Method of manufacturing thin film transistor, thin film transistor manufactured by the method, and display device employing the same

A technology for thin film transistors and display devices, which can be used in the manufacture of transistors, semiconductor/solid-state devices, and electric solid-state devices, etc., and can solve problems such as crosstalk, high probability of particle generation, and difficulty in patterning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0035] First, refer to Figure 1A to Figure 1F and figure 2 A method of manufacturing a TFT according to a first embodiment of the present invention is described.

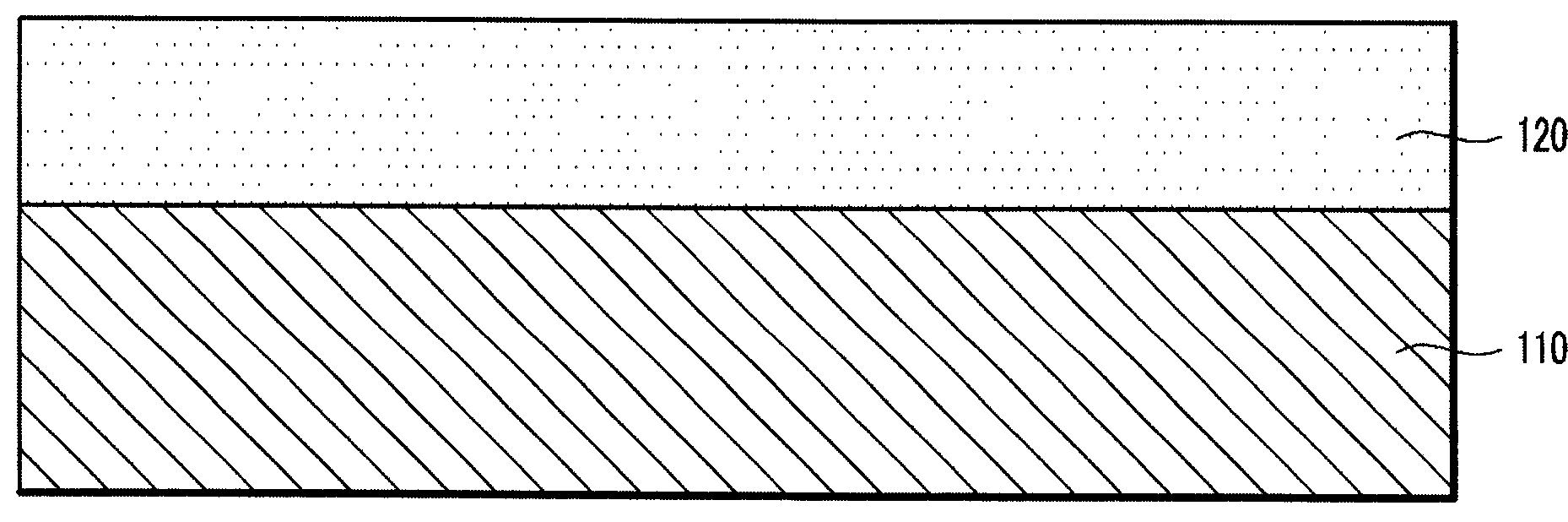

[0036] see Figure 1A , the organic insulating film 120 is coated on the substrate 110 . The substrate 110 may be made of an insulating material such as glass or plastic, or a metallic material such as stainless steel (SUS). Plastics can be polyethylene terephthalate (PET), polyethylene 2,6-naphthalate (PEN), polyethersulfone (PES), polyetherimide, polyphenylene sulfide ( PPS), polyarylate (PAR), polyimide, polycarbonate (PC), polyacrylate, cellulose triacetate and cellulose acetate propionate (CAP), etc. The organic insulating film 120 may be made of negative photoresist.

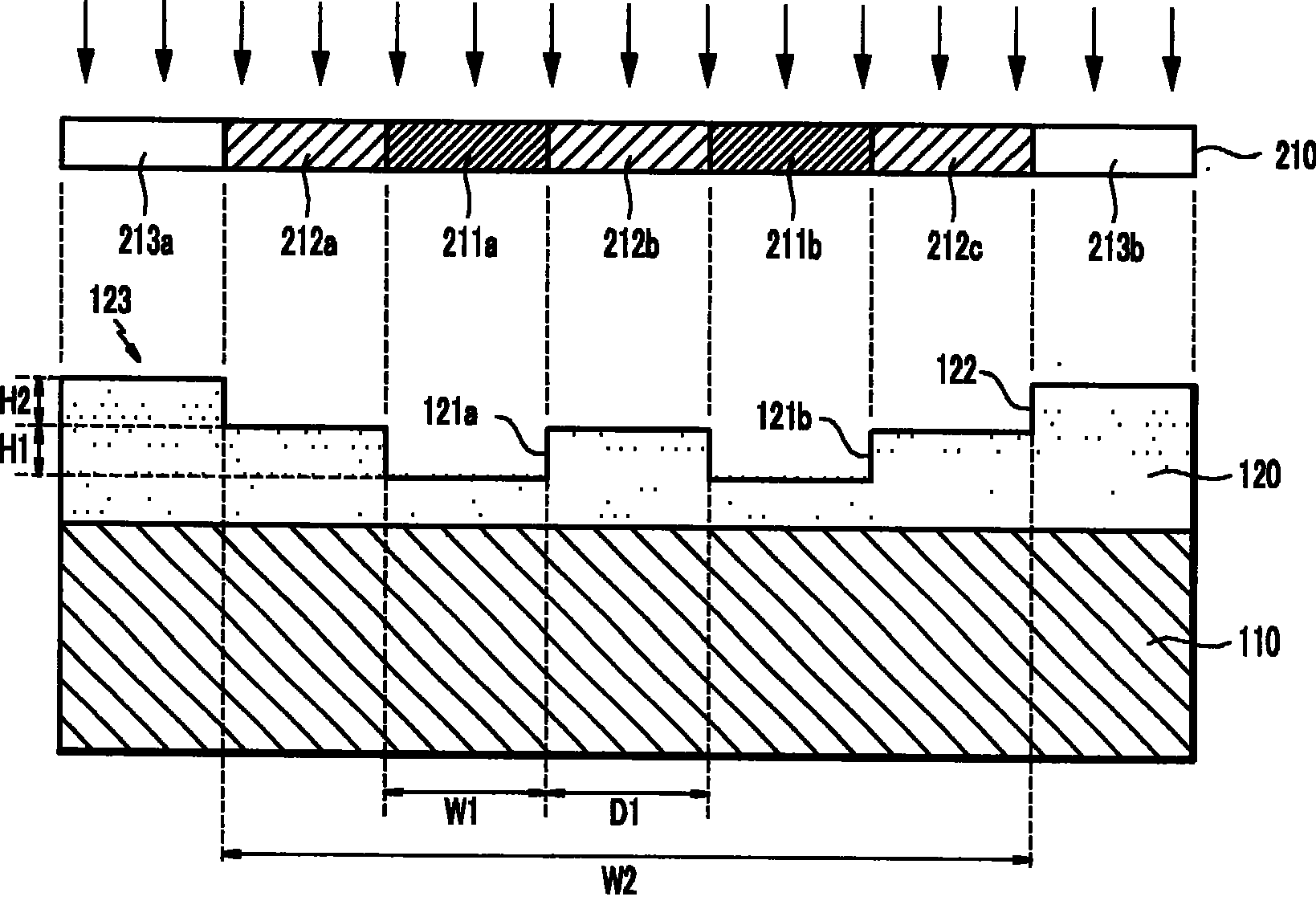

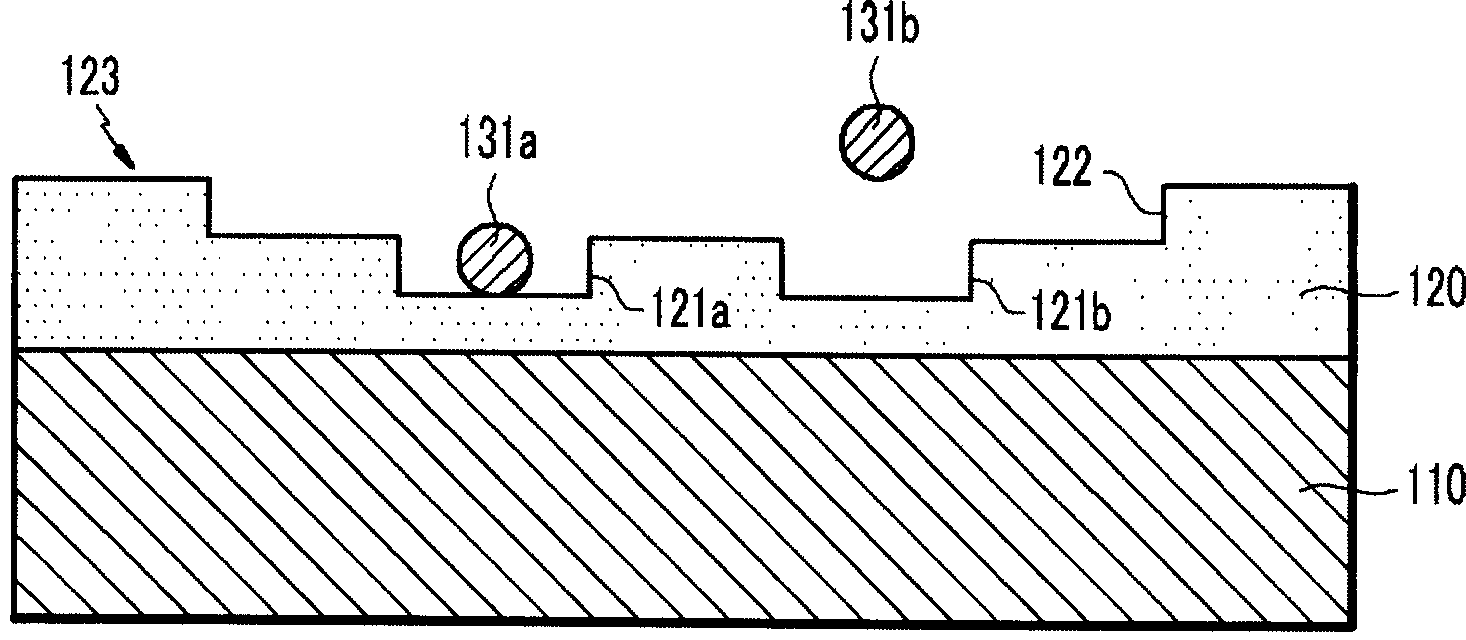

[0037] see Figure 1B , the organic insulating film 120 is exposed using a half-tone mask 210, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com