Composite transparent conductive film and preparation method thereof

A transparent conductive film, transparent conductive technology, applied in the direction of equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive layers on insulating carriers, etc., can solve the problem of unfavorable large-scale patterning of thin films Improve performance, affect carrier injection and other issues, achieve enhanced conductivity and electrical stability, strong corrosion resistance, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

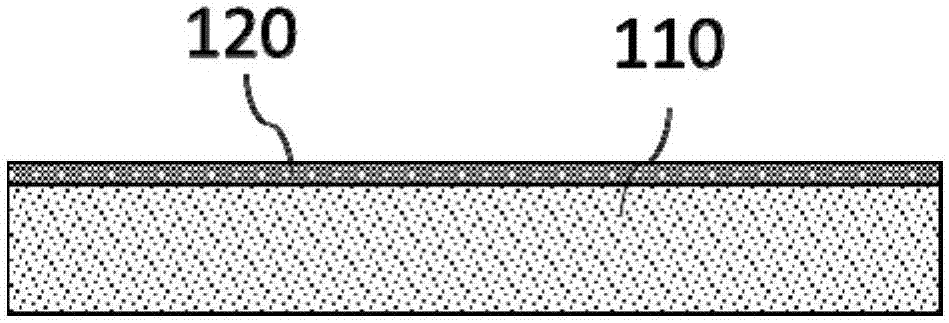

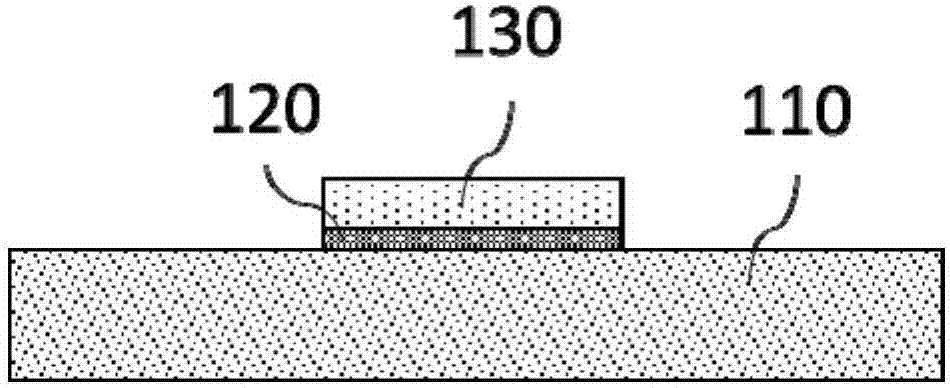

[0033] A composite transparent conductive film, which is composed of a transparent oxide layer and a thin metal layer stacked, wherein the thin metal layer is located under the transparent oxide layer, the thickness of the thin metal layer is 3-30nm, the thin metal layer is in a transparent state, and the thin metal layer Nanopores are present in the layer; during the preparation of the transparent oxide layer, the transparent conductive oxide is able to penetrate through the nanopores and come into contact with the substrate.

[0034] The concrete preparation method of this composite transparent conductive film is:

[0035] In step (1), one or more thin metal layers are prepared by coating or vacuum coating without patterning the prepared thin metal layers.

[0036] Among them, the thickness of the thin metal layer is controlled within 30nm. On the one hand, the metal film is in a transparent state; of adhesion. In addition, it can also avoid the peeling off of the whole pi...

Embodiment 2

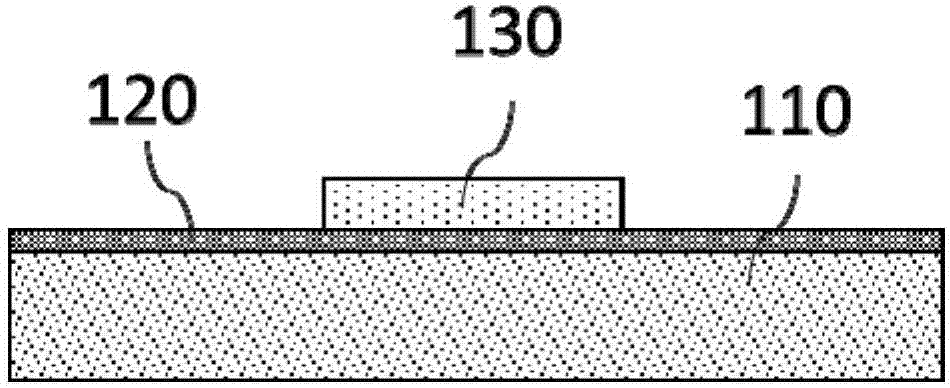

[0047] A patterned ITO / Au composite transparent conductive film was prepared and used as an electrode.

[0048] Such as figure 1 As shown, firstly, a layer of Au thin film 120 with a thickness of 10 nm is deposited on a glass substrate 110 . Next, if figure 2 As shown, after the Au film is treated with plasma for 5 minutes, ITO ink is directly inkjet printed on it. The atomic number ratio of Sn and In is 10 / 90 to form an ITO precursor film pattern 130, and the precursor pattern is annealed at 350°C for 1 hour. Finally, an ITO transparent conductive oxide film pattern with a line width of 70 μm and a thickness of 30 nm is formed. Thereafter, the entire film was placed in water for ultrasonic treatment for 2 min, and then dried with nitrogen to obtain the following: image 3 For the composite transparent conductive film shown, the square resistance of the film is

[0049] The composite transparent conductive film has low resistivity and good conductivity, and is suitabl...

Embodiment 3

[0051] Fabrication of patterned AZO / Pt composite transparent electrodes.

[0052] Such as figure 1 As shown, first a layer of Pt film 120 with a thickness of 8 nm is evaporated on the glass substrate 110, and then, as figure 2 As shown, after the Pt film is treated with UV for 5 minutes, AZO ink is directly ink-jet printed on it, wherein the ratio of the atomic number of Al to Zn is 3 / 97, forming an AZO precursor film pattern 130, and the precursor pattern is annealed at 350°C After 1 hour, an AZO transparent conductive oxide film pattern with a line width of 80 μm and a thickness of 40 nm was formed. Thereafter, the entire film was put into an aqueous hydrogen peroxide solution for ultrasonication for 3 min, and then dried with nitrogen to obtain the following: image 3 For the composite transparent conductive film shown, the square resistance of the film is

[0053] The composite transparent conductive film has low resistivity and good conductivity, and is suitable for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com