Film transistor with copper wire structure and its manufacturing method

A technology of thin film transistors and manufacturing methods, applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as difficult etching results, poor adhesion of insulating substrates, component failures, etc., to simplify the patterning process and reduce resistance value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

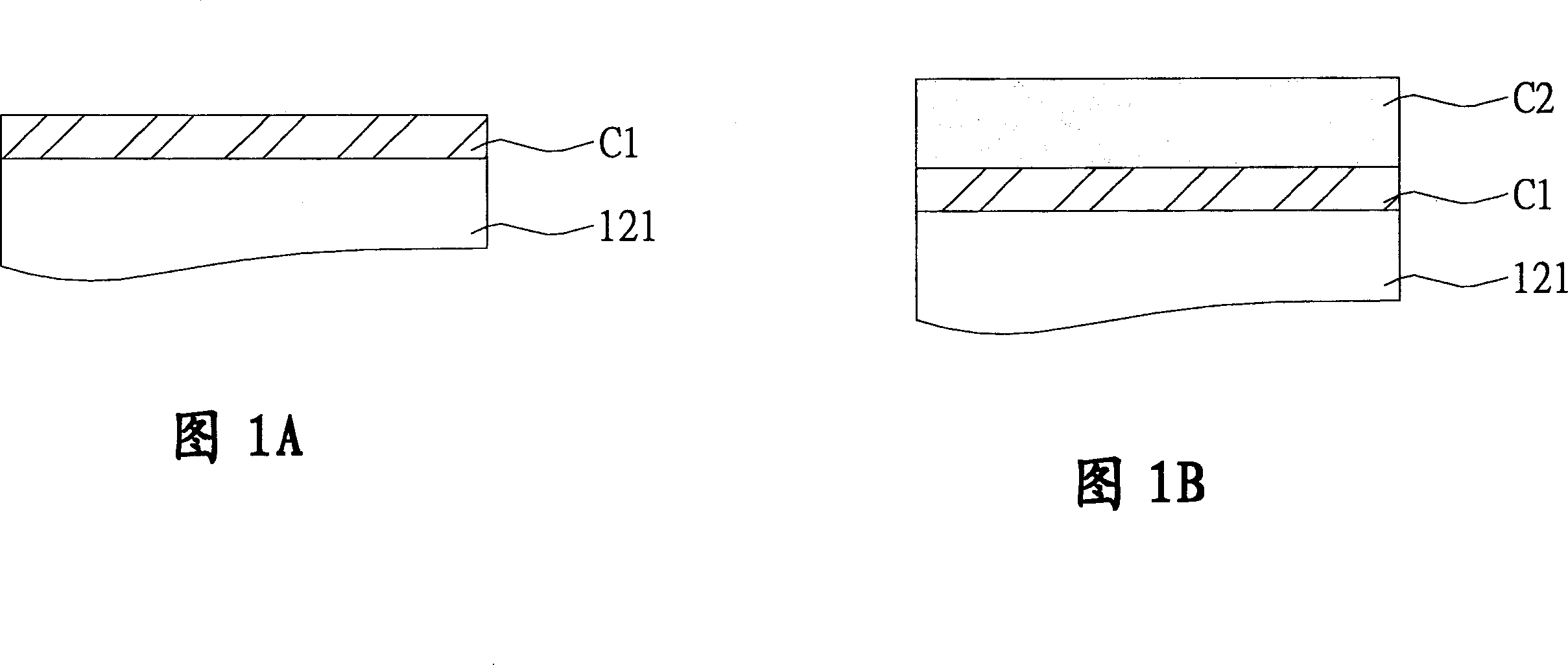

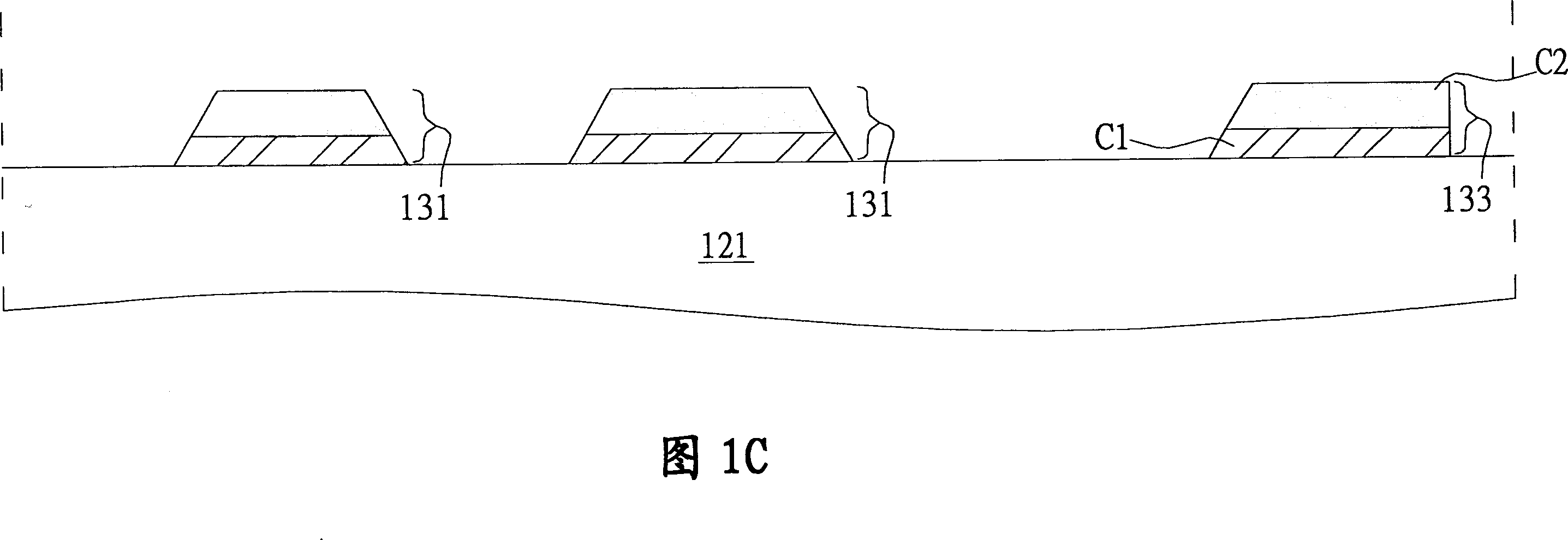

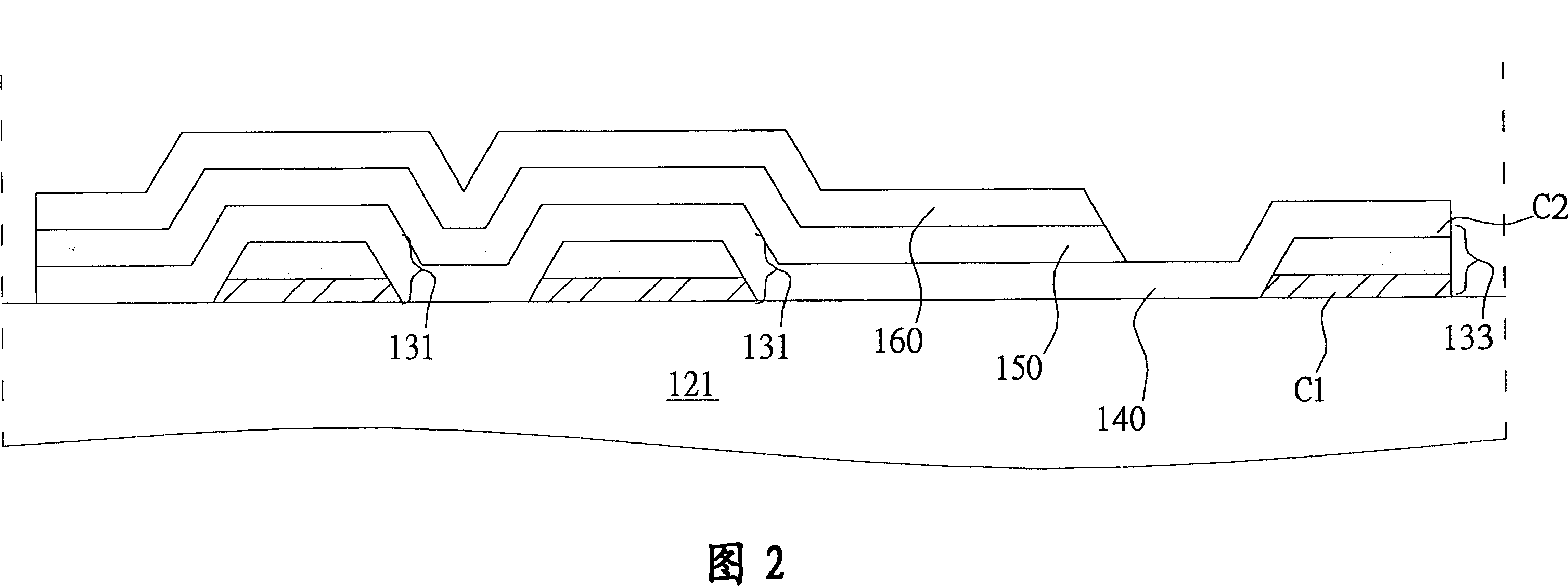

[0025] Please refer to FIG. 1A to FIG. 1C , which are process cross-sectional views of the gate of the double-layer metal structure of the present invention.

[0026] First, in an embodiment of the present invention where the gate 131 and the gate line 133 are generated, as shown in FIG. 1A to FIG. 1B , a substrate 121 is sequentially deposited to form a A copper alloy layer (copper alloy layer) C1 with a thickness of about 10 to 2000 angstrom and a copper layer (copper layer) C2 with a thickness of about 1000 to 4000 angstrom. Then, as shown in FIG. 1C, define the pattern of the double-layer metal structure such as the formed copper alloy layer C1 and copper metal layer C2, so as to produce a copper wire of the double-layer metal structure, and then perform heat treatment at a temperature of about 100 to 500° C. (heat treatment).

[0027] In another embodiment of the present invention for generating the gate 131 and the gate line 133, as shown in FIG. 1A to FIG. 1B, a layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com