; sequentially forming a semiconductor layer pattern and an ohmic contact layer pattern on the gate insulating layer; forming source and drain electrode patterns on the ohmic contact layer pattern, wherein the source and drain electrode patterns are provided at a fixed interval therebetween; and removing the ohmic contact layer pattern exposed between the source and drain electrode patterns through the use of laser.

Owner:MOOHAN

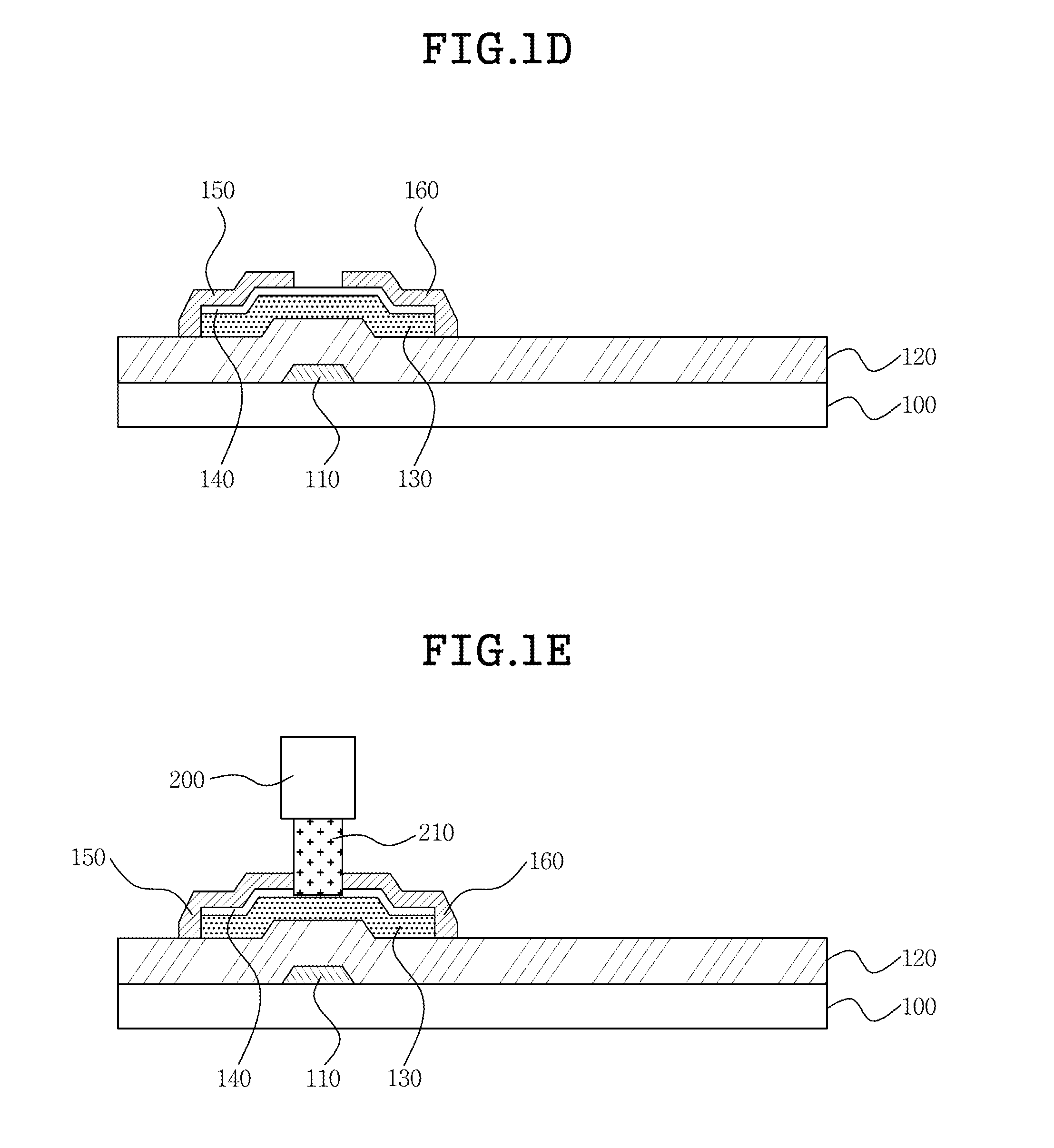

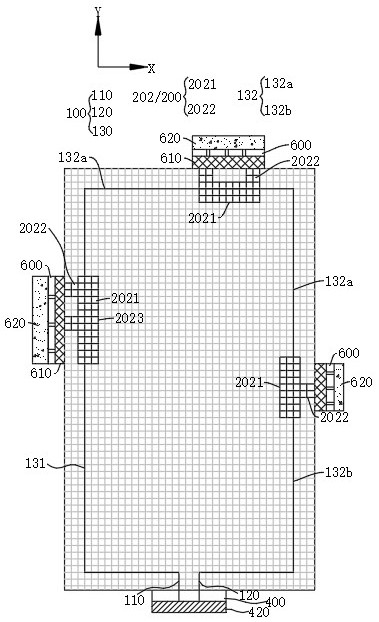

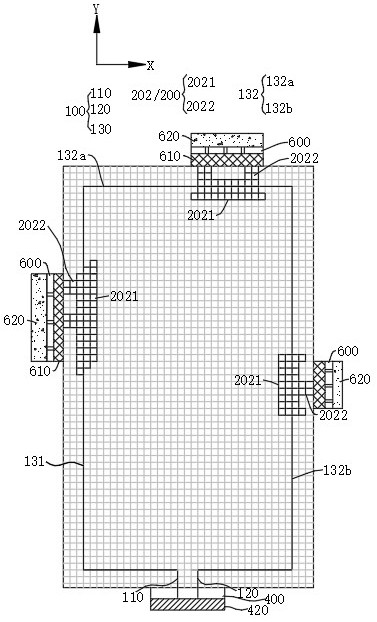

Display device and method of fabricating the same

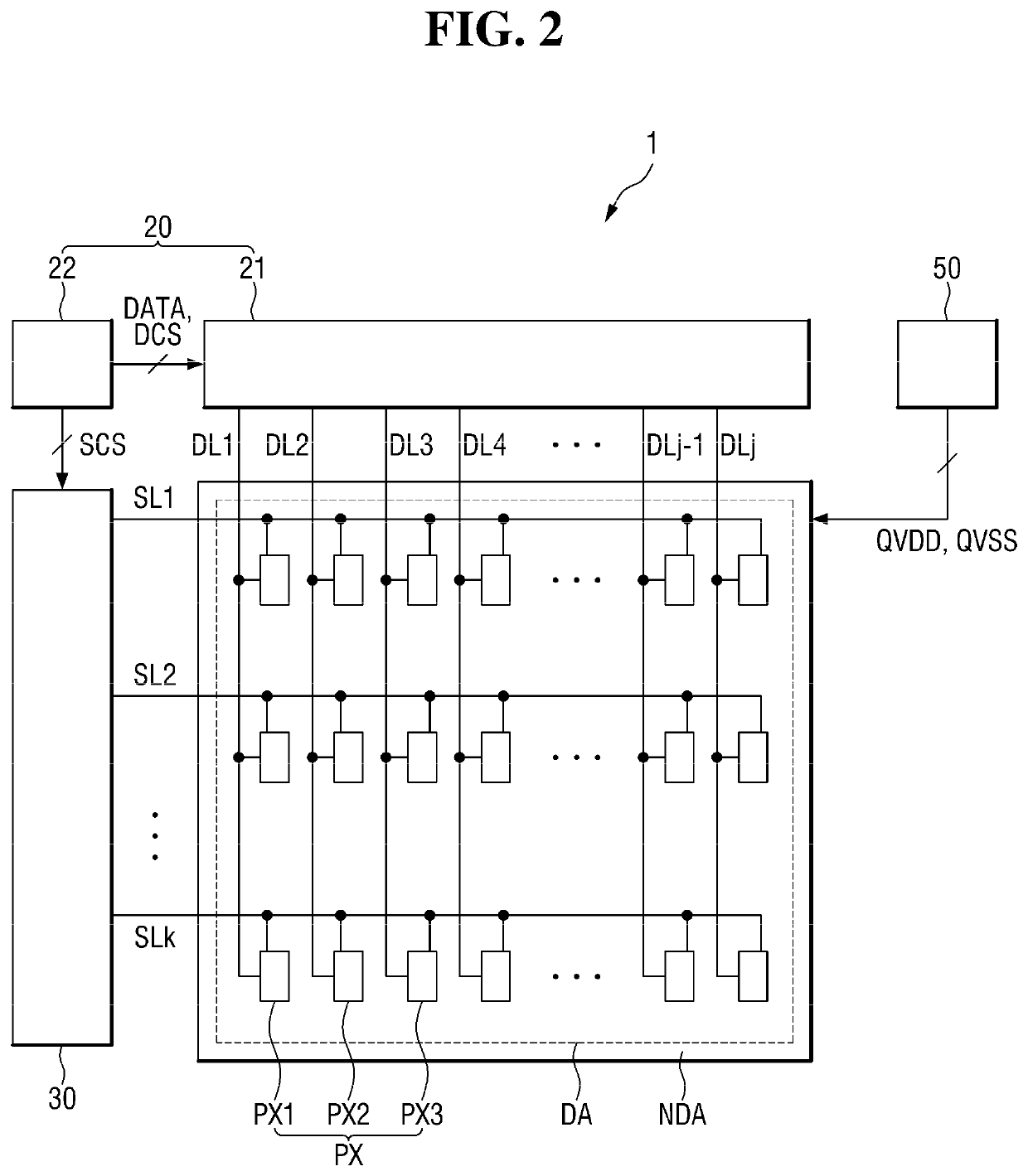

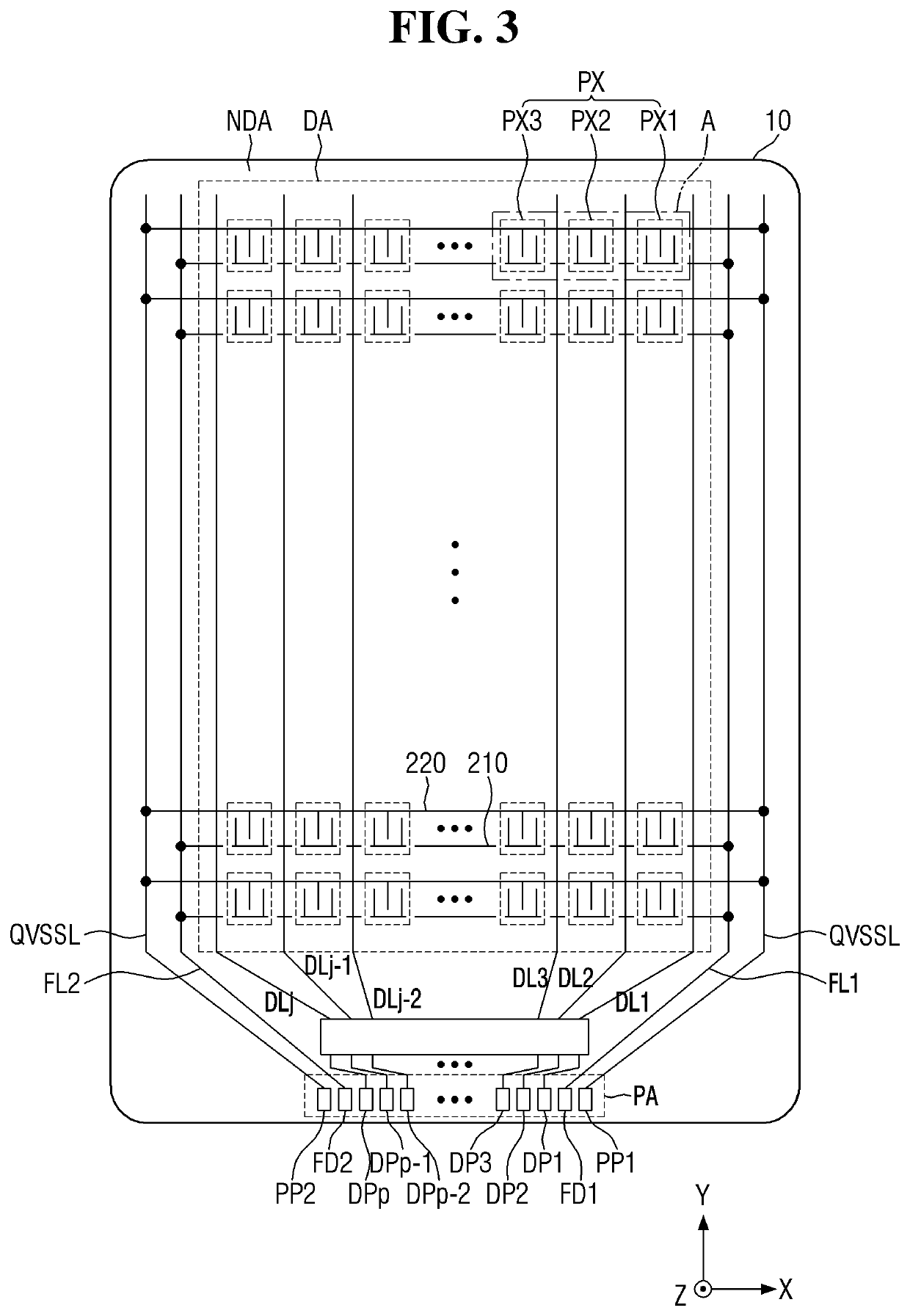

ActiveUS20200273397A1High precisionReduce voltage dropStatic indicating devicesSolid-state devicesElectrically conductiveData lines

A display device includes a light-emitting diode including a first conductivity-type semiconductor, an active layer, and a second conductivity-type semiconductor; a first voltage line to which a first voltage is applied; a second voltage line to which a second voltage is applied; a first transistor including a source electrode electrically connected to the first voltage line and a drain electrode electrically connected to a first electrode of the light-emitting diode and to the first conductivity-type semiconductor; a second transistor including a drain electrode electrically connected to a gate electrode of the first transistor and a source electrode electrically connected to a data line to apply a data signal; a capacitor electrically connected to the gate electrode of the first transistor and the first electrode; and a third transistor including a source electrode electrically connected to the second voltage line and a drain electrode electrically connected to the first electrode.

Owner:SAMSUNG DISPLAY CO LTD

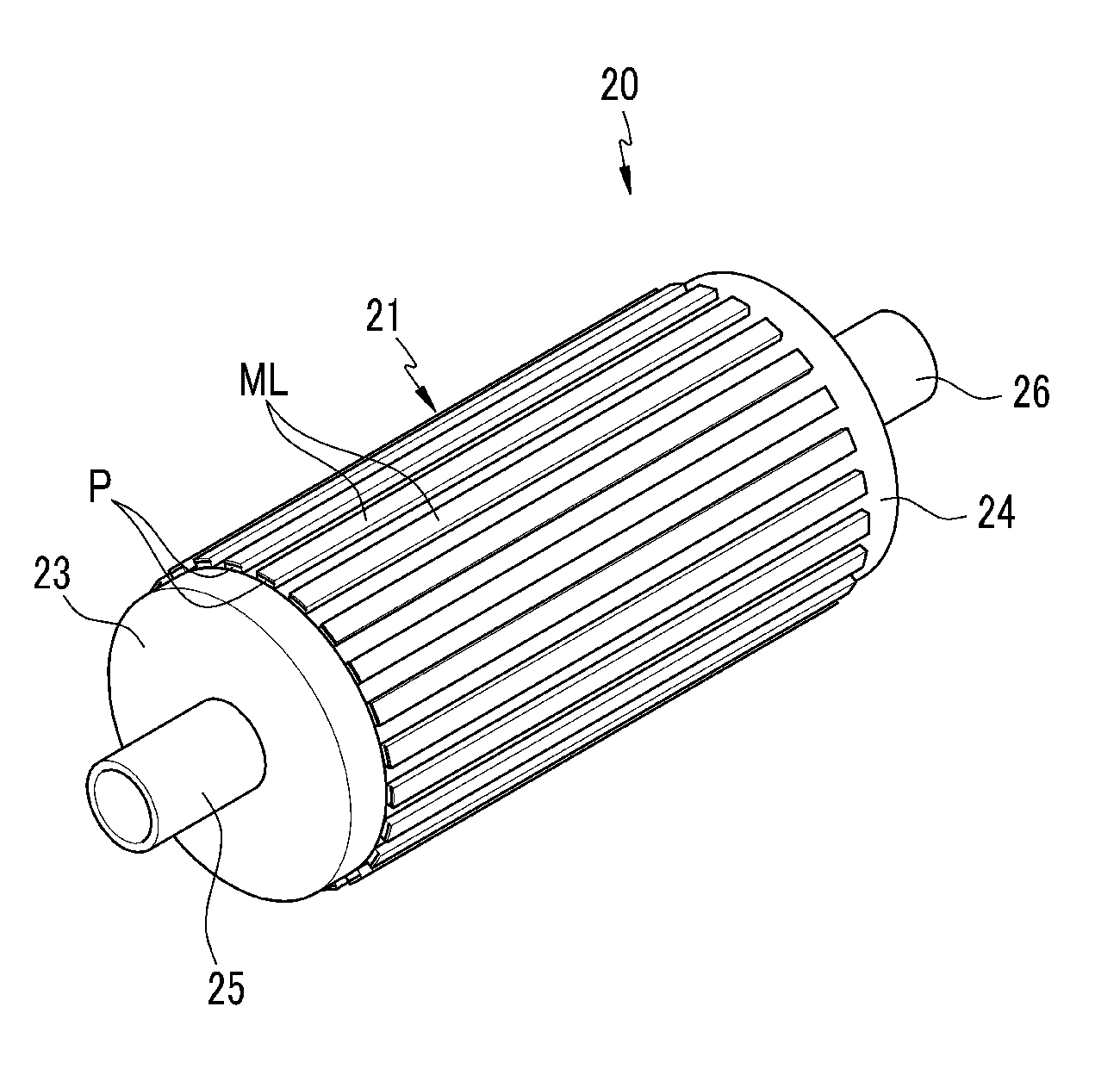

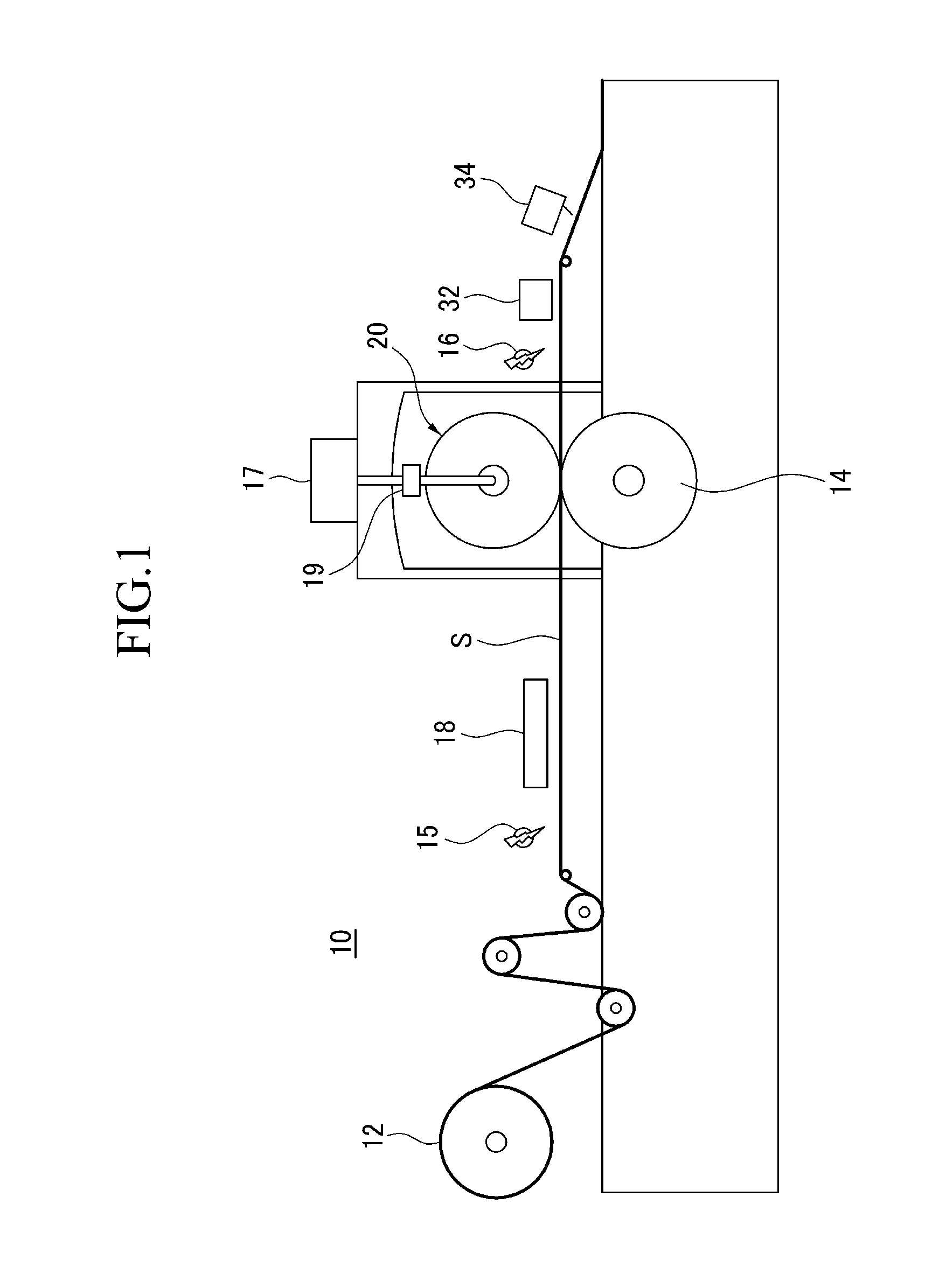

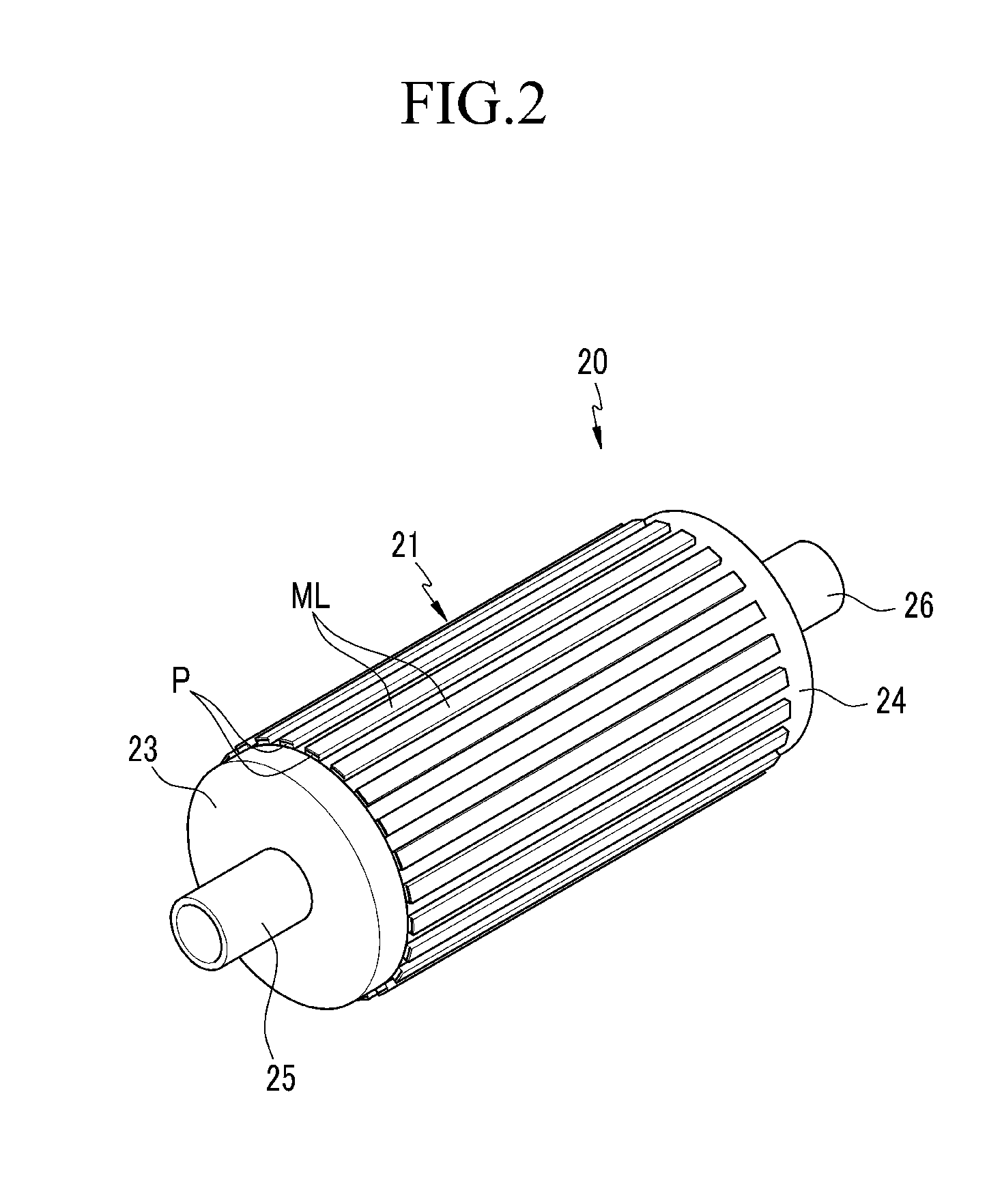

Roll imprinting apparatus

InactiveUS20120204745A1Simplify patterning processSimplify the patterning processNanoinformaticsPhotomechanical apparatusBlock layerBlocking layer

An exemplary embodiment of the present invention relates to roll imprint that simplifies a substrate patterning process by simultaneously performing a process for imprinting a pattern to a coating layer and a process for curing the pattern.A roll imprinting apparatus according to an exemplary embodiment of the present invention performs an imprinting process on a transferred substrate. The roll imprinting apparatus includes: a pattern roll imprinting a pattern formed in the surface thereof to the substrate while rotating; and a press roll pressing the substrate while rotating in the opposite side of the pattern roll, interposing the substrate therebetween, and the pattern roll includes a cylinder and a UV lamp. The cylinder is formed of a transparent material and has an inner space formed thereinside and the pattern provided in the external surface thereof, and has a ultraviolet (UV) ray block layer selectively formed in the patterned portion or a portion

Owner:KOREA INST OF MASCH & MATERIALS

Fabrication method of liquid crystal display device

InactiveUS7569153B2Simplify the patterning processTransistorAfter-treatment detailsResistLiquid-crystal display

Owner:LG DISPLAY CO LTD

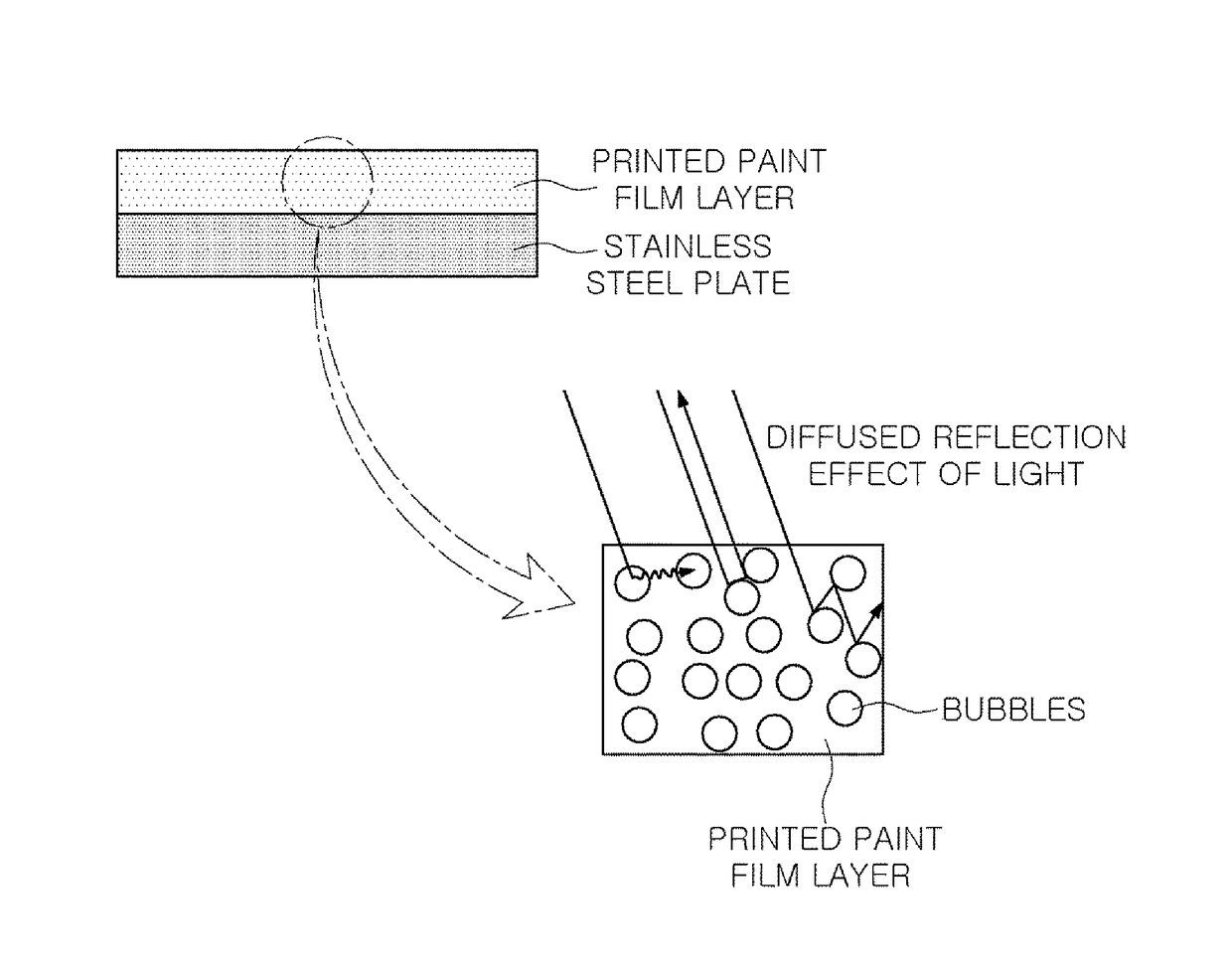

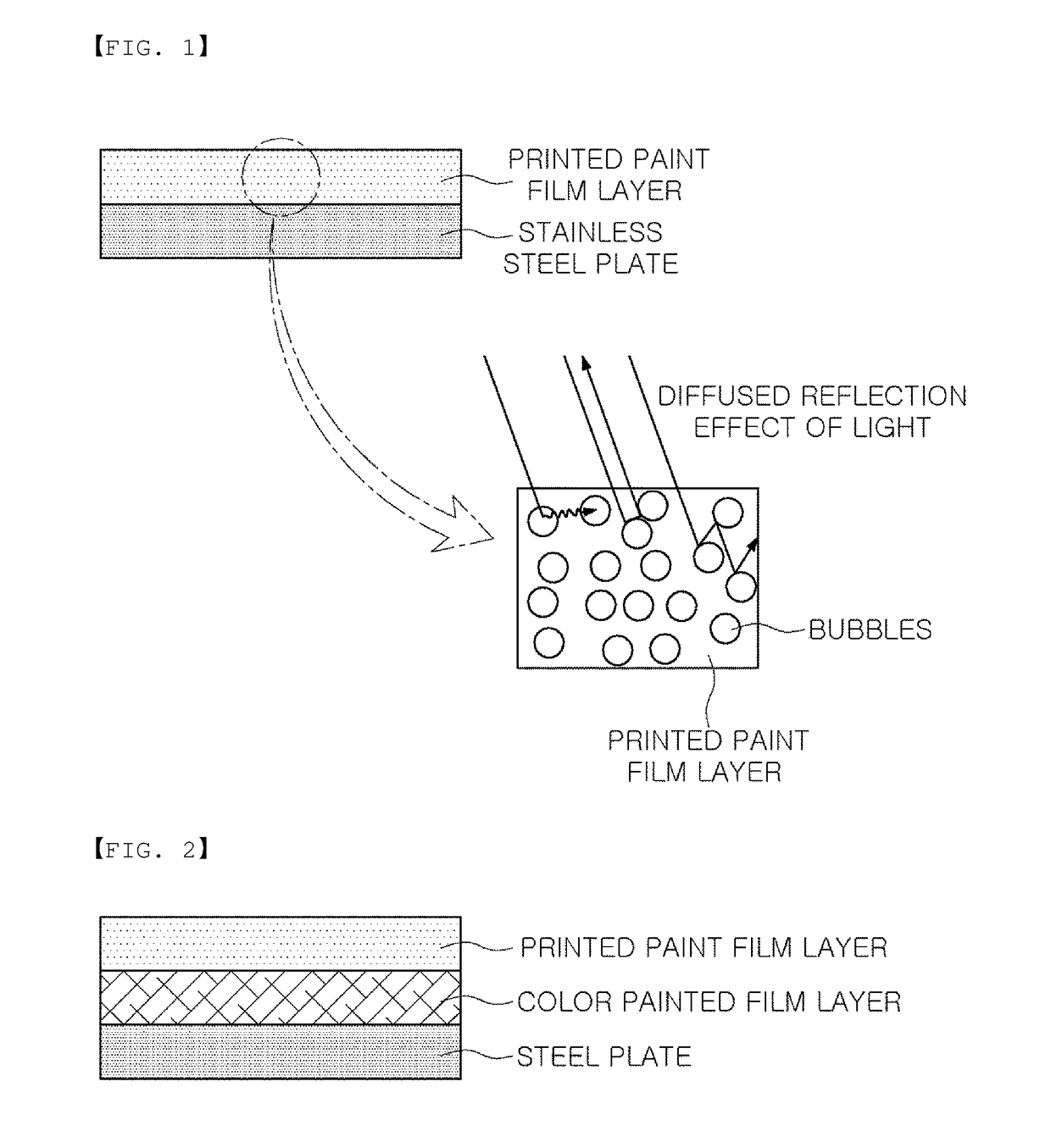

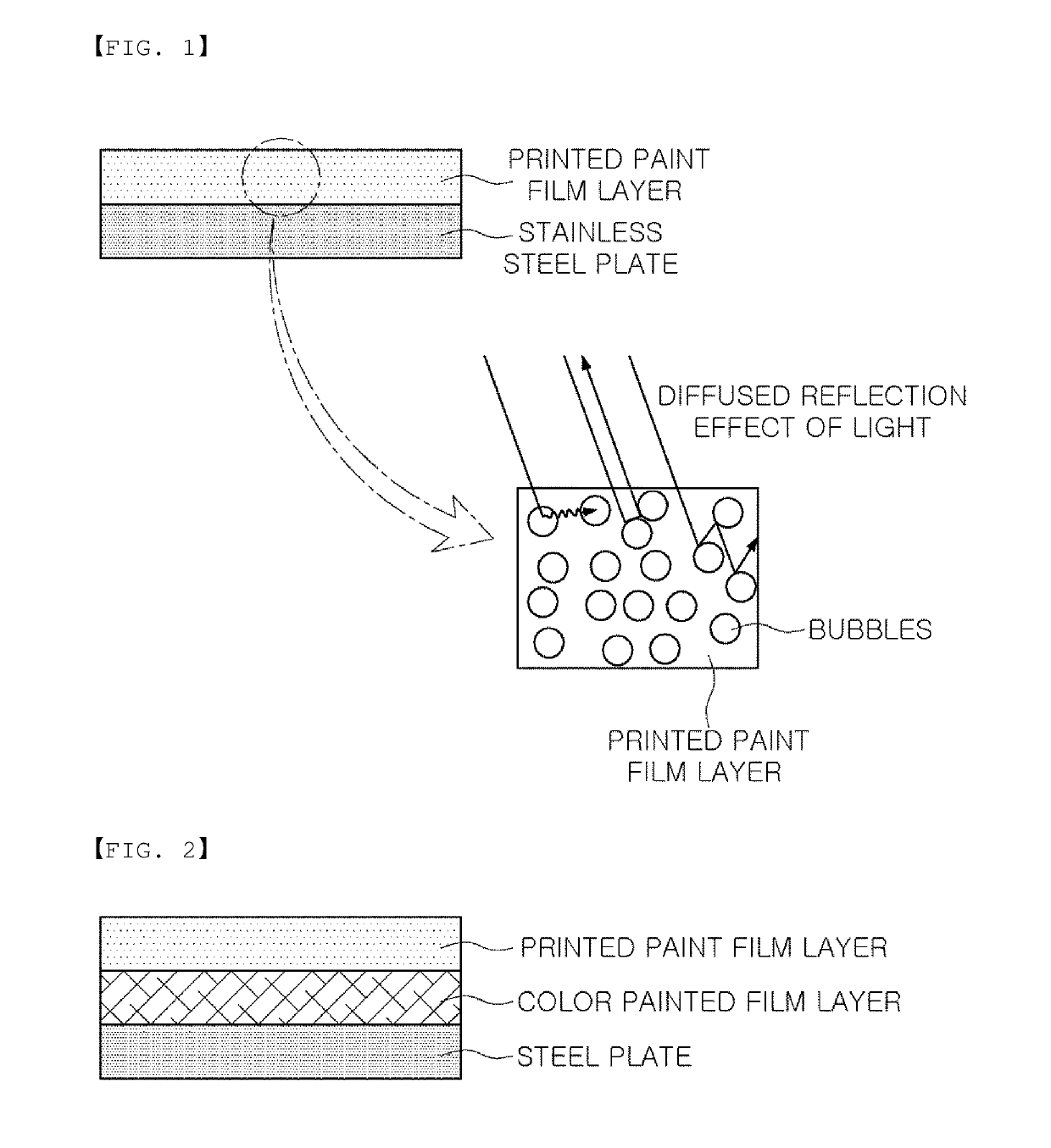

Method for manufacturing transparent pattern print steel plate

ActiveUS20170354991A1Low operating costHigh hardnessDuplicating/marking methodsPretreated surfacesSteel platesOptoelectronics

A method of manufacturing a transparent pattern printed steel plate includes forming a printed paint film layer by jetting transparent ink onto at least one surface of a steel plate, and curing the printed paint film layer with ultraviolet light to form a cured printed paint film layer. Further, a method of manufacturing a transparent pattern printed steel plate includes preparing a steel plate having a color painted film layer formed on at least one surface thereof, forming a printed paint film layer by jetting transparent ink onto the color painted film layer, and curing the printed paint film layer to form a cured printed paint film layer.

Owner:POSCO

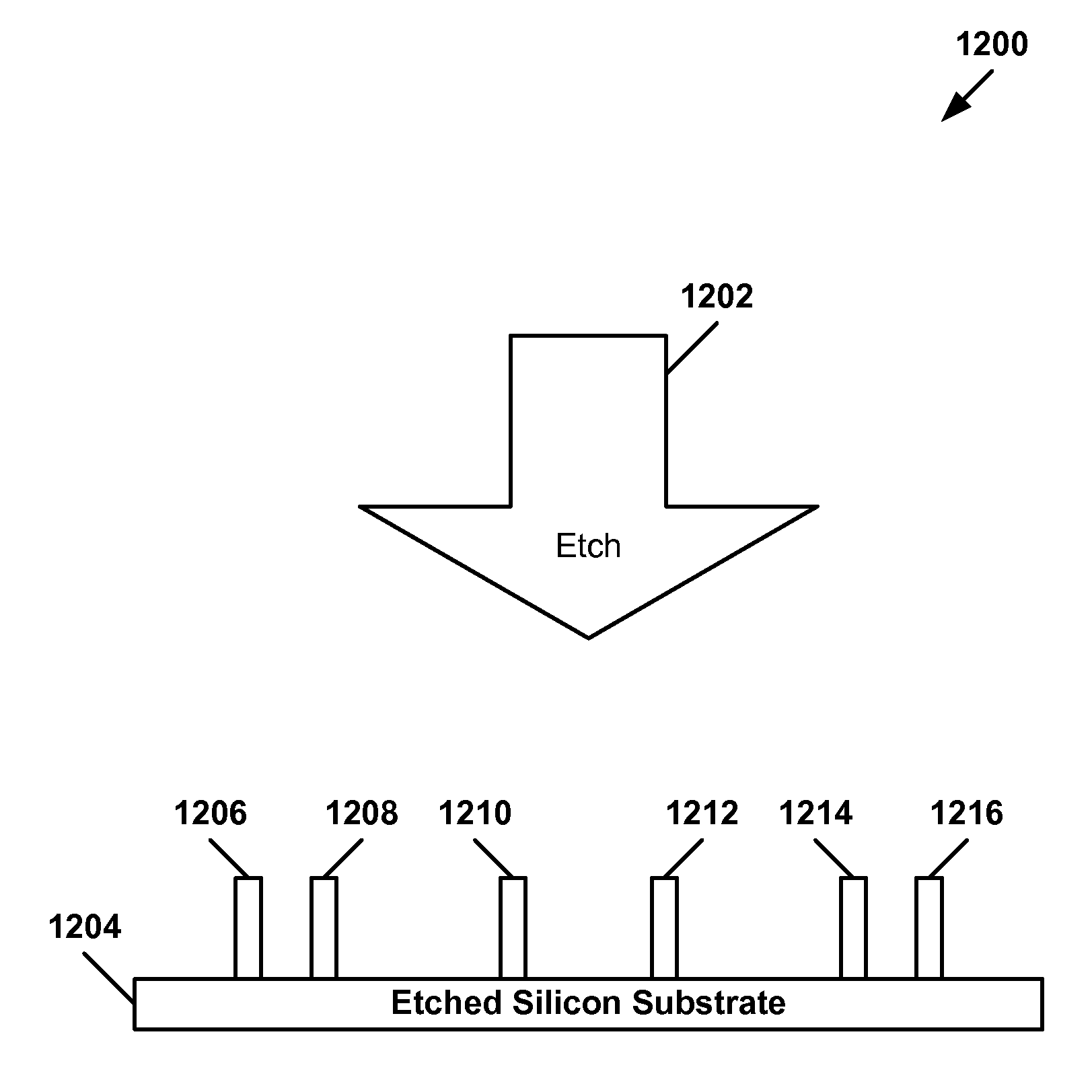

Method for fabricating hole pattern in semiconductor device

InactiveUS20120276745A1Simplify the patterning processSecure process marginSemiconductor/solid-state device manufacturingCapacitorsSemiconductorInorganic layer

A method for fabricating a hole pattern in a semiconductor device includes forming a first organic layer over an etch layer, forming a first inorganic layer pattern over the first organic layer, etching the first organic layer using the first inorganic layer pattern as an etching barrier, forming a second organic layer over the first organic layer, forming a second inorganic layer pattern over the second organic layer, where the second inorganic layer pattern crosses the first inorganic pattern, etching the first and second organic layers using the second inorganic layer pattern as an etching barrier, and etching the etch layer using the etched first and second organic layers as an etch barrier to form a hole pattern.

Owner:SK HYNIX INC

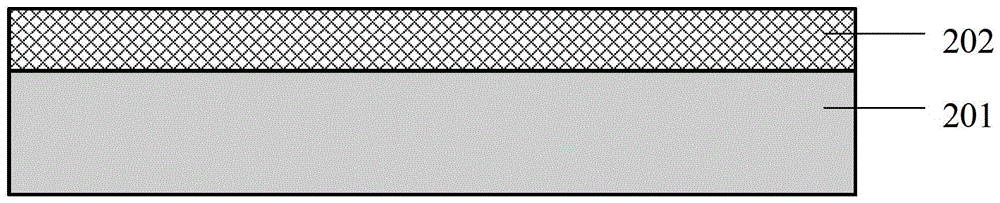

Composite transparent conductive film and preparation method thereof

ActiveCN107275007AImprove conductivityAchieve preparationMaterial nanotechnologyConductive layers on insulating-supportsThin metalLithographic artist

The present invention discloses a composite transparent conductive film and a preparation method thereof. The composite transparent conductive film is formed by stacking a transparent oxide layer and a thin metal layer, wherein the thin metal layer is located under the transparent oxide layer, the thickness of the thin metal layer is 3-30nm, the thin metal layer is in a transparent state, and the thin metal layer has nanopores. The preparation method comprises: the step (1), preparing the thin metal layer; the step (2), preparing the transparent oxide layer to form a required pattern, putting the required pattern into liquid after annealing processing to remove the thin metal layer which is not covered by the transparent oxide layer, storing the transparent oxide layer and the thin metal layer which is covered by the transparent oxide layer, and realizing the patterning of the composite transparent conductive film. The patterning process does not need photo-mask lithography, the prepared composite transparent conductive film is good in resistivity and good in electricity stability, has a certain optical transmissibility, and is heat resisting, antioxidant and erosion-resistant.

Owner:SOUTH CHINA UNIV OF TECH

Organic electro-luminescence display device and method of manufacturing the same

ActiveUS20080074043A1Excellent image quality characteristicSimplify the patterning processDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceOrganic electroluminescence

Provided is an organic electro-luminescence display device. The organic electro-luminescence display device includes: a first electrode, a first charge transport pattern, an organic emission pattern, a second charge transport pattern, and a second electrode. The first charge transport pattern is formed on the first electrode, and the organic emission pattern is on the first charge transport pattern. The second charge transport pattern is formed on the organic emission pattern, and includes an insoluble material. The second electrode is formed on the second charge transport pattern.

Owner:LG DISPLAY CO LTD

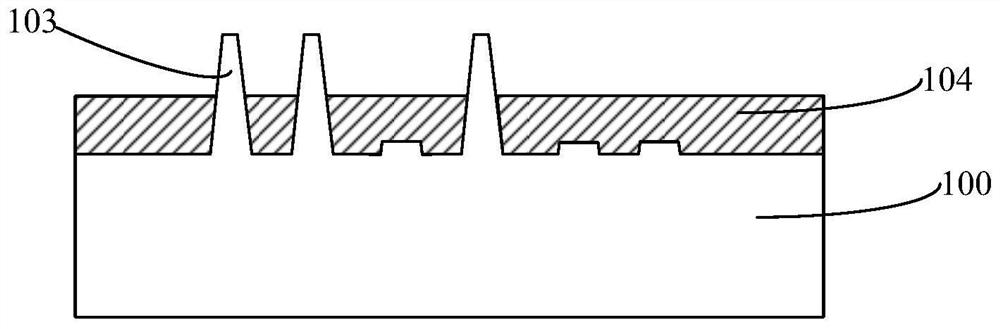

Method for manufacturing interconnection structure containing air gaps

ActiveCN102881643AIntegrity guaranteedSimple processSemiconductor/solid-state device manufacturingInterconnectionEngineering

The invention discloses a method for manufacturing an interconnection structure containing air gaps. The method includes: forming a first sacrificial layer on a substrate; forming a metal interconnection line in the first sacrificial layer; depositing and etching a second sacrificial layer to form a narrow-end-up peak structure which is connected with a sacrificial medium of the first sacrificial layer; depositing a first medium layer and removing the first medium layer of the upper surface of the second sacrificial layer so as to form a releasing opening at the top of the peak structure; removing sacrificial media of the first sacrificial layer and the second sacrifical layer; and depositing a second medium layer to form the air gaps. By the method, sealing integrity of the air gaps can be guaranteed and the interconnection structure has a larger process window.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Method of producing an electron emission device, method of producing an electron source, method of producing an image display device, and method of driving an electron emission device

InactiveUS7524227B2Simple structureLow costSparking plugsDischarge tube luminescnet screensElectron sourceDisplay device

A method of producing an electron emission device having a low threshold electric field needed to emit electrons without unintentional electron emission includes a first step of preparing a first conductive film, second conductive film, and a material which constitutes an electron emission part connected to the first conductive film, and a second step of setting a threshold electric field strength, which is needed to start electron emission in a situation where a higher electric potential is applied to the first conductive film than that applied to the second conductive film, to a value greater than a threshold electric field strength, which is needed to start electron emission in a situation where a higher electric potential is applied to the second conductive film than that applied to the first conductive film.

Owner:CANON KK

Wireless communication structure, display panel and wireless communication device

ActiveCN114530693ASimplify the patterning processImprove production efficiencyLoop antennas with ferromagnetic coreSimultaneous aerial operationsTelecommunicationsCommunication device

The embodiment of the invention provides a wireless communication structure, a display panel and wireless communication equipment, and the wireless communication structure comprises a loop structure which comprises a first connection end, a second connection end and a coil body, and at least part of the coil body is connected between the first connection end and the second connection end; and the antenna is connected to the coil body. According to the embodiment of the invention, the antenna is connected to the coil body of the loop structure, so that the loop structure and the antenna can be arranged in a limited space, the optical performance of a display screen can be better ensured, the preparation efficiency of the wireless communication structure can be improved, and the preparation cost can be reduced.

Owner:YUNGU GUAN TECH CO LTD

Semiconductor structure and forming method thereof

PendingCN111834222AAvoid formingAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureEngineering

The invention provides a semiconductor structure and a forming method thereof. The method comprises: providing a substrate, wherein the substrate comprising a first region, a plurality of second regions and a plurality of third regions, the first region is located between two adjacent third regions, two sides of the first region are respectively provided with one second region, and each second region is located between the first region and the third region; forming a pattern structure on the substrate, wherein the pattern structure comprises a first pattern layer located on the first region, asecond pattern layer located on the second region and a third pattern layer located on the third region, the first pattern layer and the second pattern layer are discrete from each other, and the second pattern layer and the third pattern layer are discrete from each other; removing the second pattern layer; and after the second pattern layer is removed, etching the substrate by taking the firstpattern layer and the third pattern layer as masks to form a base, a first fin part located on the base and a second fin part located on the base, wherein the first fin part is formed by etching by taking the first pattern layer as a mask, and the third fin part is formed by etching by taking the third pattern layer as a mask. According to the invention, the performance of the formed semiconductorstructure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A method of manufacturing an interconnect structure containing an air gap

ActiveCN102881643BIntegrity guaranteedSimple processSemiconductor/solid-state device manufacturingEngineeringInterconnection

The invention discloses a method for manufacturing an interconnection structure containing air gaps. The method includes: forming a first sacrificial layer on a substrate; forming a metal interconnection line in the first sacrificial layer; depositing and etching a second sacrificial layer to form a narrow-end-up peak structure which is connected with a sacrificial medium of the first sacrificial layer; depositing a first medium layer and removing the first medium layer of the upper surface of the second sacrificial layer so as to form a releasing opening at the top of the peak structure; removing sacrificial media of the first sacrificial layer and the second sacrifical layer; and depositing a second medium layer to form the air gaps. By the method, sealing integrity of the air gaps can be guaranteed and the interconnection structure has a larger process window.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

Method for manufacturing transparent pattern print steel plate

ActiveUS10391518B2High hardnessEasy to processDuplicating/marking methodsPretreated surfacesUltraviolet lightsOptoelectronics

A method of manufacturing a transparent pattern printed steel plate includes forming a printed paint film layer by jetting transparent ink onto at least one surface of a steel plate, and curing the printed paint film layer with ultraviolet light to form a cured printed paint film layer. Further, a method of manufacturing a transparent pattern printed steel plate includes preparing a steel plate having a color painted film layer formed on at least one surface thereof, forming a printed paint film layer by jetting transparent ink onto the color painted film layer, and curing the printed paint film layer to form a cured printed paint film layer.

Owner:POHANG IRON & STEEL CO LTD

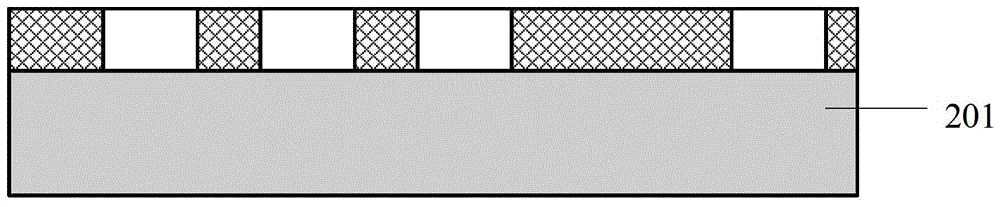

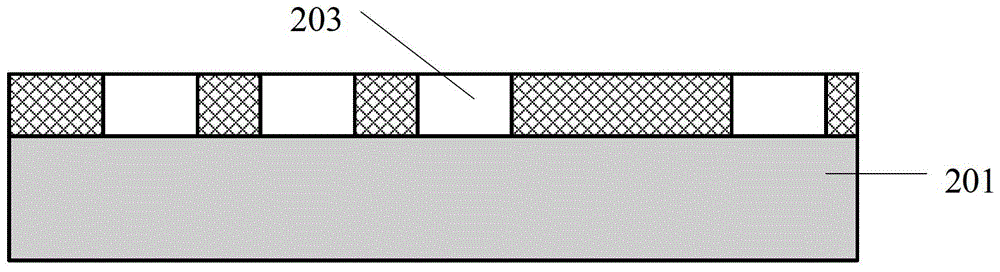

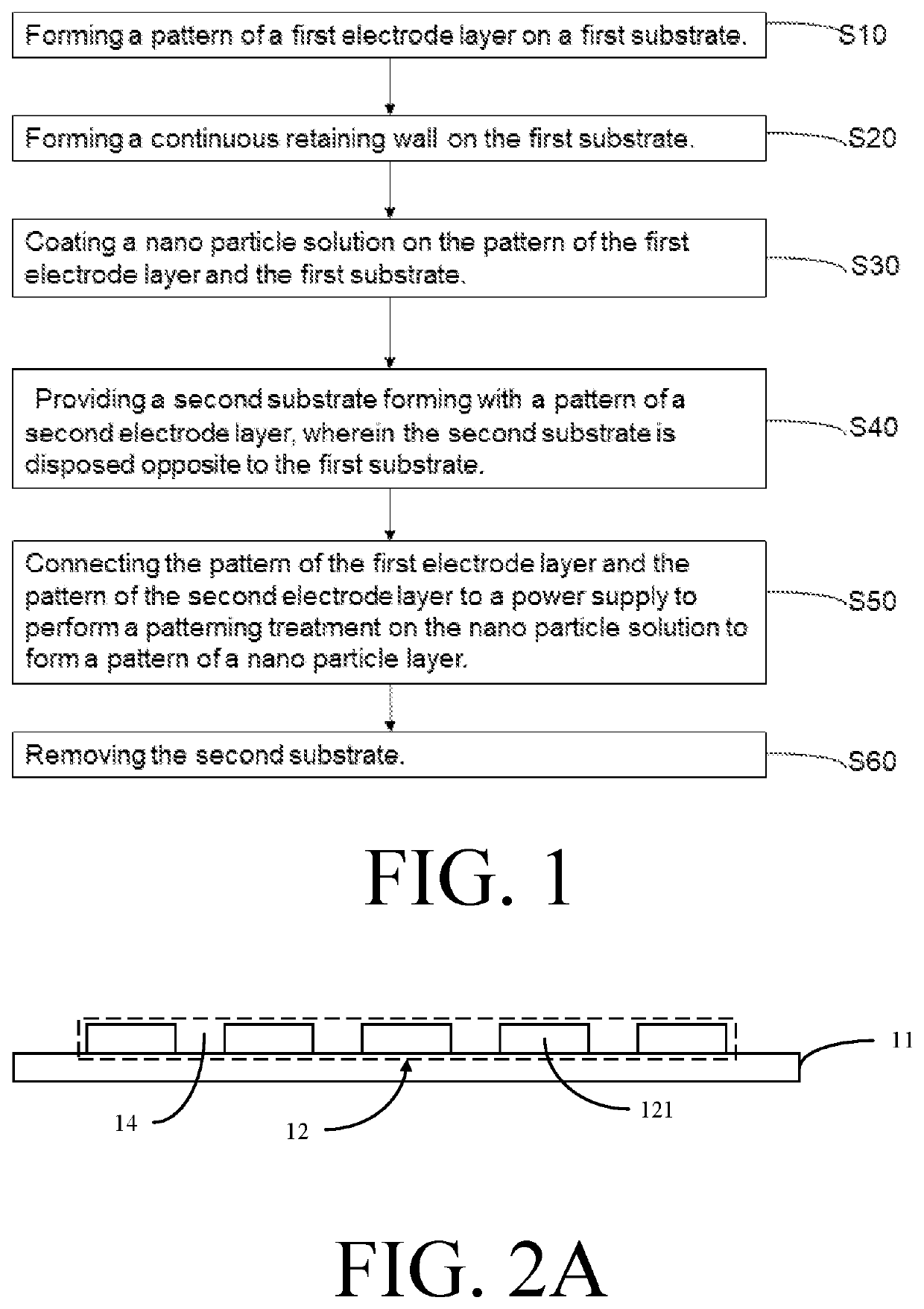

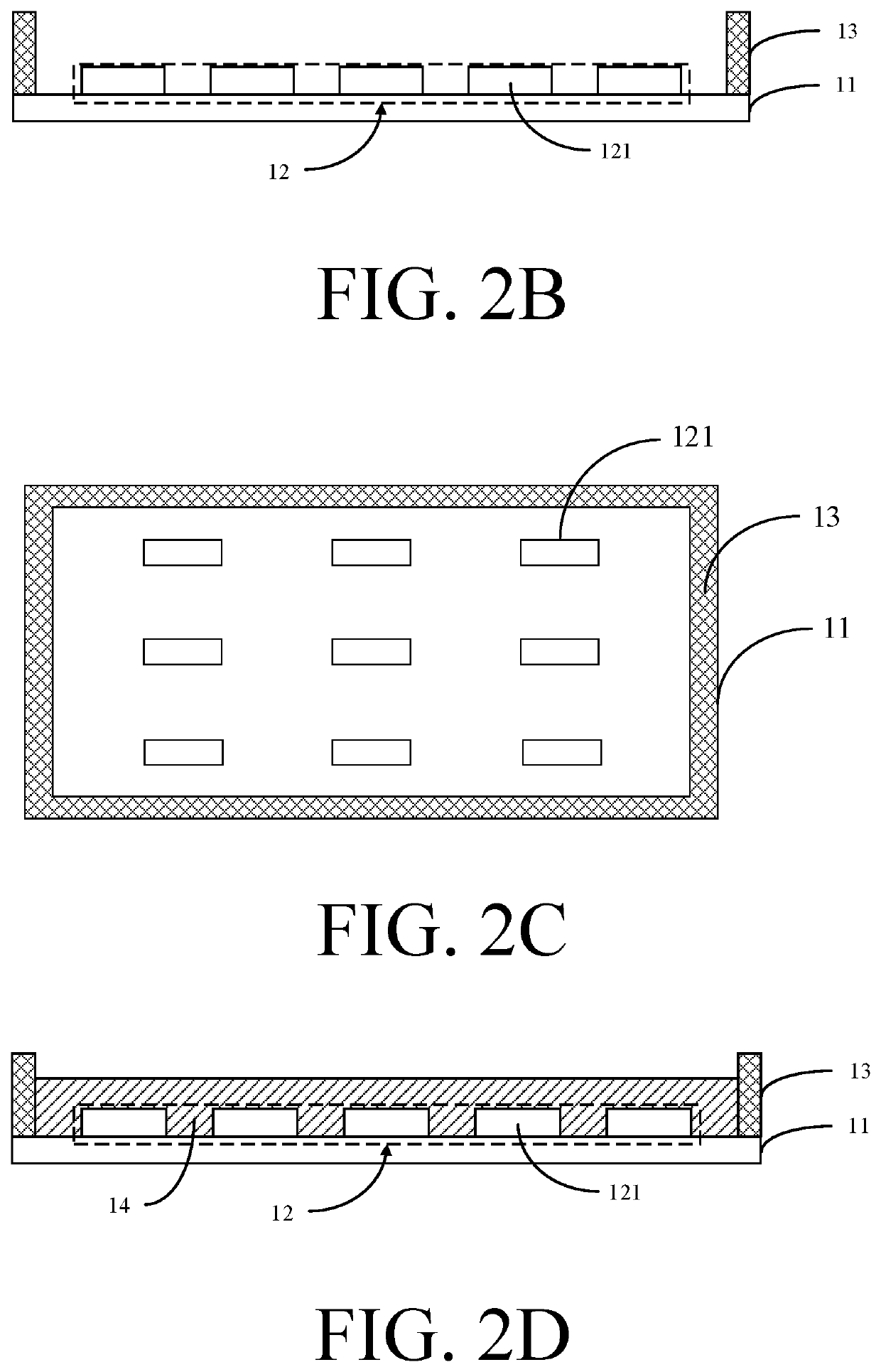

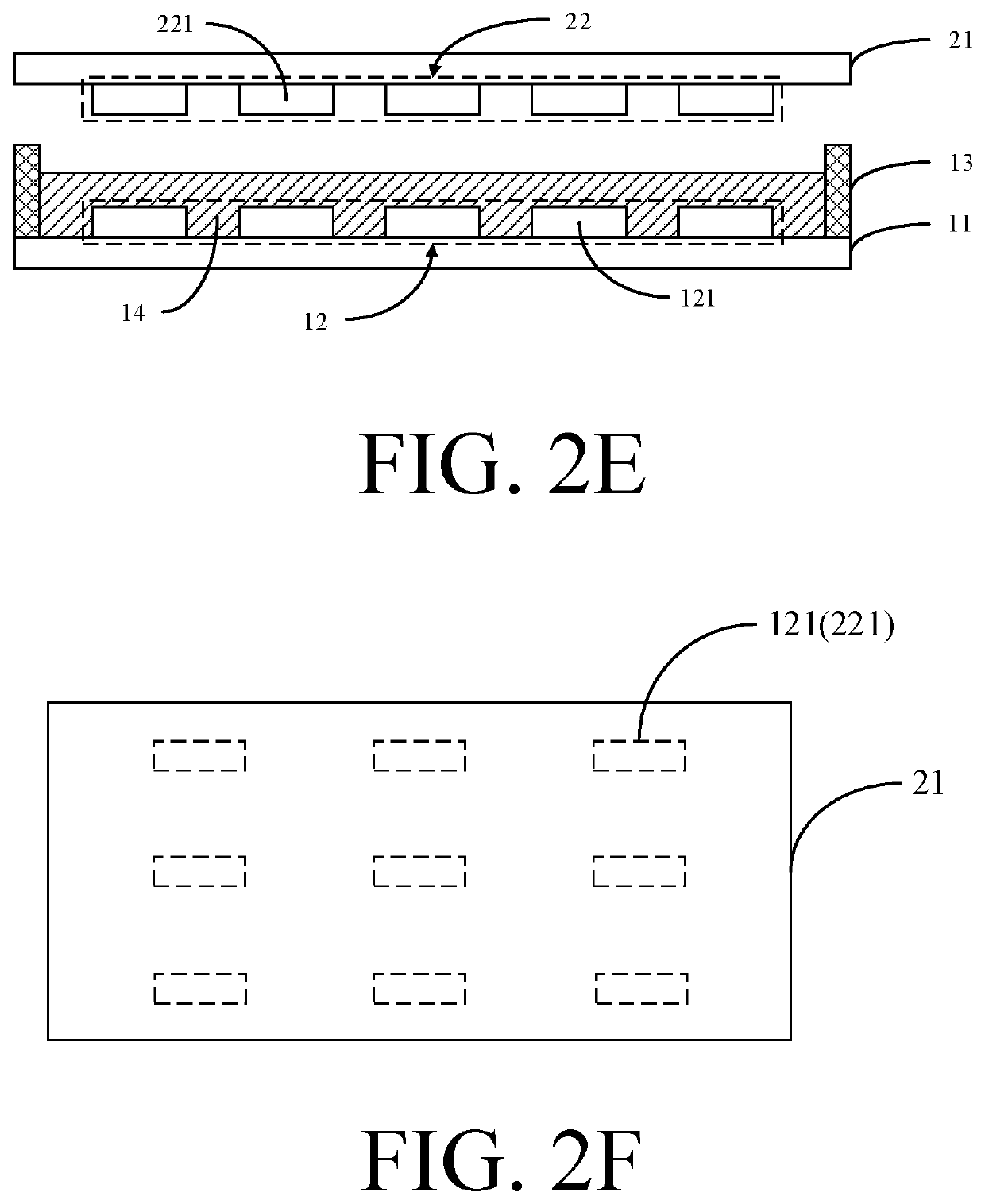

Manufacturing method of display panel

ActiveUS11414774B2Simplify the patterning processImprove productivityCircuit optical detailsElectrophoretic coatingsEngineeringNanotechnology

The present disclosure provides a manufacturing method of a display panel which includes forming a pattern of a first electrode layer on a first substrate; coating a nano particle solution on the pattern of the first electrode layer and the first substrate; providing a second substrate formed with a pattern of a second electrode layer, wherein the pattern of the first electrode layer corresponds to the pattern of the second electrode layer; and connecting the pattern of the first electrode layer and the pattern of the second electrode layer to a power supply to perform a patterning treatment on the nano particle solution to make the nano particle solution form a pattern of a nano particle layer.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

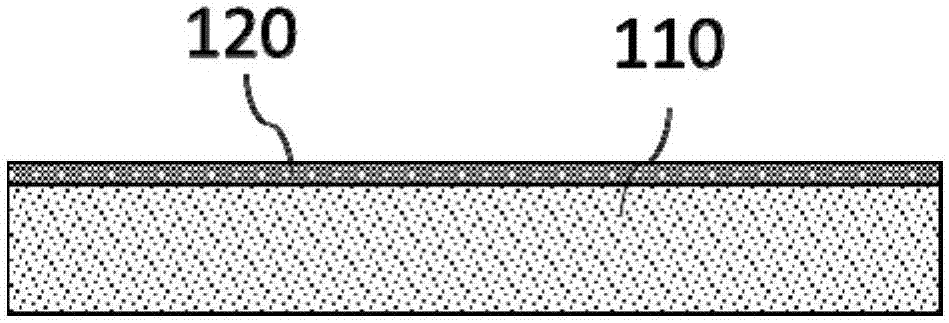

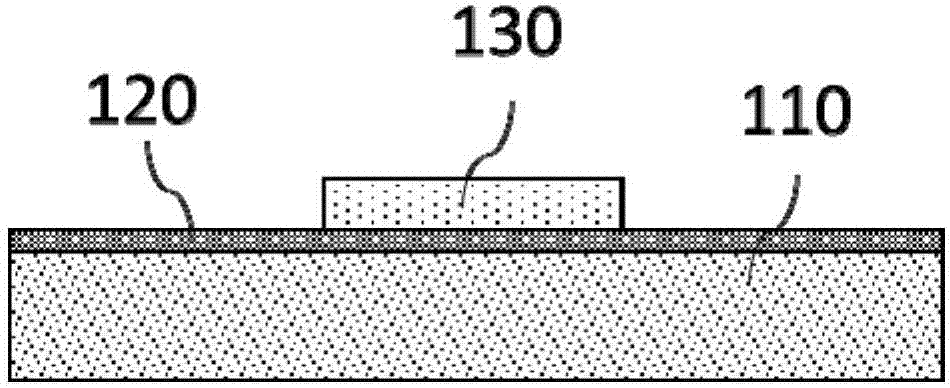

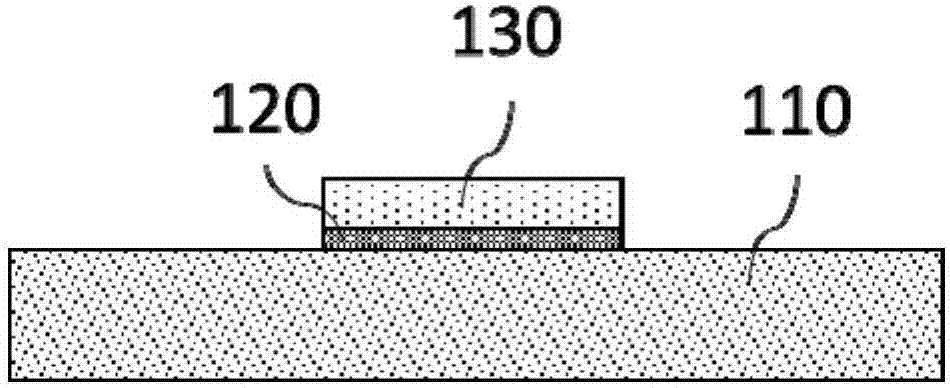

Method for patterning a surface of a substrate

PendingUS20220076952A1Simplify the patterning processSimple processSemiconductor/solid-state device manufacturingChemistryApparent viscosity

A method for patterning a surface of a substrate includes applying a liquid on the surface of the substrate, wherein an apparent viscosity of the liquid depends on a field strength applied to the liquid; applying a field to the liquid, wherein a field strength of the applied field is spatially varied in the liquid in a direction parallel to the surface of the substrate, thereby generating a spatially varied apparent viscosity distribution in the liquid in response to the applied field; and patterning the surface of the substrate by subjecting the surface to a surface modifying process, while maintaining the field and using portions of the liquid having apparent viscosities higher than a predetermined value as a mask; wherein the surface modifying process comprises removing material of the surface of the substrate and / or depositing material on the surface of the substrate.

Owner:INL INT IBERIAN NANOTECHNOLOGY LAB

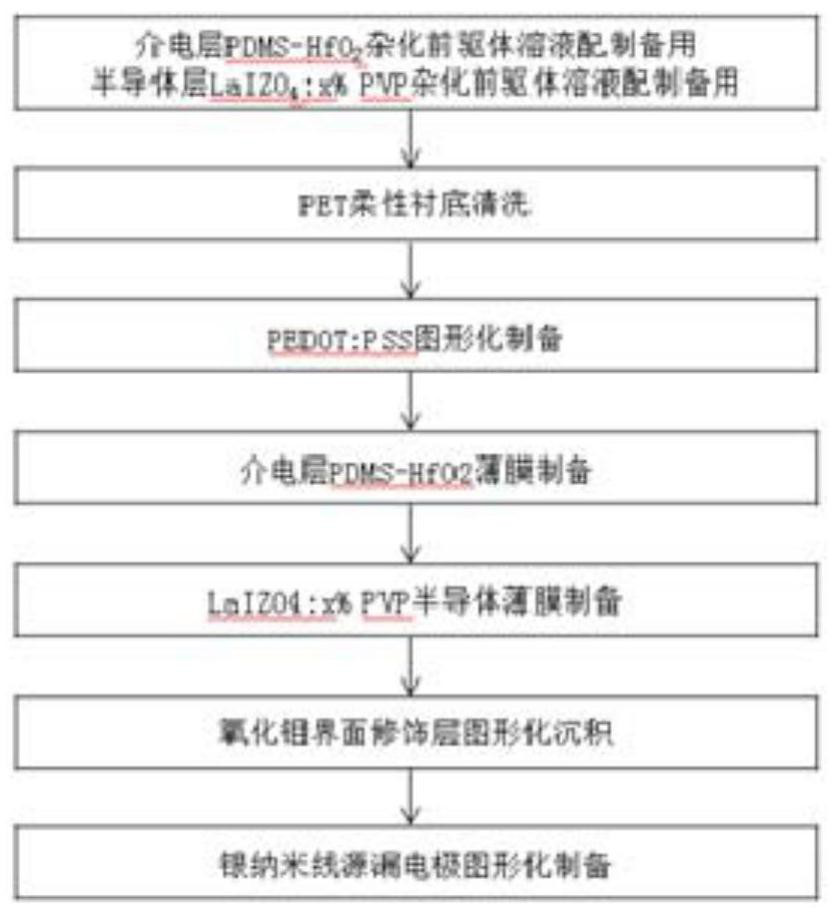

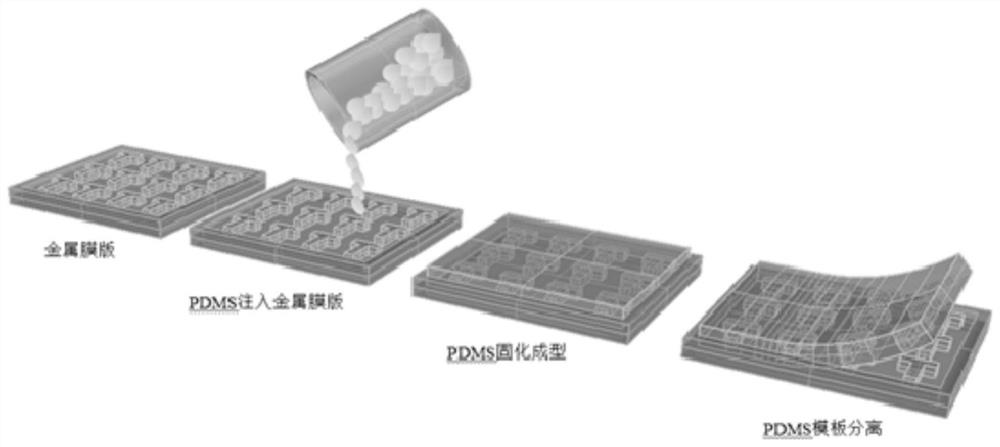

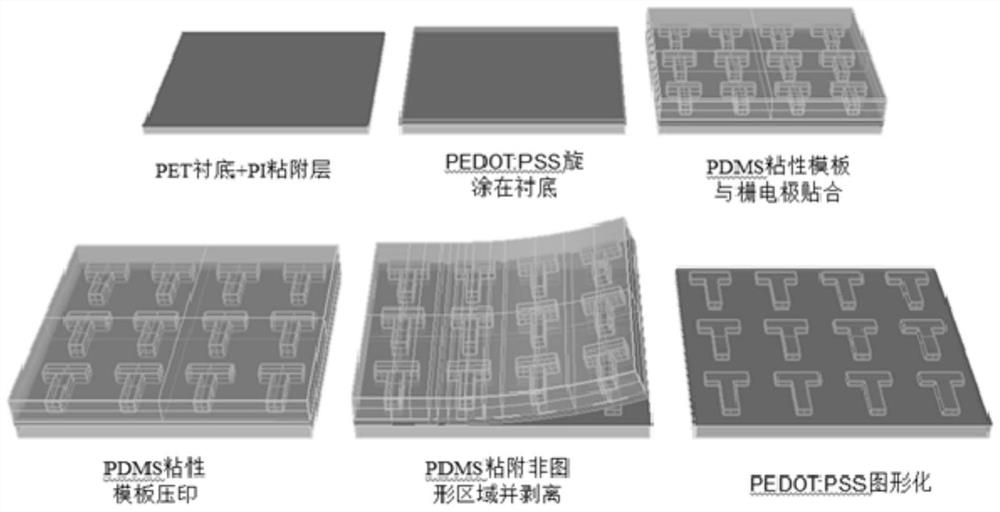

Flexible TFT device and preparation method thereof

PendingCN111900252AReduce deformationImprove stabilityFinal product manufactureSolid-state devicesHybrid materialEngineering

The invention discloses a flexible TFT device and a preparation method thereof. The flexible TFT device sequentially comprises a flexible substrate, a PI adhesion layer, a gate electrode, a dielectriclayer, a PalphaMS modification layer, a semiconductor layer, an interface modification layer and a source and drain electrode layer, wherein the gate electrode contains PEDOT: PSS, the dielectric layer contains a PDMS-HfO2 hybrid material, and the semiconductor layer contains a lanthanum indium zinc oxide-polytetravinylphenol hybrid material. By adopting the organic and inorganic hybrid system material and the TFT device structure, the problems of film layer cracks, displacement and the like caused by bending of the device are reduced, so that the bending resistance and the stability of the flexible TFT device are improved, and the service life of the flexible TFT device is prolonged.

Owner:GUANGDONG INST OF SEMICON IND TECH

Method of manufacturing thin film transistor, thin film transistor manufactured by the method, and display device employing the same

ActiveCN1832220BImprove patterning accuracySimplify the patterning processTransistorSolid-state devicesDisplay deviceEngineering

A method of manufacturing a thin film transistor is capable of enhancing pattern precision of an organic semiconductor layer and simplifying a patterning process. The method includes forming an organic insulating film on a substrate and forming a bank having the first and second concave portions and a third concave portion in the organic insulating film, the third concave portion being formed on the first and second concave portions. The method further includes forming a source electrode and a drain electrode in the first and second concave portions and forming an active layer in the third concave portion, the active layer contacting the source electrode and the drain electrode.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com