Novel thread trimming and sock turning all-in-one machine

An all-in-one machine and thread trimming mechanism technology, which is applied in mechanical cleaning, fabric surface trimming, textile and paper making, etc., can solve the problems of low thread trimming efficiency, difficult replacement and maintenance, and slow speed, so as to reduce blind spots and facilitate maintenance And the effect of replacing and increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

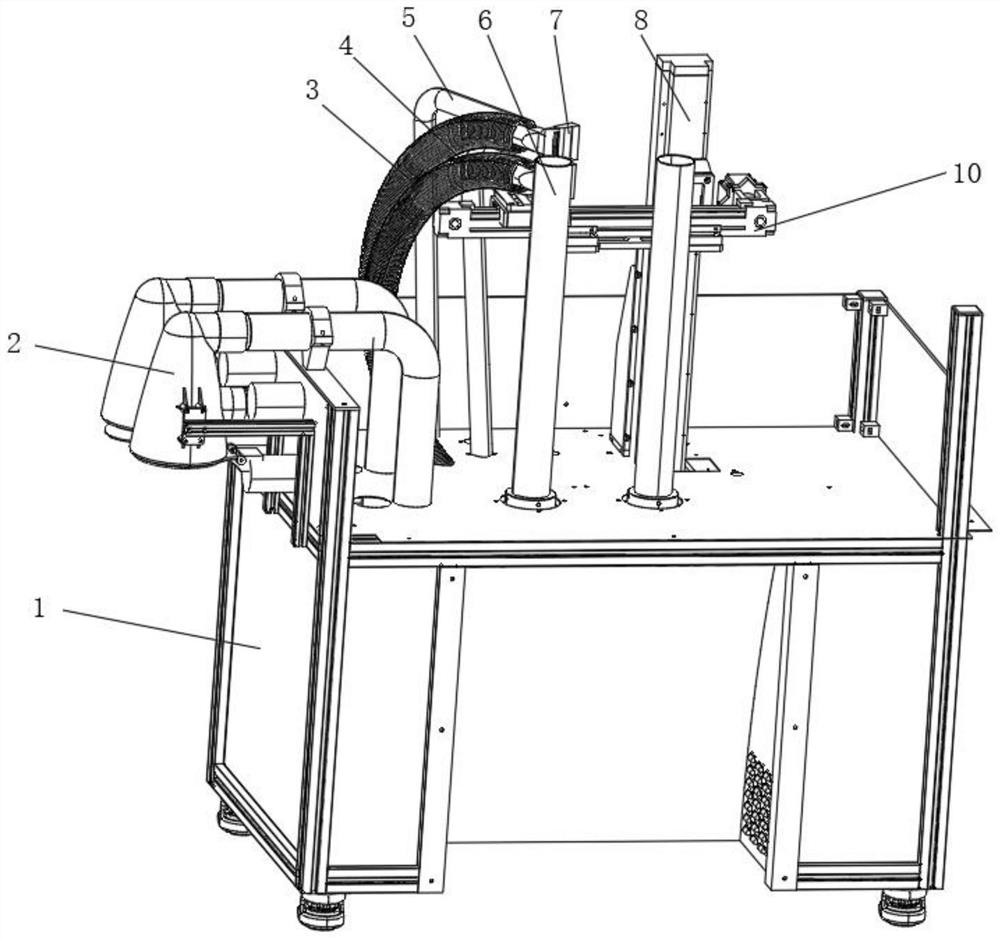

[0026] This embodiment provides the specific structure of a new type of thread trimmer and hosiery turning all-in-one machine, such as figure 1 As shown, it includes a device main body 1, two sock tubes 6 for socketing socks are installed on the top of the device main body 1, and a sock output device 2 is also arranged on the device main body 1, and the sock output device 2 is connected to the bottom of the sock tube 6;

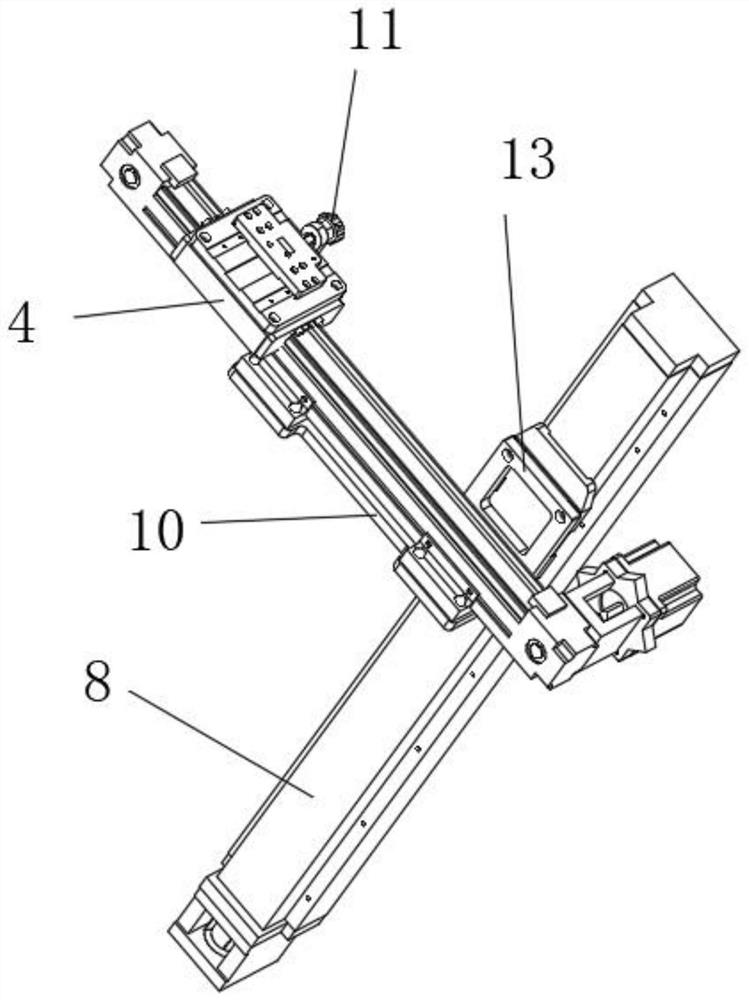

[0027] The top of the main body 1 of the device is located on one side of the sock tube 6 and is provided with a vertical electric rail 8, on which the vertical electric rail 8 is slid and engaged with a vertical sliding seat 13, on which the horizontal electric rail 10 is fixed, and the horizontal electric rail 10 is The electric rail 10 is slidingly engaged with a horizontal sliding seat 4, and the horizontal sliding seat 4 is detachably installed with a thread trimming mechanism for cutting the socks socketed on the sock tube 6.

[0028] By adopting the ab...

Embodiment 2

[0031] This embodiment provides the specific structure of a new type of thread trimmer and hosiery turning all-in-one machine, such as Figure 1-5 As shown, it includes a device main body 1, two sock tubes 6 for socketing socks are installed on the top of the device main body 1, and a sock output device 2 is also arranged on the device main body 1, and the sock output device 2 is connected to the bottom of the sock tube 6;

[0032] The top of the main body 1 of the device is located on one side of the sock tube 6 and is provided with a vertical electric rail 8, on which the vertical electric rail 8 is slid and engaged with a vertical sliding seat 13, on which the horizontal electric rail 10 is fixed, and the horizontal electric rail 10 is The electric rail 10 is slidingly engaged with a horizontal sliding seat 4, and the horizontal sliding seat 4 is detachably installed with a thread trimming mechanism for cutting the socks socketed on the sock tube 6.

[0033] Thread trimming...

Embodiment 3

[0038] This embodiment provides the specific structure of a new type of thread trimmer and hosiery turning all-in-one machine, such as Figure 1-5 As shown, it includes a device main body 1, two sock tubes 6 for socketing socks are installed on the top of the device main body 1, and a sock output device 2 is also arranged on the device main body 1, and the sock output device 2 is connected to the bottom of the sock tube 6;

[0039] The top of the main body 1 of the device is located on one side of the sock tube 6, and a vertical electric rail 8 is provided. A vertical slide seat 13 is installed on the vertical electric rail 8, and a horizontal electric rail 10 is fixed on the vertical slide seat 13. The electric rail 10 is slidingly engaged with a horizontal sliding seat 4, and the horizontal sliding seat 4 is detachably installed with a thread trimming mechanism for cutting the socks socketed on the sock tube 6.

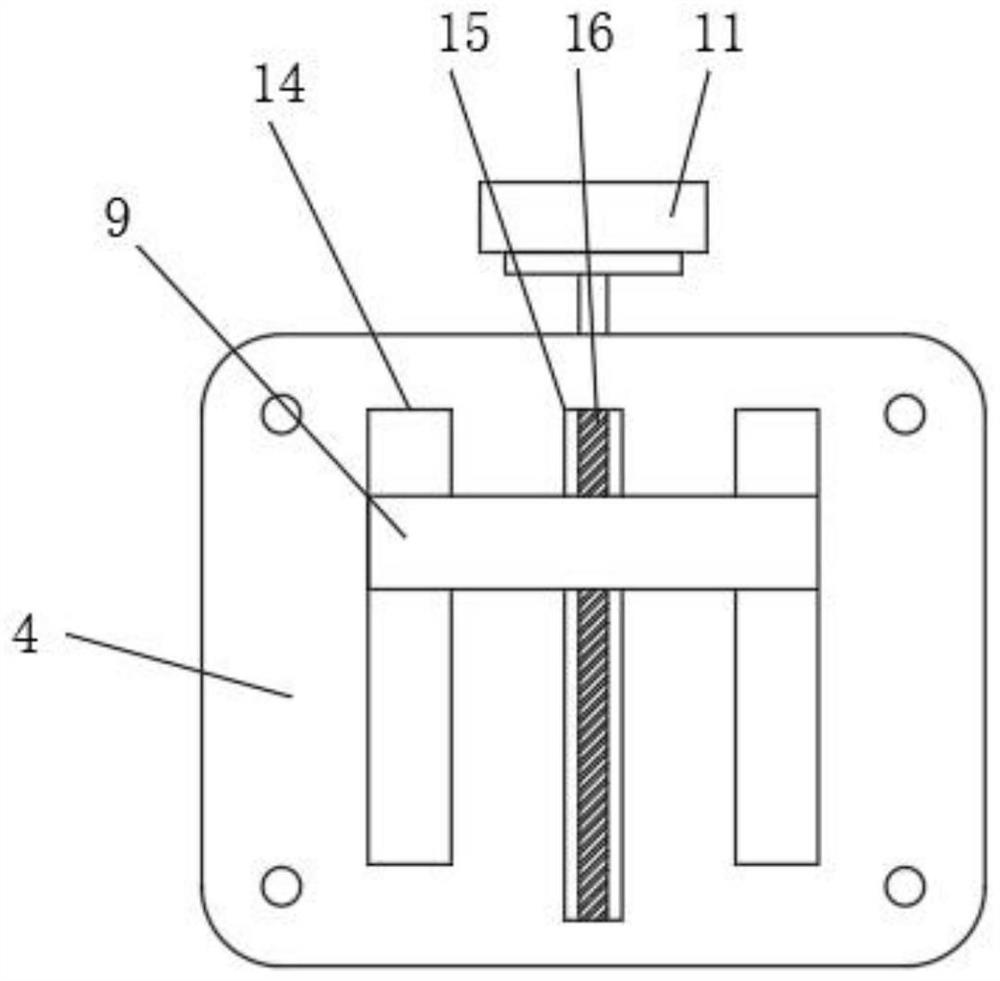

[0040] Thread trimming mechanism comprises upper cutter head 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com