Pipeline robot based on defect detection

A pipeline robot and defect detection technology, applied in pipeline systems, special pipes, pipe components, etc., can solve the problems of inconvenient movement of pipeline robots, difficulty in realizing all-round inspection, and inconvenient adjustment of size, etc., to achieve no dead angle detection, structure Simple, sharpness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

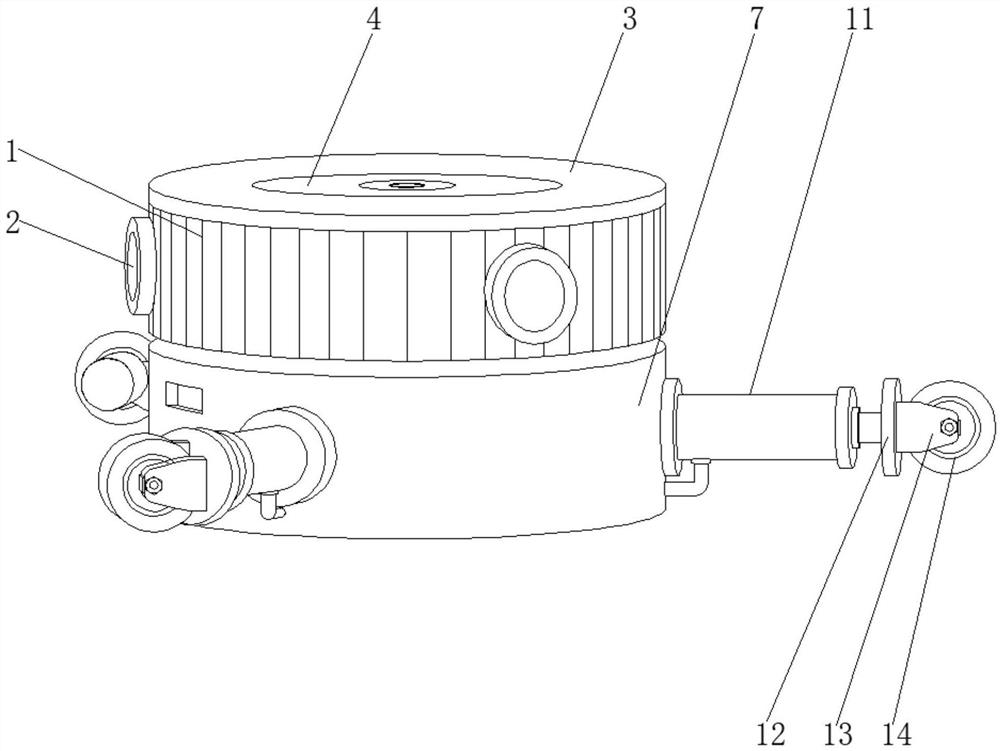

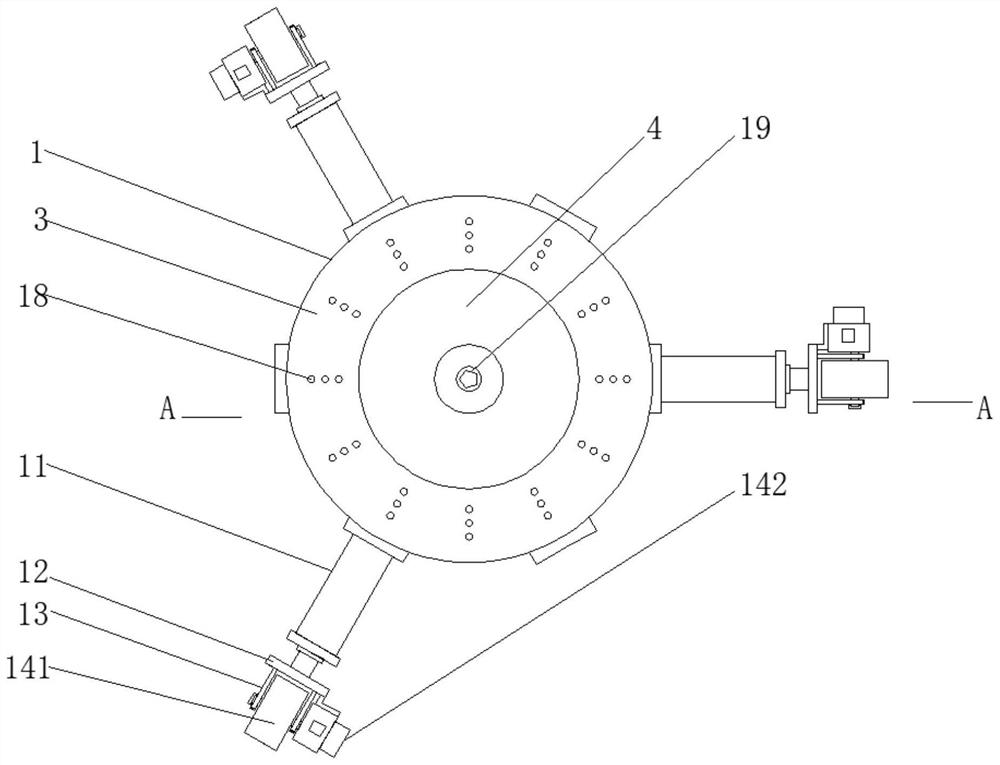

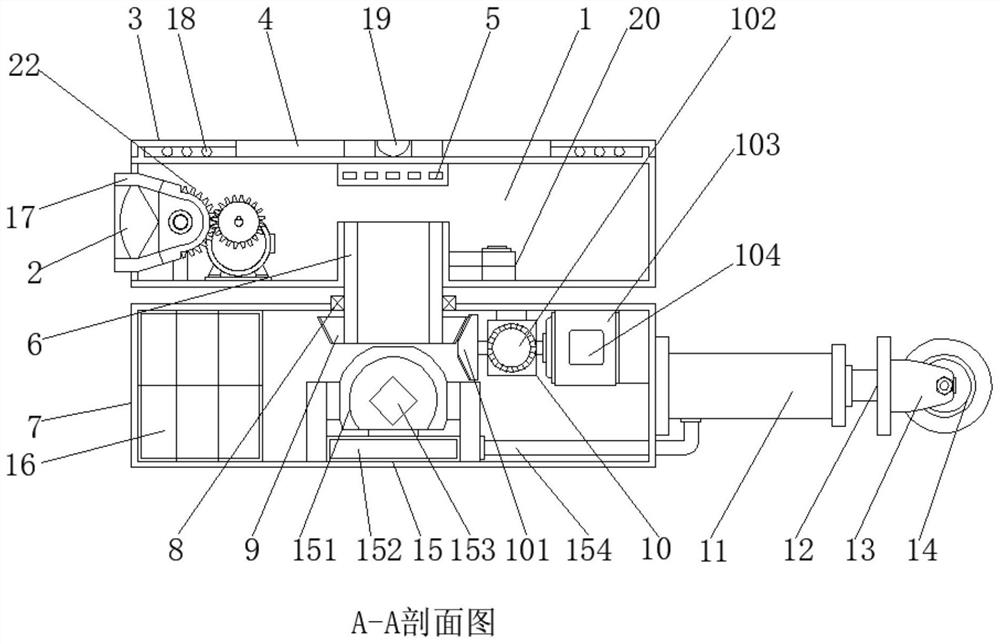

[0055] See Figure 1-6 , A pipeline robot based on defect detection, including:

[0056] The detection cartridge 1, the outer side surface of the detecting box 1 is uniformly installed with three cameras 2;

[0057] The fill light cover 3, the thread is connected above the detecting cassette 1, the structure of the finite light cover 3 is a transparent structure, and the innermost position of the filling lamp cover 3 is fixed in the inner circular plate 4;

[0058]The controller 5 is mounted to the inside top of the detectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com