Planar transmission line structure for improving ferromagnetic resonance linewidth test precision

A technology of planar transmission lines and ferromagnetic resonance lines, applied in measuring devices, using electromagnetic means, instruments, etc., can solve the problems of increasing signal line width, large dielectric loss, and poor signal isolation, so as to eliminate return loss, The dielectric constant is moderate and the effect of improving the test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

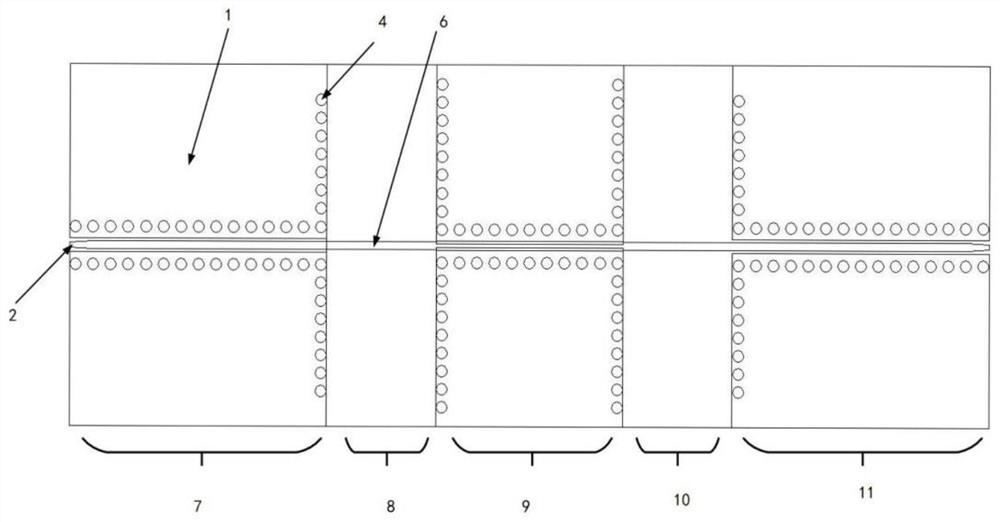

[0029] This embodiment proposes a planar transmission line structure that improves the test accuracy of ferromagnetic resonance line width, such as figure 1 , 2, including the first-level standard characteristic impedance grounded coplanar waveguide 7, the first-level non-standard microstrip line 8, the intermediate level non-standard characteristic impedance grounded coplanar waveguide 9, and the second-level non-standard microstrip line in series. The line 10 and the second-level standard characteristic impedance grounded coplanar waveguide 11; the overall length of the planar transmission line structure is 31.5mm, and the width is 12mm.

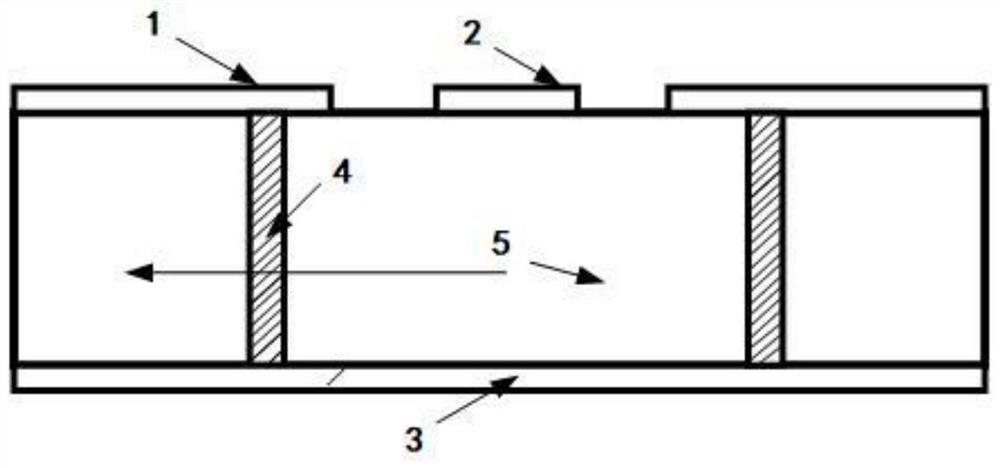

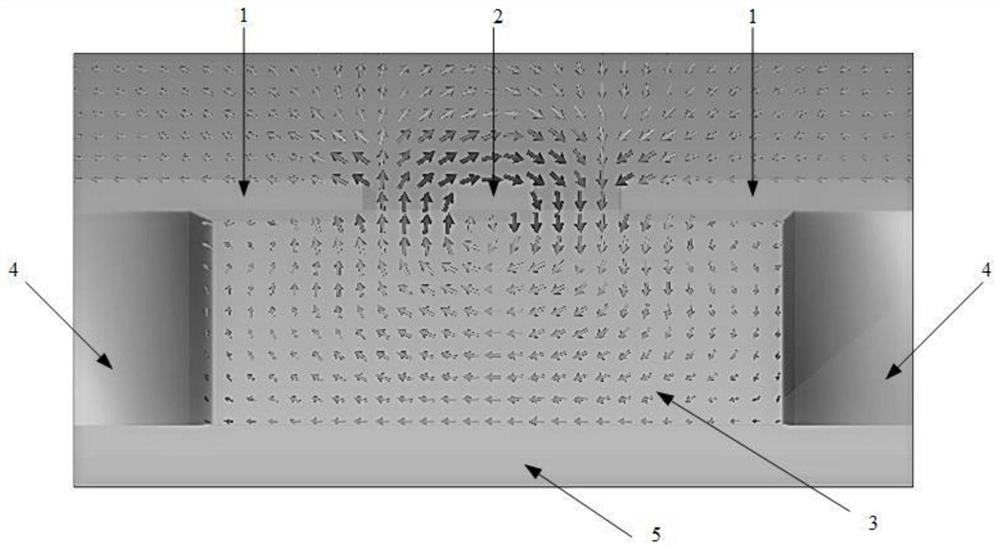

[0030] The first-level standard characteristic impedance grounded coplanar waveguide 7, the first-level non-standard microstrip line 8, the intermediate level non-standard characteristic impedance grounded coplanar waveguide 9, the second-level non-standard microstrip line 10 and the second-level standard The dielectric substrate 5 of the ...

Embodiment 2

[0042] This embodiment proposes a planar transmission line structure that improves the accuracy of ferromagnetic resonance linewidth testing, including the first-level standard characteristic impedance grounded coplanar waveguide 7, the first-level non-standard microstrip line 8, and the intermediate-level non-standard The characteristic impedance grounded coplanar waveguide 9, the second non-standard microstrip line 10 and the second standard characteristic impedance grounded coplanar waveguide 11; the overall length of the planar transmission line structure is 31.5mm, and the width is 12mm.

[0043] The first-level standard characteristic impedance grounded coplanar waveguide 7, the first-level non-standard microstrip line 8, the intermediate level non-standard characteristic impedance grounded coplanar waveguide 9, the second-level non-standard microstrip line 10 and the second-level standard The dielectric substrate 5 of the characteristic impedance grounded coplanar wavegu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com