Ultralow-temperature cryogenic top-entry ball valve with built-in pressure release valve

A pressure relief valve, ultra-low temperature technology, applied in the direction of cocks, valve details, safety valves, etc. including cut-off devices, can solve the problems of low reliability, achieve high reliability, avoid uncertainty, reasonable structure and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

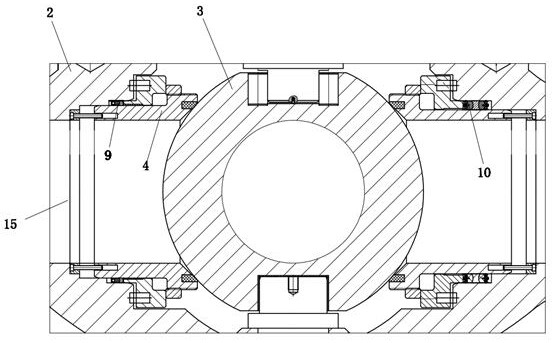

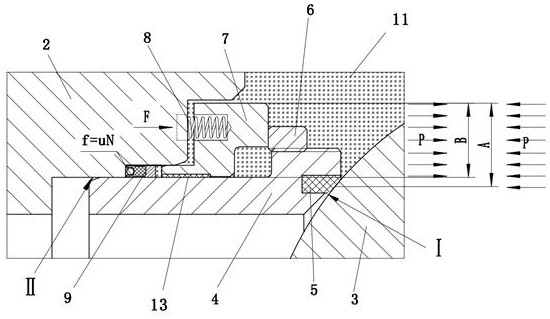

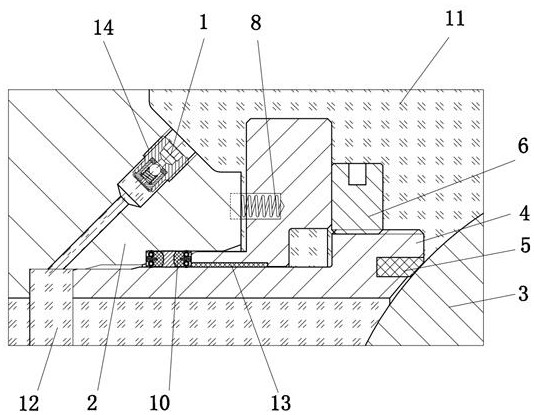

[0028] refer to Figure 1-4 , an ultra-low temperature cryogenic top-loading ball valve with a built-in pressure relief valve, comprising a valve body 2, a fluid passage 15 and a valve stem passage interconnected in the valve body 2, a ball 3 arranged in the fluid passage 15, and a valve stem passage One end away from the fluid channel 15 is covered with a bonnet, the valve stem channel is provided with a valve stem, the side of the valve stem close to the fluid channel is connected to the sphere 3, and the end of the valve stem away from the sphere 3 passes through the valve stem channel and passes out of the valve. A valve seat 4 is respectively installed between the two sides of the sphere 3 and the valve body 2, the upstream end of the valve seat 4 is provided with a two-way pan plug 10, and the valve body 2 adjacent to the two valve seats 4 is provided with a The one-way pressure relief valve installation holes 2 for communicating with the fluid channel 15 and the middle ...

Embodiment 2

[0032] refer to Figure 1-4, as another preferred embodiment of the present invention, the difference from Embodiment 1 is that Embodiment 1 is suitable for places where the number of opening and closing of cryogenic ball valves installed on the cryogenic pipelines of natural gas liquid plants and LNG receiving stations is relatively frequent, if If the cryogenic ball valve installed in the device system is in a normally open state, this scheme can be selected. The principle is: a one-way drain connected to the fluid passage 15 is designed on the upper part of the ball 3 adjacent to the two valve seats 4. Pressure valve 1. Because the valve installed in the cryogenic device system is normally open, the abnormally elevated pressure in the middle cavity can be released into the channel. Among them, when the size of the ball is Sφ86~Sφ135mm, the one-way pressure relief valve of 1 / 8-27NPT can be selected; when the size of the ball is Sφ135~Sφ250mm, the one-way pressure relief val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com